Table of Contents

Introduction

Hello and welcome! I’m Robert Chapman, a Six Sigma Black Belt with over a decade of experience in enhancing business processes. This blog is dedicated to sharing insights and practical knowledge on Business Process Automation (BPA)—a transformative approach that can streamline your operations and unlock new levels of efficiency.

The aim here is simple: to provide you with a clear, actionable understanding of BPA. Whether you’re looking to reduce costs, improve accuracy, or gain a competitive edge, this blog will guide you through the essentials of automating business processes, from concept to execution.

This blog is crafted for anyone involved in business operations, from project managers and process engineers to C-suite executives and entrepreneurs. If you’re seeking to drive improvement within your organization, you’ll find valuable resources and strategies here to help you succeed.

Understanding Business Process Automation

What is Automation?

Automation, in its simplest form, is the technology-enabled execution of tasks without human intervention. It’s the art of making processes run on their own, reliably and with precision, to enhance efficiency and productivity.

Definition & Significance

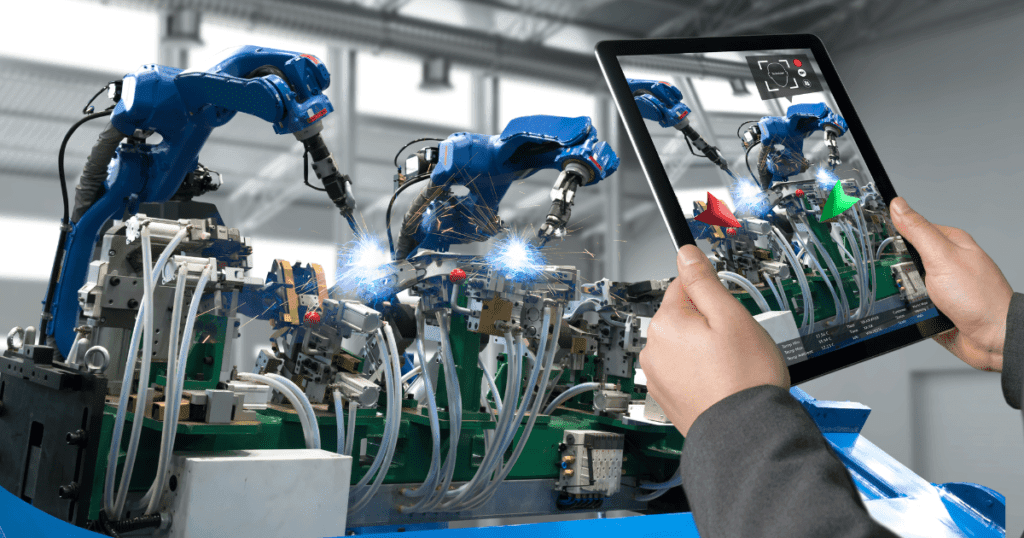

The term ‘automation’ comes from the Greek word ‘automatos’, meaning ‘acting of itself’. Historically, it referred to mechanical devices that mimicked human actions. Today, it encompasses a broad range of technologies, including robotics, artificial intelligence, and software applications, all designed to perform tasks that would otherwise require human effort. The significance of automation lies in its ability to transform industries, boost efficiency, and create opportunities for innovation and growth.

Origin of Business Process Automation

The concept of BPA is deeply rooted in the history of automation itself. While the term ‘business process’ is relatively modern, the practice of automating tasks for efficiency dates back to ancient civilizations. The Greeks and Romans used complex machines to automate public services like water clocks and temple doors. The Industrial Revolution brought about a significant leap in automation, with the introduction of machinery to perform labour-intensive tasks. This paved the way for the development of BPA as we know it today, where technology is used to streamline and optimize business processes for maximum efficiency and effectiveness.

Evolution of Automation in Business

The journey of automation in business has been evolutionary, beginning with simple mechanical aids and evolving into sophisticated software that can learn and adapt. The origin of Business Process Automation (BPA) can be traced back to the early days of industrialization when mechanical systems were used to enhance production efficiency. Over time, these systems became more complex, integrating with computing technology to form the foundation of modern BPA.

