Table of Contents

This article will cover the wide spectrum of process improvement including what it is, how to do it, tools you can use, key concepts, considerations, examples and much more. Process improvement is an extremely helpful and powerful activity that can be conducted by anyone, at any level, in any industry and for any motivation.

When it comes to process improvement, even though there are tried and tested methods and tools which work, there is definitely not a one-size-fits-all approach. You must tailor your approach to the needs of your organisation, based on its size, its needs, its industry, its desired outcomes etc. A key tip to remember with process improvement is that the desired output will always drive the way in which you seek to realise these outputs.

I want you to leave the article with the fundamental knowledge of and confidence to deploy process improvement, or at least approach it in a less cautious way. Given that process improvement can lead to large-scale, fundamental change, many are wary of embarking on the endeavour in the first place. This is a huge shame, as process improvement can reap some really substantial rewards. At the end of this article, you won’t have such reservations.

The fundamentals of process improvement

What is process improvement?

Process improvement is, at its heart, a way for you to take a process and move it from one state to another. The direction in which you move this process is, of course, in the right direction. The state you want to end up with is a more streamlined, efficient, effective, productive, less wasteful, less costly process. Often the phase people will use when it comes to process improvement is – “I want to be able to do the same, but for less”, or “I want to be able to produce more outputs for the same or less”. You ultimately want to be able to achieve your stated outcome in less time and with better quality outputs.

You can approach this topic at its most basic level, identifying that we are looking at “improving” our “process”. Process improvement is ultimately the output we want to see at the end of our work, but it is not necessarily what gets us there. How we achieve an improved process can come in many forms, using many tools and various approaches, all for the same aim. You can achieve process improvement in stages, so run process improvement projects one after the other, or you can seek to continually improve your processes, embarking on a continuous improvement mindset to achieve this.

Examples of process improvement

Example 1: Within your payroll process, you have a series of activities which explain the manual, human checking that occurs on the data. These activities take around 3 hours to complete each and every payroll run. To improve the process, we remove all of these activities from the manual and the human and develop a bot to conduct the checks instead. This means the checking activities can now take less than 1 minute, as the steps have now all been automated. This is an example of a process improvement which sees the process completed in less time, the risk is vastly reduced as the potential for human error has now been removed and time freed up for those who would have completed these tasks to now do more value-adding activities in this or other processes.

Example 2: Within our benefits process, we have a handful of steps that we have to hand over to our Talent Acquisition Team who need to check, validate and approve of data linked to new starters and their benefits selections. As we have to hand this part of the process over, wait and then see it handed back, there is substantial waiting time built into the process. Indeed, because of this handoff, the process takes around 2 hours longer to be completed than is necessary, as the Benefits Team have to wait for Talent Acquisition to check, validate and approve the data. To improve this process, we want to remove this handoff and therefore the waiting time altogether. If we change access to the system so the Benefits Team can access, validate and approve the data themselves, this removes the need for any handoff. By merging this process into one singular swim lane, you remove the handover waste altogether, saving a lot of time.

Example 3: Our billings process, sitting within the Finance Team, is producing many errors on a monthly basis. These errors are coming from the system (technical errors), the team (human errors) and the information being processed (data errors). With such errors comes the need to check, the root cause and fix the errors, each one of them. This is causing significant amounts of time to be wasted each and every process run having to check, root cause and fix. It is also leading to an increase in complaints from wider stakeholders and clients. To address this, a new system is brought in to remove the technical errors being seen, the team is better trained and upskilled to deliver the process better, and a data validation check is added to the process to ensure the data is correct. All of these changes ensure the process can run as anticipated and the errors seen do not reoccur in the future.

The importance of process improvement

There are many benefits to deploying process improvement within your organisation, and if done correctly, the rewards can ripple out across your organisation. This is important to remember – not only will what you do or change impact the immediate process, product or person, but that impact is likely to be felt more widely, especially if the process in question is cross-functional. This is why it is so important you deliver good, positive process improvement, and deliver it well. Just as those positive impacts can be felt across the wider organisation, so can any negative, wrong or mistaken changes. This is why it is so important when delivering process improvement, you deliver it with all affected stakeholders in mind.

