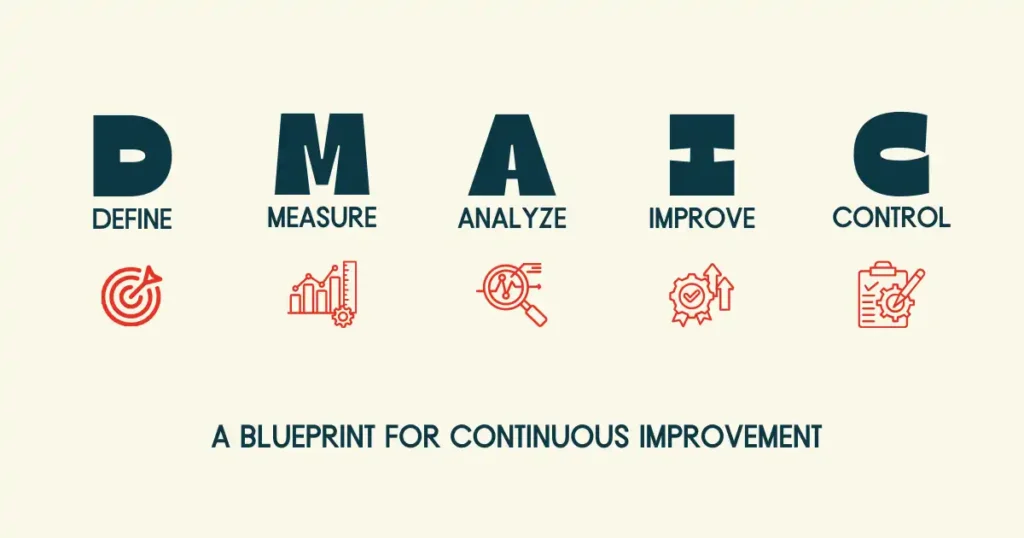

DMAIC: A Blueprint for Continuous Improvement

DMAIC – The Game-Changer for Business Excellence In today’s competitive business landscape, DMAIC (Define, Measure, Analyze, Improve, Control) emerges as a transformative methodology pivotal to the philosophy of Lean Six Sigma. Celebrated for revolutionizing processes at industry giants like Toyota, GE, and Motorola, DMAIC serves as a powerful tool for addressing inefficiencies, enhancing quality, and reducing costs. […]