The evolution of BPA has been marked by several key developments:

- Enterprise Applications (1980s to Present): The rise of enterprise systems in the 1980s marked the first significant phase, focusing on specific business functions like accounting and human resources management.

- Business Process Management (Late 1990s to Present): The widespread adoption of BPM systems improved operational efficiency and integration capabilities.

- Digital Process Automation (2010 to Present): The latest phase, characterized by the use of digital technologies to automate complex business processes and enhance customer experiences.

What is a Process?

A process is a collection of interrelated tasks that, when performed in sequence, achieve a specific goal. It’s the blueprint that guides the flow of work from start to finish, ensuring consistency and efficiency.

- Process Fundamentals At the heart of every process are the fundamental elements that define its structure and purpose:

- Inputs: The resources, information, or materials required to start the process.

- Activities: The tasks or operations that transform inputs into outputs.

- Outputs: The final product or service that results from the process.

- Controls: The policies, rules, and guidelines that govern the process.

- Feedback: The information that is used to monitor and improve the process performance.

- Types of Business Processes Business processes can be categorized into three main types, each serving a distinct function within the organization:

- Core Processes: These are the central activities that deliver value directly to customers and are essential for the business’s primary objectives, such as sales, marketing, and customer service.

- Support Processes: These processes provide necessary support to core processes and include functions like human resources, accounting, and IT services.

- Management Processes: These are the strategic and administrative processes that guide the operation and direction of the company, including planning, governance, and performance management.

Understanding these fundamentals and types of business processes is crucial for any organization looking to streamline operations and achieve strategic goals.

What is Process Automation?

Process Automation is the application of technology to automate complex business processes. It involves using software applications and tools to perform tasks that would typically require manual effort, such as data entry, calculations, or even decision-making.

- Distinguishing Automation & Process Automation While ‘automation’ can refer to any use of technology to perform tasks without human intervention, ‘process automation’ is more specific. It focuses on automating the workflows and operations that make up business processes. The key difference lies in the complexity and the end goal: process automation aims to streamline entire business processes, not just individual tasks, leading to greater efficiency and consistency across an organization.

- Real-World Examples of Process Automation The real-world impact of process automation is vast and varied. Here are a few examples:

- Approval Requests: Automating approval workflows can significantly reduce processing time. For instance, Audi Japan KK’s finance department automated their approval requests, leading to a 75% reduction in processing time.

- Vendor Management: Deutsche Post DHL Group automated their vendor selection process, which is accessed by 320,000 users worldwide, providing complete visibility and a standardized workflow.

- Supplier Onboarding: Adidas streamlined their supplier onboarding process across multiple departments, reducing the time to market by two-thirds.

- Claims Processing: Insurer BNP Paribas Cardif Japan automated their claims process, which allowed them to shorten the delivery of new product releases from four weeks to just ten minutes.

These examples demonstrate how process automation can transform various aspects of a business, leading to significant time savings, cost reductions, and efficiency improvements.

Purpose & Benefits of Process Automation

The implementation of Process Automation within an organization serves a multifaceted purpose, each contributing to the overarching goal of enhancing business performance.

- Efficiency & Accuracy Process Automation is instrumental in refining the efficiency and accuracy of business operations. By automating routine and repetitive tasks, companies can significantly reduce the time and effort required to complete them. This leads to streamlined workflows, where tasks are executed consistently and precisely, minimizing the potential for human error and ensuring a higher standard of quality.

- Cost Reduction & ROI One of the most compelling advantages of Process Automation is its impact on cost reduction and Return on Investment (ROI). By minimizing the need for manual intervention, organizations can lower operational costs and reallocate resources to more strategic areas. This not only reduces expenses but also enhances the value generated from investments in automation technologies. In many cases, the initial investment in automation can be recouped within a relatively short period, leading to long-term financial benefits.