If we acknowledge the benefits and the importance of process improvement, the list includes:

- Improved efficiency, effectiveness, quality, output, responsiveness and productivity.

- Reduced waste, errors, complaints, costs, waiting time and staff turnover.

- Better turnaround times, capacity, workflow, systems, working practices and transparency.

- No need to hire new staff, no issues caused, no poor team culture, no employee burnout and no backlogs of work

Also read: Why you must continually evaluate and improve business processes

Now, of course, not every process improvement will lead to all of these benefits, each and every time. However, you will realise many of them with each and every process improvement you deliver. It is important, if you are looking to realise benefits across many departments, you communicate out effectively what is being done, why it is being done and how this is going to impact those involved, positively.

Triggers of process improvement – how to spot when it is needed

When it comes to identifying the need for and delivering process improvement, it is not as simple as realising something is wrong and a process improvement is needed. Indeed, it can be the case that process improvement is not the way to go, but you need business or continuous improvement. Noticing you need to improve a process is often done by identifying there is a trigger – something is wrong or there is a need to do so. For example, some organizations will say “We want to reduce the number of steps in these processes by 20%”, as part of a wider efficiency drive. This is absolutely fine to do, if not sometimes a little tricky.

However, there are also going to be instances where there are some obvious signs process improvement is needed. Let’s look at some of those triggers now.

Trigger 1

The process in question is taking longer than usual to deliver its output (product or service). You have noticed where the process once took an average of 4 hours to complete, it now takes 6 and this has been consistent over recent times. This would indicate waste has been built into the process somewhere and somehow, and this needs to be addressed.

Trigger 2

We are seeing a number of repeat errors each time the process is run. These errors are consistent each time in terms of nature, volume and their impact on the wider process. There is also quite a bit of waste being produced because we have to go and fix the errors, deal with any complaints that have come from them and identify the right root causes.

Trigger 3

The quality of the final output (product) of the process is now consistently lower than it once was. This decline has been gradual but consistent over recent months, indicating something has gone wrong in the process and needs fixing.

Anytime there is an indication that your process is no longer performing as it once was, it not performing as you expect it to (including new processes) or the product/service is being negatively impacted in some way (quality, time to deliver etc.) this indicates a process improvement could very well be needed. Even though there could be problems with people, policies, procedures or the products themselves, you must investigate to see whether or not this is a trigger for a process improvement approach.

Additional triggers to call out here include- An audit review, where a recommendation has been submitted. A continuous process review, where a process owner has identified the need. A directive from management, who want to reduce time taken or number of people involved. Market pressures mean you now require your processes to evolve due to changing needs and expectations. A company merger, meaning a whole array of processes needs to be amalgamated and improved as part of this work. And, finally, cost reduction. If businesses are looking to reduce costs, improving processes can be a great way to find efficiencies which can ultimately be turned into hard cash savings.

