Table of Contents

Introduction: Lean Thinking and Its Impact

In today’s dynamic business landscape, organizations strive for efficiency, agility, and sustainable growth. Lean Thinking emerges as a powerful approach that transcends industries, enabling companies to achieve these goals. So, what exactly is Lean Thinking, and why does it matter?

Defining Lean Thinking

At its core, Lean Thinking is a philosophy rooted in simplicity, waste reduction, and value creation. Originating from Toyota’s production system, it has since spread across manufacturing, services, healthcare, and beyond. Lean Thinking emphasizes doing more with less—maximizing value while minimizing waste.

Significance Across Industries

Lean Thinking isn’t confined to a single sector; it permeates various domains:

- Manufacturing: Lean principles optimize production lines, reduce inventory, and enhance quality.

- Healthcare: Hospitals apply Lean to streamline patient flow, reduce wait times, and improve patient outcomes.

- Service Industries: From banking to retail, Lean helps eliminate bottlenecks, enhance customer experiences, and boost efficiency.

Core Principles of Lean

- Continuous Improvement (Kaizen): Lean champions perpetual progress. Teams engage in small, incremental improvements daily. These cumulative gains lead to significant transformations over time.

- Respect for People: Lean recognizes that engaged, empowered employees drive success. It encourages collaboration, problem-solving, and shared ownership.

- Waste Reduction: Lean identifies and eliminates eight types of waste (Muda):

- Overproduction

- Waiting

- Transportation

- Overprocessing

- Inventory

- Motion

- Defects

- Underutilized talent

In this article, we’ll delve deeper into these principles, explore practical applications, and equip you with actionable insights. Let’s embark on our Lean journey together!

Foundations of Lean Thinking

Origins and Toyota’s Production System

Lean Thinking traces its roots back to post-World War II Japan, specifically within the Toyota Motor Corporation. Taiichi Ohno, an engineer at Toyota, played a pivotal role in shaping this revolutionary approach. Here’s how it all began:

Toyota Production System (TPS)

- In the 1950s, Toyota faced resource constraints, limited space, and fierce competition.

- Taiichi Ohno and Shigeo Shingo developed the Toyota Production System (TPS) as a response to these challenges.

- TPS aimed to achieve high-quality production with minimal waste, reduced lead times, and maximum efficiency.

Fundamental Pillars of Lean Thinking

1. Just-in-Time (JIT) Production

- What is JIT?

- JIT is the heartbeat of Lean Thinking.

- It revolves around producing goods or services precisely when needed—no sooner, no later.

- The goal? Minimize waste (such as excess inventory) while meeting customer demand.

- Key Principles of JIT:

- Pull System: Production is driven by customer demand signals (pull), not by pushing excess inventory.

- Takt Time: The rhythm at which products or services must be produced to match demand.

- Kanban: Visual cards or signals that regulate material flow and trigger production.

- Single-Minute Exchange of Die (SMED): Rapid changeovers to reduce downtime during production transitions.

2. Autonomation (Jidoka)

Business Process Automation Certification Course

- What is Autonomation?

- Autonomation (or Jidoka) combines automation with human intelligence.

- It empowers workers to detect defects or abnormalities and stop production immediately.

- Quality is built into the process, preventing defective products from reaching customers.

- Key Aspects of Autonomation:

- Andon System: Visual signals (often lights or displays) alerting operators to issues.

- Poka-Yoke: Foolproof mechanisms that prevent errors (e.g., car keys that can only fit one way).

- Respect for Workers: Trusting employees to make critical decisions and improve processes.

In our Lean journey, understanding these pillars will guide us toward effective process improvement. Next, we’ll explore Continuous Improvement (Kaizen).

Related: Business Process Automation (BPA): A Step-by-Step Guide for Efficiency and Growth

Continuous Improvement (Kaizen)

Understanding Kaizen

Kaizen—derived from the Japanese words “kai” (change) and “zen” (good)—represents a mindset of perpetual enhancement. Here’s what you need to know:

- Incremental Changes: Kaizen focuses on small, manageable adjustments rather than radical overhauls. These tweaks accumulate over time, leading to substantial progress.

- Everyday Kaizen: It’s not a one-time event; it’s a daily practice. Teams actively seek opportunities to improve processes, eliminate waste, and enhance quality.

- Employee Involvement: Kaizen thrives when everyone participates. Frontline workers, managers, and leaders collaborate to identify bottlenecks and implement solutions.

The Kaizen Process

- Identify Opportunities:

- Regularly assess processes, workflows, and tasks.