- Competitive Advantage In today’s dynamic business world, it’s essential to hold onto your competitive edge. Process Automation provides companies with the agility to respond quickly to market changes and customer demands. It enables businesses to offer faster services, improve customer experiences, and innovate more rapidly. By leveraging automation, companies can stay ahead of the competition, offering superior products and services that are delivered more efficiently and effectively.

The benefits of Process Automation are clear and impactful, driving not just operational improvements but also strategic advantages that can position a company for future success.

Initiating Process Automation

Defining a “Ripe” Process for Automation

When it comes to automation, not every process is equally suitable. A “ripe” process for automation is one that stands to gain the most from the introduction of technology, leading to significant improvements in performance and outcomes.

- Characteristics of an Automatable Process An ideal process for automation typically has the following characteristics:

- High Frequency: The process is performed regularly, making automation a worthwhile investment.

- Rule-Based: It follows a clear set of rules or logic, allowing for consistent automated decision-making.

- Standardized Inputs: The process uses uniform data formats or inputs, which are essential for seamless automation.

- Time-Consuming: It involves tasks that are tedious and time-intensive, where automation can free up valuable human resources.

- Error-Prone: The process is susceptible to human error, and automation can significantly reduce these errors.

- Digital Readiness: It utilizes digitally available data, which is necessary for software-based automation solutions.

- Selecting the Right Process: A Step-by-Step Guide To select the right process for automation, follow this genuine and accurate guideline:

- Assess Your Current Processes: Begin by mapping out your business processes and identifying areas where inefficiencies are most evident.

- Define Your Objectives: Clearly articulate what you hope to achieve through automation, such as cost savings, time reductions, or quality improvements.

- Evaluate Process Complexity: Consider the complexity of the process and whether it can be broken down into simpler, automatable steps.

- Consider the Impact: Look at the potential impact of automation on the process, including benefits to employees, customers, and other stakeholders.

- Check Technical Feasibility: Ensure that the technology required to automate the process is available and aligns with your IT infrastructure.

- Calculate the ROI: Estimate the return on investment by comparing the costs of automation against the expected benefits.

- Prioritize and Select: Based on the assessment, prioritize the processes that are most ripe for automation and select the one that offers the best balance of benefits, feasibility, and strategic alignment.

By carefully evaluating and selecting the right processes for automation, businesses can ensure that their automation initiatives are successful and deliver tangible benefits.

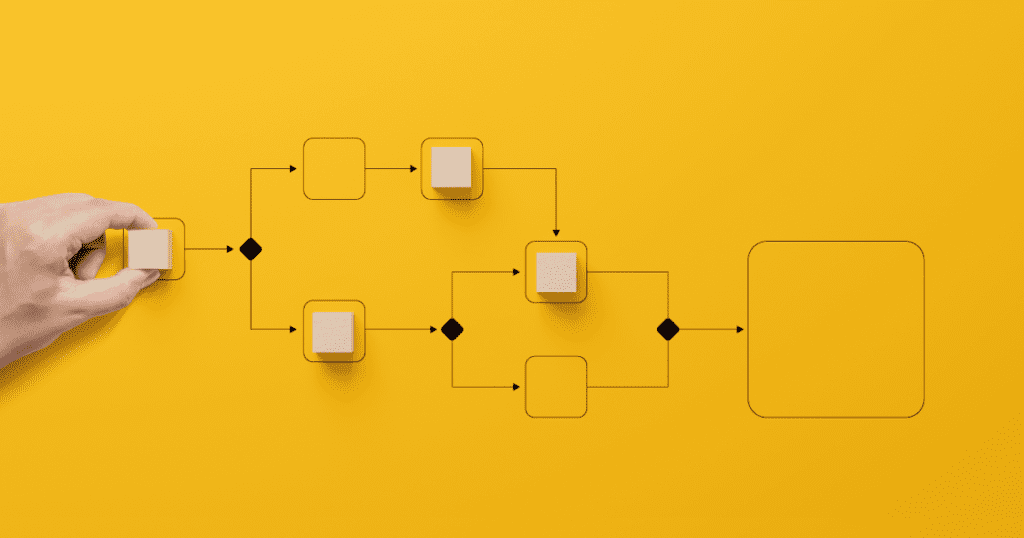

Mapping the Process

Mapping is a critical step in process automation. It provides a visual representation of the workflow, making it easier to understand and analyze. Let’s explore the tools and techniques used for process mapping and see a demonstration of how it’s done.