Also Read: Process Improvement Plans: An all-inclusive 8 step guide

Finding the value, and the non-value

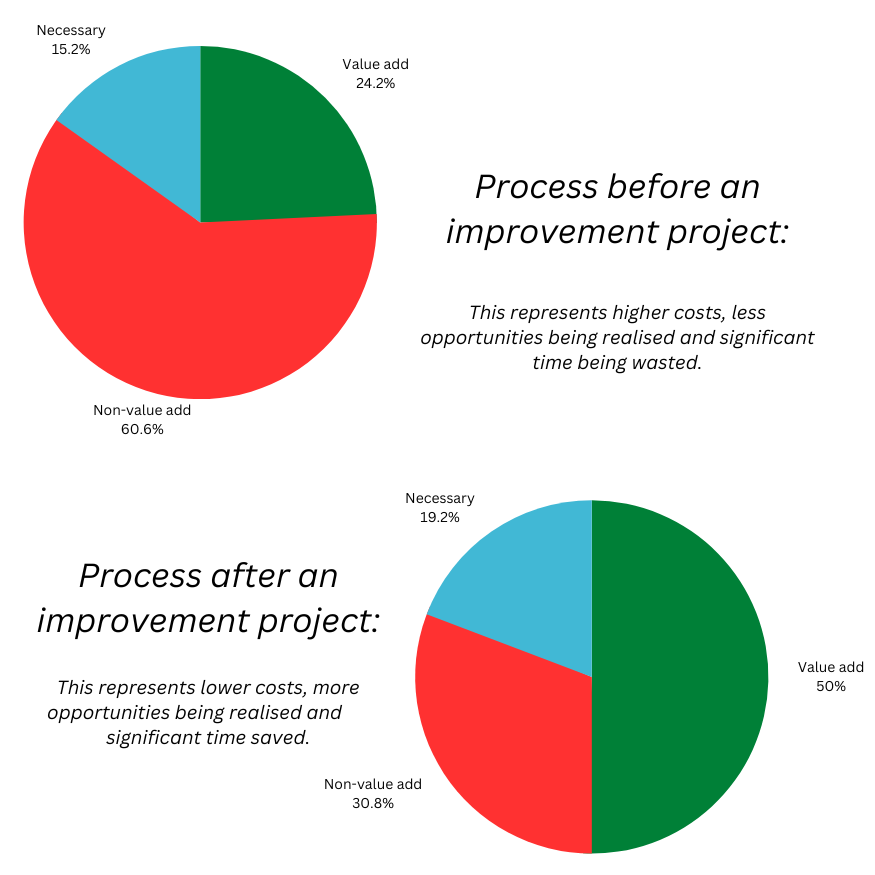

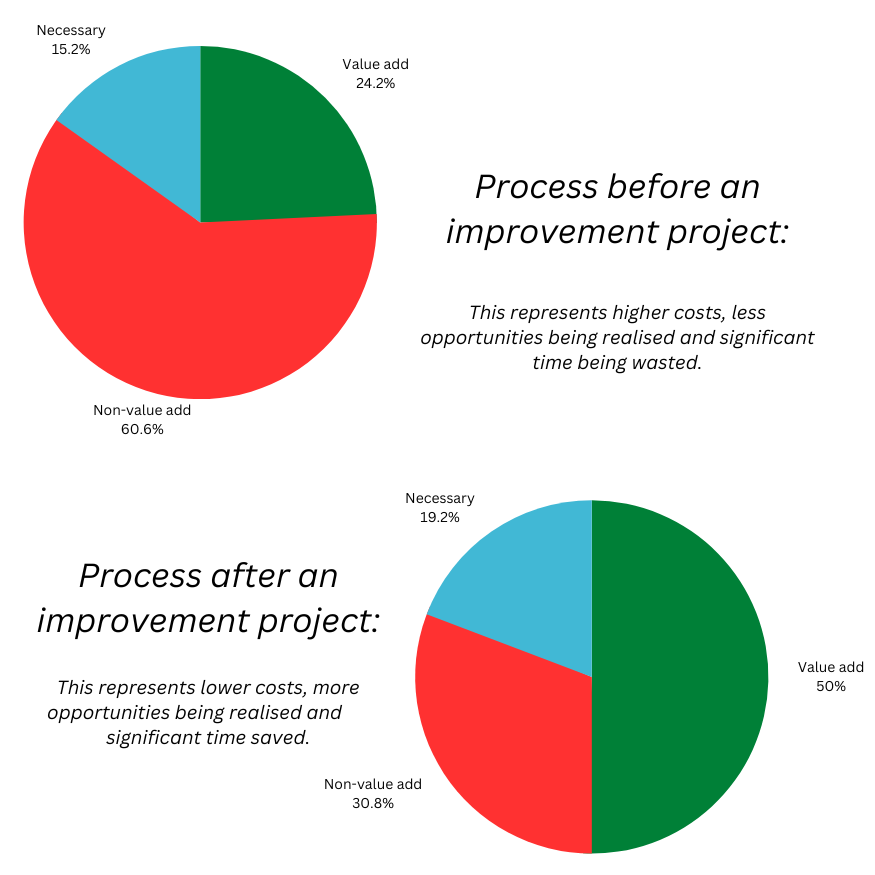

Value add

One of the key aspects of process improvement is to find and increase value in your process. This is done by finding and increasing the number of value-adding steps in your process. For context, value add can be defined as a step or activity that adds value to the process or final product, and is something a customer would be willing to pay/be charged for.

Process improvement seeks to identify where these steps are in a process, sure them up with good controls to ensure they remain value-adding and find a way to embed more value-adding activities into your process. This increases the overall value of the process, makes employees happier that their work is adding value to the wider organisation and increases the likelihood of more profit and a great ability to charge more as there is so much value provided.

Generic examples of value-adding activities would include:

- Development of the product

- Shipping and packaging of the product

- Improving the quality of a service or additional items/modules.

Non-value add

As we have value-adding activities, we of course have to have the opposite, those activities which do not add value to a process. These are referred to as non-value-adding activities. For context, non-value add can be defined as: a step or activity that does not add value to the process or final product, and is something a customer would not be willing to pay/be charged for.

In process improvement, these steps or activities would be deemed wasteful and unnecessary, and therefore the act of process improvement would be to reduce or remove as many of these steps as possible. There will always be times when processes may include steps that do not add value, but are needed to bridge the gap between two steps or two sections of a process. However, within process improvement, wherever you find steps which do not add value to the process, the aim is to remove them or find alternative ways to achieve the same outcome.

Generic examples of non-value-adding activities would include the moving of raw materials, the sending of data and information, building internal reports, peer review and checking.

Non-value add but necessary

There is also a 3rd type of step or activity from a value perspective, and that is those steps or activities that do not add any value, but are necessary or required steps. These are referred to as steps which are non-value-adding activities but are necessary. For content, non-value adding but necessary can be defined as: a step or activity which does not add value to the process, but is necessary to ensure the process can run and deliver its final output as anticipated.

In process improvement, these steps or activities are acknowledged but are not the focus of the work that needs to be done. Where the impact of these steps can be reduced, the time taken to complete them lessened and their numbers shrunk (through things like amalgamation). If, for any reason, you seek to change or indeed remove them, you would need to conduct a full risk assessment to ensure that doing so does not lead to big issues in terms of the performance of the process or governance / legal issues. Indeed, when we find non-value-adding but necessary process steps, these are often related to something legal or something regarding governance.

Generic examples of non-value-adding but necessary activities would include:

- Sign-off and approvals by legal or senior leaders accountable for the outputs

- Tax or compliance

- Providing personal information for medical or application purposes

Related: Understanding Value-Added and Non-Value-Added Activities

Types of Process in Process Improvement

When working through your process improvement initiative, your process in question will go through a series of iterations to get to that final, future state. As you do this, you will need to map out your process in a process mapping style, such as a swim lane map or flowchart. To do this, there are 3 stages you will need to map to get you from where you are today, to where you want to be tomorrow. Let’s explore these.

As-is process

When you first look to improve or reform a process, you need to map out (or analyse one if already created) the process as it currently stands. This is what we mean when we refer to something being “as-is” – how does the process run currently, as of today? When mapping out your as-is process or conducting your analysis, you need to map the process as you actually complete the process, not what you think people want to see, or indeed best practice. This can often occur when someone is asked to map out their process – they map out what they think others want to see. This misses a huge trick.

When mapping out your as-is process, ensure your map includes the following: All handoffs, bottlenecks, rework loops, involved departments, activities. If you want to make your map more advanced, you can include issues, problems, areas which create errors, times taken, cost of activities etc. The aim of mapping out your as-is process is so you can now make informed, insightful decisions based on fact. That is why it is so important you map out the actual process, as-is.

To-be process

The to-be process is the way in which you want your process to be delivered in the future. This is the ideal process, the process that can deliver your products and service error, issue and waste-free. When we seek to map out our to-be process, we want to map it with no restrictions, this is our perfect state, no holes barred, perfect delivery. With this, some blue sky thinking is required, some ambition and imagination.