- Tools & Techniques for Process Mapping A variety of tools and techniques are available to assist in process mapping, each with its unique strengths:

- Gantt Charts: Useful for planning and scheduling complex processes.

- UML Diagrams: Offer a standardized way to visualize system designs.

- Business Process Modeling Notation (BPMN): A graphical representation that details business processes in a workflow.

- Flowcharts: Provide a simple and clear way to represent the steps in a process.

- Data Flow Diagrams: Focus on the flow of data within a process.

- Value Stream Mapping (VSM): Helps identify waste and streamline production processes.

- IPO (Input-Process-Output) Model: Clarifies the inputs, outputs, and required processing tasks.

- A Demonstration of Process Mapping To demonstrate process mapping, let’s consider a simple example: an employee onboarding process.

- Identify the Process: Begin by defining the start and end points. For onboarding, the process starts when a candidate accepts the job offer and ends when the employee is fully integrated into the company.

- List the Activities: Document all tasks involved in the onboarding process, such as signing contracts, setting up workstations, and training sessions.

- Assign Roles: Determine who is responsible for each task, ensuring accountability and clarity.

- Create the Process Map: Using a flowchart, map out each step of the process. Indicate the sequence of tasks, decision points, and the flow of information.

- Review and Optimize: Analyze the process map for any inefficiencies or bottlenecks and make necessary improvements.

Download all the necessary templates for your project from our Free template collection

This demonstration shows how process mapping can provide a clear, visual understanding of a process, which is essential for successful automation.

Analyzing the Process

Once a process has been mapped, the next step is to analyze it to identify areas for improvement. This involves a critical examination of each step to determine its efficiency and effectiveness.

- Critical Analysis Techniques To thoroughly analyze a business process, several techniques can be employed:

- Value Stream Mapping: Identifies waste and helps visualize the flow of materials and information.

- Root Cause Analysis: Aims to discover the underlying causes of problems within a process.

- Gap Analysis: Compares the current state of a process with the desired state to identify areas for improvement.

- Pareto Analysis: Uses the 80/20 rule to focus on the most significant issues that will yield the most substantial results.

- Six Sigma Methodologies: Utilize statistical analysis to measure and improve a company’s operational performance, practices, and systems.

- Key Questions to Drive Process Improvement When analyzing a process for improvement, consider asking the following questions:

- Does this process align with our strategic objectives?: Ensuring that the process contributes to the broader goals of the organization.

- What are the bottlenecks?: Identifying where delays or obstacles occur.

- Which steps add value?: Distinguishing between value-adding and non-value-adding activities.

- How can we eliminate waste?: Looking for ways to remove unnecessary steps.

- What are the risks associated with this process?: Assessing potential issues and their impact.

- How can technology improve this process?: Considering the role of automation or other technological solutions.

- What feedback have we received about this process?: Gather insights from stakeholders and those involved in the process.

By applying these techniques and asking these critical questions, you can gain a deeper understanding of the process and identify opportunities for significant improvements.

Preparing the Process for Automation

Before diving into the technicalities of automation, it’s crucial to lay the groundwork. This preparation involves two key components: documentation and standardization, and stakeholder engagement and change management.

- Documentation & Standardization Documentation is the cornerstone of process automation. It involves creating detailed records of the current process, including each step, decision point, and outcome. This documentation serves as the blueprint for automation and ensures that nothing is overlooked in the transition. Standardization goes hand-in-hand with documentation. It’s about establishing a consistent way of performing tasks across the organization. By standardizing processes, you ensure that they are carried out uniformly, which is essential for successful automation. This includes setting specific standards that workers must adhere to, such as handling correspondence, filing documents, and addressing complaints.