When mapping out your to-be process, you need to remember the aim of the process improvement work you are doing. If you are seeking to reduce waste and increase the effectiveness of your process, you need to ensure you remove all unnecessary handoffs, rework loops, bottlenecks and non-value-adding activities. You need to reduce the number of departments involved, have better systems and technology in place and see the time taken to complete the process reduce, as much as possible. That is why, at this stage, you need to be ambitious and think – “if we could deliver the most effective, efficient and productive process possible, what would this look like?” Even if you do not end up getting to that process as your final, delivered process, it is a really good goal to keep you ambitious and focused.

Realised process

Sometimes referred to as realised process, delivered process or actual process, when it comes to this stage, here we are mapping out the process as it actually will be. The reason for the previous two steps and why we do not just jump to the realised state is two fold: 1) You need to understand exactly what the current situation is so you can effectively identify what steps need to be removed, where there is risk and what improvements could be made and 2) so you can map the ideal state to set real ambition into your team, so even if you can’t achieve this state, you will endeavour to get there by any means possible.

To map out your realised process, you would have first, conducted a gap analysis. This gap analysis is conducted to identify what gap exists between where you are today, and where you want to be tomorrow. It won’t be as simple as just saying – “we want to be here, so we are”. There is a lot more work involved. During the gap analysis, you will establish which process steps can be removed or reformed, and which ones cannot. You will test the future state process to see if the product or service output is delivered as expected, in the time expected and with the level of quality you expect. Through this testing, you will be able to identify where there are gaps and challenges, address them, and establish what you are actually able to achieve.

At the end of this effort will be your actual realised process, the process you are able to deliver. It will often be the case that this looks different to the process you mapped at the to-be state, as realism has set in that certain steps/activities simply cannot be removed or reformed. Decisions may have been made which means there is no budget for certain technologies that would have removed many steps, and therefore they will remain or you need to approach them in a different way. Regardless of all of this, at the end of the realised process step, you will have a process which can deliver your products and services quicker, more effectively and with increased quality.

Read: How to run a Process Improvement Workshop

Join our Process Improvement Certification Program

The process to deliver process improvement

To actually deliver processes which are improved on their original state is not as simple as mapping and changing. There will often be a process behind this to ensure you have thought through every step, and every eventuality and deliver the right reforms and improvements for that particular process. Let’s explore this approach.

Also read: What are the 5 key elements of process improvement?

Identify the process

The first activity you need to conduct is to identify that a process is in need of improvement. As we mentioned before, there will often be a trigger to indicate a change is required. Here, you need to acknowledge that trigger, identify which process this is referring to and clearly define this process. Many processes interlink with other processes, so try and define the scope of your process clearly here.

To do this, you can create a grid to highlight the important metrics around the process and see how they are ranking against what you would expect, and what you would want from a future state-reformed process. These metrics could include their current performance regarding SLAs and KPIs, customer and employee satisfaction, errors, and time taken to complete, to name but a few. It will depend on what is important for you and your organization.

Map the as-is process

As discussed earlier, you need to map out the process as it stands today. This effort will involve engaging with the SMEs of the process (as they can help you map the realities of the process), communicating effectively with all involved so they are aware of what needs doing and why you are conducting this work and then getting into a workshop and map the process. As you do this, remember to have in-depth conversations, asking questions about issues and opportunities faced.

Identify the value and non-value-adding steps

Once the process is mapped, you can work with your team to identify which steps in the process are adding value, and which are not. To conduct this exercise, you can colour code the steps in RAG format – red for steps which do not add value, green for steps which do add value and amber for those steps which do not add value but are required.

This is a powerful exercise to do with your team, as you can all stand back and see just how much waste is in the process, and how many opportunities to increase the value of the process and their work there is. This effort will help you to get buy-in from the wider team to continue on with this work because once everyone graphically sees the opportunities in front of them, they will be more motivated to continue the work.

Map the to-be process

Now you can see the extent of waste and opportunity within your process, you can effectively design your future state-to-be process. This can involve the simple removal of all of those steps which have been deemed non-value-adding steps (anything in red), the attempted reform at anything deemed non-value add but necessary (anything in amber) and the strengthening and potential increase of those steps identified as value-adding steps (anything in green).

When you conduct this activity, you will need to ensure the process can, in the to-be state, run from the starting point to the ending point without any issues.

Gap analysis

Armed with your as-is and to-be process maps, you can now conduct your gap analysis. At this stage, we can revisit all of those process steps and activities that we removed from our as-is process map to try and understand if we can actually remove all of these process steps, uninterrupted. The gap analysis here is to assist you in avoiding risk, specifically, the risk of removing steps from the process and something falling down later down the line. (You would be shocked to know just how many companies remove steps from their processes without testing whether or not this is actually feasible, and then experiencing big problems at a later date. Do not fall into this trap – conduct your gap analysis).

At this stage you will play around with your maps, testing each step removed and any new steps added in to see if the new steps continue to guarantee the success of the process, they achieve what they are built to achieve and that the steps that have been removed can successfully remain removed from the process.

Map the realised process

This step should be quite straightforward, given the majority of the process would have been built during the gap analysis stage. At the end of that stage, you will often see the final process. At this stage, you need to create the final map, as you want it to be shared with wider stakeholders. Any evidence of the gap analysis, any colouring (RAG) and commentary should be removed. You can at this stage add in any control measures you think may be needed to keep the process in check – just be mindful you do not add in wasteful, non-value-adding steps.

Test the new process

Now you have your new process mapped and ready to go, you can test it. This can be relatively straightforward, depending on what you did during the gap analysis stage. If you stress-tested steps at that stage, you should be in a better position now to trust the steps. However, you should still test the new process. This test can come in the form of using dummy data and dummy runs to test or parallel running the new process alongside the as-is process, testing the process with live data and scenarios. Either testing approach can be highly effective at ensuring the process works.

When testing, remember to be very clear on what you want the outcome of the new process to be. What products and services should be coming out of the process? What level of quality are you expecting the product and services to now be in compared to before? How much quicker do you want the process to run compared to before? What is your tolerance level for errors and issues? Set your parameters clearly and test against these.

Provide wider updates

The final step of a process improvement is one that is often overlooked – to update the wider business on the changes made. It is important to remember that the process changes will not necessarily just impact the immediate team, and indeed there could be a ripple effect across the wider business. Make sure everyone who needs to be updated has been, with a breakdown of the changes and the new process map.

Also read: 10 Pioneering Process improvement tools to optimize business performance