- Stakeholder Engagement & Change Management Stakeholder engagement is about involving those who will be affected by the automation in the planning and implementation process. This includes employees, management, and possibly customers. Effective engagement helps to ensure buy-in and can greatly reduce resistance to change. Change management is the framework used to guide and support the organization through the transition to automation. It involves planning, oversight, and support to ensure that the change is implemented smoothly and effectively. Key activities include communication, training, and providing support to employees and stakeholders affected by the change.

By thoroughly preparing in these areas, you can set the stage for a successful transition to process automation, ensuring that the organization is ready to embrace the new automated workflows.

Documentation & Planning

Process Definition Document (PDD)

The PDD is a foundational document in process automation, serving as a detailed guide for the development and implementation of automated workflows.

- Purpose & Components of a PDD The purpose of a PDD is to provide a thorough description of the current process (As-Is) and outline the envisioned automated process (To-Be). It acts as a communication tool between stakeholders and the development team, ensuring that all parties have a clear understanding of the process and the automation objectives. A comprehensive PDD typically includes the following components:

- Introduction: Explains the purpose of the document and the objectives of the automation project.

- As-Is Process Description: Details the current process steps, including the time spent on each step and the applications used.

- To-Be Process Description: Describes the future state of the process after automation, including any changes or improvements made.

- Process Maps: Visual representations of both the As-Is and To-Be processes.

- Business Rules: Defines the logic and decision-making criteria within the process.

- Exceptions Handling: Outlines how the automated process will handle deviations and unexpected scenarios.

- Roles and Responsibilities: Specifies who is responsible for each part of the process.

- Reporting: Identifies who will receive reports on the process’s performance and how exceptions will be communicated.

- Creating a Comprehensive PDD: A Walkthrough Creating a PDD involves several steps to ensure that it captures all necessary details for successful automation:

- Gather Information: Work with subject matter experts (SMEs) to collect detailed information about the current process.

- Map the As-Is Process: Document the existing process steps, including inputs, outputs, and decision points.

- Identify Improvements: Analyze the As-Is process to find opportunities for efficiency gains and error reduction.

- Design the To-Be Process: Develop a streamlined process flow that incorporates the identified improvements and automation capabilities.

- Define Business Rules and Exceptions: Clearly articulate the rules that govern the process and how exceptions will be managed.

- Create Visual Process Maps: Use flowcharts or BPMN diagrams to visually represent both the As-Is and To-Be processes.

- Review and Refine: Collaborate with stakeholders to review the PDD and make refinements as needed.

- Finalize and Approve: Obtain approval from all relevant parties to ensure the PDD accurately reflects the intended automation solution.

By following these steps, you can create a PDD that serves as a clear and effective roadmap for automating a business process.

Enrol in the Business Process Automation Certification Course. Gain advanced insight, case study, template use and certification.

Solution Definition Document (SDD)

The SDD is a pivotal document in the process automation lifecycle, detailing the technical specifications and the design of the solution that will be implemented.

From PDD to SDD: Bridging the Gap Transitioning from a Process Definition Document (PDD) to a Solution Definition Document (SDD) involves moving from the ‘what’ to the ‘how’. The PDD outlines the current process and the desired outcomes, while the SDD describes how those outcomes will be achieved through automation. This transition is crucial as it turns the theoretical framework provided by the PDD into a practical, actionable plan.

SDD Structure & Importance The structure of an SDD typically includes:

- Introduction: Describes the purpose of the document and the scope of the solution.

- Detailed Design: Provides a comprehensive description of the proposed solution, including system architecture, data models, and workflows.

- Technical Requirements: Lists the technical specifications required to implement the solution.

- Development and Deployment Plan: Outlines the steps for developing and deploying the automation solution.

- Testing Strategy: Details the approach for testing the solution to ensure it meets the required standards.

- Maintenance and Support: Describes the processes for maintaining and supporting the solution post-deployment.