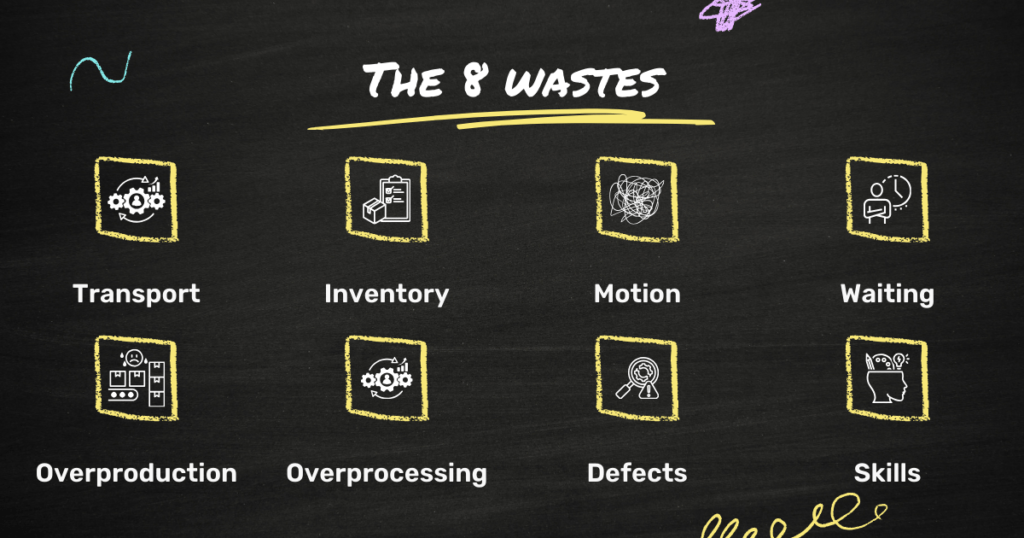

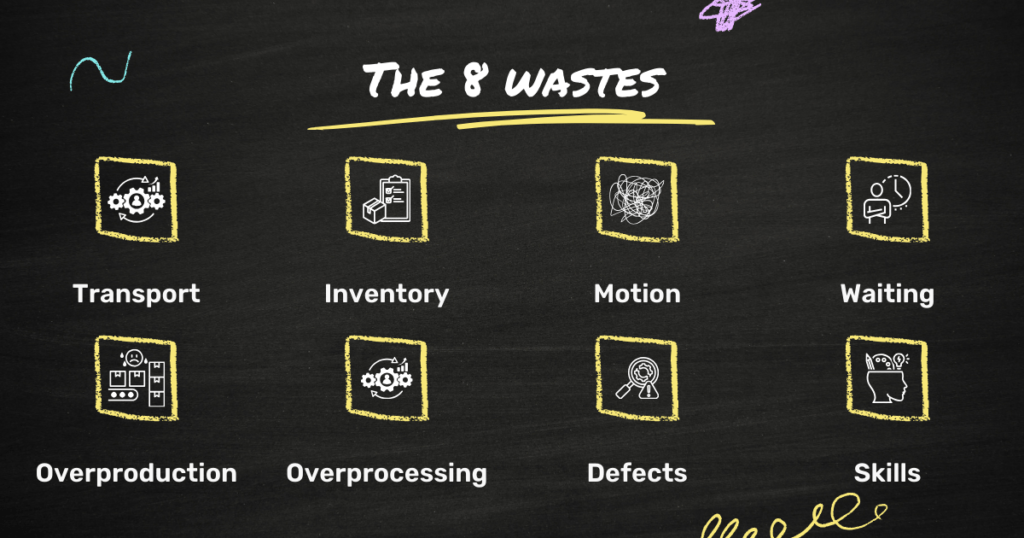

The 8 wastes

When running through your processes and identifying waste, it can often be helpful to identify what type of waste you are dealing with or are searching for. This is because, sometimes, waste is not as obvious as you may think, and therefore you need to know what you are searching for. With that in mind, there is an approach to waste known as the 8 wastes which people who deploy process improvement often follow. Let’s explore what these 8 wastes are.

Transport

Transport waste can be generated by the moving of things from one location to another. It can be generated by the location of resources being vastly spread out, geographically and lead to huge amounts of time waste being built into a process – time wasted waiting.

Examples of transport waste include handoffs between departments, sending and resending emails or information and moving goods from warehouse to warehouse.

The causes can include poor office/warehouse layout, unnecessary steps within a process or having too many sites to operate your business from.

Solutions of transport waste can include simplifying processes by reducing handoffs, prioritising what needs to be sent and to whom and having centres of excellence from where all operations run.

Inventory

Waste in inventory occurs when more products or services are stored or created than the customer has asked for. This can lead to a backlog of products and services that then need to be cleared through.

Examples of this type of waste include stockpiling of supplies, often just in case, a backlog of data waiting to be entered or the storing of information for longer than is required.

Causes could include poor monitoring systems, unreliable suppliers and misunderstood customer needs.

Solutions could revolve around providing a greater focus on the voice of the customer, a Kanban system for workflow to be introduced and a review of the suppliers.

Motion

Motion waste refers to any action that does not add value to the product, service or process. This action could be conducted by a human or a system, but it is something which does not positively impact the final output. This type of waste often occurs when we see something “repetitive” happening.

Examples of this type of waste include repetitive keystrokes (manual intervention), walking between equipment in the office and switching between applications on the computer.

Causes of motion waste can include poor office/workstation layout, poor process design (therefore requires manual steps) and congestion on equipment.

To solve for this waste, you could rearrange layouts to reduce the need to move, ensure enough equipment is available for all and resign processes to reduce the manual and repetitive steps.

Waiting

Waiting occurs whenever work or a process has to stop. In this instance, the process flow is disrupted by something which needs addressing, fixing or simply waiting for. The most common type of waiting waste is when you have to wait for someone within the process to complete their work before you can resume yours.

Examples of this type of waste include waiting for sign-off from another department, waiting for a part to be delivered to the site or waiting for a 3rd party provider to send over their data.

Causes of this type of waste can include work absences, poor communication and unbalanced workloads.

To help address this type of waste, you can ensure each worker has a delegate, implement tighter SLAs around when sign-offs are required and review the spread of workload across the team, ensuring it is balanced and fair and there is no risk of a backlog.

Overproduction

Overproduction occurs when workers produce more and more data/good, often when there is no real demand from the customer or the market for this. It can be the case that no orders have been placed for these products or services, but the provider is creating them “just in case” the demand does come. Organizations that create products and services “just in case” are often plagued with this type of waste.

Examples of overproduction would include too much data being produced, additional unread reports being produced and the manual storage of digital documents.

Causes of this type of waste include producing things “just in case” demand comes in, not knowing your customer requirements as clearly as you should or changes to your process not being communicated out.

Solutions for this waste could include creating an audit report to reduce the volume of products being produced in line with demand, developing a more effective way to understand customer needs and producing only the required amount of data, no more.

Overprocessing

Overprocessing waste occurs when we have the creation of multiple versions of the same task. This can lead to the production of multiple versions of the same product or the processing of something additional for no purpose. Rework loops are most commonly associated with this type of waste, something which plagues many processes across all organizations.

Examples of this type of waste include excessive reports being created, the same process having to be run time and time again as something has gone wrong (rework loop) or needing multiple signatures.

Causes of this type of waste can include poor communication, human error and the misunderstanding of customer needs, often because the method by which customer needs are established is wrong or not fit for purpose.

Solutions for this type of waste can include eliminating unnecessary sign-offs, vetting all requests for reports to ensure they do not already exist and giving each process an owner to avoid any confusion.

Defects

Defects refer to mistakes that are made when running a process to deliver a service or product. These defects, also referred to as errors, cause problems for your processes, making you spend more time completing the process, fixing the issues that arise from the errors and dealing with the fallout.

Examples of defects can include missed deadlines, missing or incorrect data and the wrong file being uploaded to a system.

Causes of such defects can include documentation being out of date (including work instructions), customer needs being miscommunicated and there being a lack of controls, and checks and balances in the process.

To solve for this type of waste, you can ensure all documentation is up to date, quality check data ahead of the upload into a system and could root cause every defect that occurs to identify the right controls for the future.

Skills

Skills waste is often related to the non-utilisation of skills in your organization. There can be a wealth of skills individuals in a business harbour, but due to the nature of their roles or the understanding from management of the skills they have, these skills are not utilised in the way they should be. Not utilising such skills can be a significant waste for an organization.

Examples of skills waste include assigning staff to the wrong tasks, not bringing in the Continuous Improvement Team to improve processes when required and not knowing the extent of the skills made up in the team.

Causes of this type of waste include poor communication of the skillset available and that which is required, poor management (not seeing what skills their team have) and a lack of teamwork.

Solutions for this type of waste can include conducting a skills matrix and keeping the document live, better-defining roles and responsibilities within projects and management being trained to better recognise skillsets and upskill their teams.

Also Read: A Comprehensive Guide to Process Improvement Methodologies

Conclusion

Process improvement, as I hope you can now see, is a powerful tool that can deliver fantastic results. Whilst the end result, an improved process, will always be the same aim, how we get there will be different depending on the process in question, the team running the process and the needs of the business. With process improvement, it is always important to remember the ripple effect it can have on an organisation. Deliver it well, and process improvement can set your organisation up for big success over the long term.