The importance of an SDD lies in its role as a guiding document for the development team. It ensures that all technical aspects of the solution are clearly defined and understood before development begins. This helps in avoiding misunderstandings and ensures that the solution meets the business requirements as outlined in the PDD. An effective SDD is essential for the successful implementation of any automation project.

Execution & Monitoring

Development Phase

The development phase is where the planned automation solution comes to life. It’s a critical stage that requires a structured approach to ensure the successful implementation of process automation.

- Agile Methodology in Automation Agile methodology is particularly well-suited for automation projects due to its iterative nature and focus on collaboration and feedback. In an Agile environment, automation is developed in short, manageable iterations, allowing for continuous integration and testing of new features. This approach ensures that the automation solution evolves in response to changing requirements and can adapt to new challenges as they arise. Key principles of Agile in automation include:

- Iterative Development: Building the automation solution incrementally, allowing for regular assessment and adjustments.

- Collaboration: Working closely with stakeholders, including business analysts, developers, and end-users, to ensure the solution meets the needs of all parties.

- Feedback Loops: Regularly testing and seeking feedback on the automation to refine and improve its functionality.

- Flexibility: Being prepared to respond to changes in the process or business environment that may impact the automation solution.

- Development Best Practices Following best practices during the development phase is essential to create a robust and reliable automation solution. Some of these best practices include:

- Version Control: Using version control systems to manage changes to the automation scripts and configurations.

- Modular Design: Building automation in modular components to facilitate easier maintenance and scalability.

- Code Reviews: Conducting regular code reviews to ensure quality and consistency across the development team.

- Continuous Integration and Testing: Implementing continuous integration tools to automate the build and testing of the automation solution, ensuring that any changes do not break existing functionality.

- Documentation: Keeping comprehensive documentation of the development process, including code comments, to aid in future maintenance and updates.

By adhering to Agile principles and development best practices, the automation project can progress smoothly from concept to deployment, ensuring a solution that is both effective and sustainable.

User Acceptance Testing (UAT)

What is UAT & Why It Matters?

User Acceptance Testing, commonly known as UAT, is the final phase in the software development lifecycle before the product release. It involves real-world users testing the software to ensure it meets their needs and the business requirements that were initially set out. UAT is crucial because it validates that the software functions not just technically, but also from the user’s perspective. It’s the last line of defence to catch any issues that could affect the user’s experience and satisfaction.

Conducting Effective UAT: A Roadmap

To conduct effective UAT, follow this structured approach:

- Preparation: Before UAT begins, ensure that all previous testing phases are complete and that the software is as bug-free as possible.

- Define Criteria: Establish clear acceptance criteria that the software must meet to pass UAT. These criteria should be based on the business requirements and user needs.

- Select Testers: Choose a group of end-users who represent the software’s target audience. These individuals should have a strong understanding of the business processes that the software aims to support.

- Develop Test Cases: Create test cases that cover all the functionalities of the software. These should be based on real-world scenarios that the users will encounter.

- Conduct Testing: Allow the selected users to execute the test cases. They should document their findings, noting any discrepancies between expected and actual results.

- Gather Feedback: Collect and analyze the feedback from the users to identify any areas where the software does not meet the acceptance criteria.

- Iterate: Use the feedback to make necessary adjustments to the software. Repeat the testing process until the software meets the acceptance criteria.

- Sign-Off: Once the software passes UAT, obtain formal approval from the stakeholders to proceed with the release.

By following these steps, you can ensure that UAT is thorough and effective, leading to a software product that truly meets the needs of its users.

Production Roll-Out

Transitioning a process automation solution from the development phase to production is a critical step that requires careful planning and consideration.

- Transitioning to Production: Key Considerations When moving to production, several key factors must be taken into account to ensure a smooth transition:

- Testing: Ensure that the solution has been thoroughly tested in an environment that closely replicates the production setting.

- Documentation: Update all documentation to reflect any changes made during the development phase and ensure it is accessible to all relevant parties.

- Training: Provide comprehensive training to all users on the new system to ensure they are comfortable with the changes.

- Data Migration: If applicable, plan and execute the migration of data from the old system to the new one, ensuring data integrity and minimal downtime.

- Rollback Plan: Have a contingency plan in place in case issues arise during the transition that require reverting to the old system.

- Communication: Keep all stakeholders informed throughout the transition process to manage expectations and report progress.

- Monitoring & Support: Ensuring Smooth Operations Once the solution is live, ongoing monitoring and support are essential to maintain smooth operations:

- Proactive Monitoring: Implement monitoring tools to continuously check the system’s performance and identify potential issues before they become problems.

- Support Structure: Establish a clear support structure for users to report issues and receive help.

- Performance Metrics: Define and track performance metrics to measure the success of the automation solution and identify areas for improvement.

- Feedback Loop: Create a feedback loop with users to gather insights and suggestions for further enhancements.

- Maintenance Schedule: Set up a regular maintenance schedule to update the system, apply patches, and perform other necessary upkeep.

By addressing these considerations, you can ensure that the production roll-out of your process automation solution is successful and that operations continue to run smoothly post-deployment.

Maintenance & Control

The maintenance and control phase is vital to the long-term success of an automation solution. It involves ongoing activities to ensure the solution continues to operate effectively and adapts to any changes or improvements over time.

- Continuous Improvement in Automation Continuous improvement in automation is about regularly assessing and enhancing the automated processes to ensure they remain efficient and aligned with business goals. This involves:

- Monitoring Performance: Keeping track of the system’s performance and identifying areas for improvement.

- Gathering Feedback: Collecting input from users and stakeholders to understand how the automation impacts their work and where it can be improved.

- Implementing Changes: Making incremental changes to the automation based on the feedback and performance data.

- Using Agile Methodologies: Applying Agile principles such as sprint retrospectives to reflect on what’s working well and what could be better.

- Applying the PDCA Cycle: Utilizing the Plan-Do-Check-Act cycle to plan for change, implement it on a small scale, analyze the results, and act on the findings.

- Handling Exceptions & Updates Exception handling and managing updates are crucial for maintaining the integrity of the automation solution:

- Structured Error Handling: Establishing a framework for detecting and managing errors that may occur during the automation process.

- Exception Propagation: Ensuring that exceptions are reported to the appropriate level so they can be addressed effectively.

- Cleanup and Recovery: Creating procedures for cleaning up after errors and recovering the system to a stable state.

- Logging and Reporting: Keeping detailed logs of exceptions and errors, and reporting them to stakeholders for transparency and accountability.

- Unit Testing: Regularly testing individual components of the automation solution to ensure they function correctly after updates or changes.

By focusing on continuous improvement and effective exception handling, businesses can ensure their automation solutions remain robust, adaptable, and capable of delivering ongoing value.

Conclusion

As we wrap up this comprehensive journey through the intricacies of Business Process Automation (BPA), let’s take a moment to reflect on the key learnings and chart the path forward.

We’ve explored the essence of automation, delved into the specifics of process automation, and uncovered the significant benefits it brings to businesses. From understanding what constitutes a process to identifying ripe opportunities for automation, we’ve laid out a roadmap for successful implementation. We’ve also navigated through the critical stages of documentation, planning, execution, and monitoring, ensuring that each step is taken with precision and care.

I want to extend my heartfelt thanks to you, the reader, for embarking on this journey with me. Your engagement and willingness to learn are what drive the continuous improvement and innovation in the field of business improvement.

The journey doesn’t end here. As you move forward, I encourage you to apply the insights and strategies shared in this blog to your own business processes. Begin by identifying potential automation opportunities within your organization and use the guidelines provided to initiate your first project. Remember, the world of BPA is ever-evolving, and staying informed and adaptable is key to long-term success.

Thank you once again for your time and attention. Should you have any questions or require further assistance, please don’t hesitate to reach out. Here’s to your success in harnessing the power of process automation!