- Look for inefficiencies, delays, and areas where value isn’t maximized.

- Brainstorm Solutions:

- Gather cross-functional teams.

- Encourage open discussions and creative thinking.

- Generate ideas for improvement.

- Test and Implement:

- Pilot the proposed changes on a small scale.

- Measure the impact (e.g., reduced cycle time, improved quality).

- If successful, roll out the changes more broadly.

- Standardize and Sustain:

- Document the improved process.

- Train employees on the new way of working.

- Monitor and maintain the gains achieved.

Examples of Successful Kaizen Initiatives

- Manufacturing:

- Reducing Setup Time: A car manufacturer implemented SMED techniques to reduce changeover time between production runs. Result: Increased production capacity and flexibility.

- Line Balancing: Ensuring workstations have similar workloads, minimizing idle time and maximizing efficiency.

- Healthcare:

- Nurse Handoffs: A hospital streamlined patient handoffs during shift changes. Clear communication and standardized procedures led to fewer errors.

- Medication Administration: Nurses collaborated to reduce the steps involved in administering medications, enhancing patient safety.

- Office Environments:

- 5S Methodology: Sort, Set in order, Shine, Standardize, Sustain. Organizing workspaces for efficiency and cleanliness.

- Visual Management: Using visual cues (like Kanban boards) to track tasks and progress.

Related topic category: Continuous Improvement

Remember, Kaizen isn’t about grand gestures—it’s about consistent, purposeful steps toward excellence. As we proceed, we’ll explore more practical examples and insights. In the next section we will discuss Value Stream Mapping.

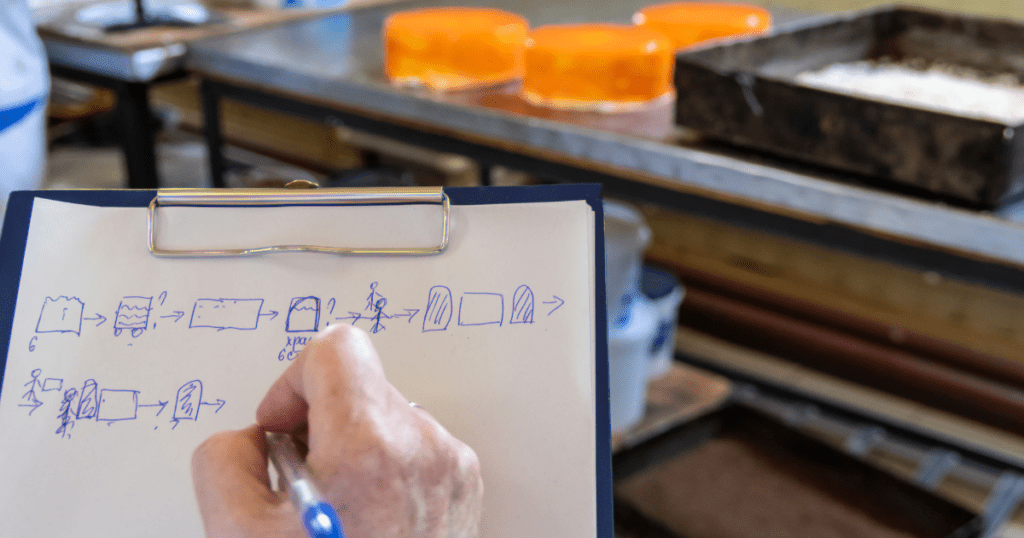

Value Stream Mapping: Unveiling Hidden Opportunities

What is Value Stream Mapping?

Value Stream Mapping is like a GPS for your processes. It provides a visual representation of how work flows from start to finish. Here’s why it matters:

- Visualization: VSM creates a clear picture of the entire process, including material flow, information flow, and decision points.

- Waste Identification: By mapping each step, we spot waste (Muda) and non-value-added activities.

- Bottleneck Detection: VSM reveals choke points where work slows down or piles up.

- Opportunity Exploration: It helps us identify areas ripe for improvement.

Related: Understanding Value-Added and Non-Value-Added Activities: A comprehensive guide

How VSM Works: A Step-by-Step Guide

1. Define the Scope

- Choose a specific process (e.g., order fulfillment, product assembly).

- Determine the boundaries: Where does it start, and where does it end?

2. Create the Current State Map

- Gather a cross-functional team.

- Walk the process, documenting each step.

- Include information on cycle times, inventory levels, and wait times.

- Use symbols (boxes, arrows, and icons) to represent activities, inventory, and information flow.

3. Analyze the Current State

- Look for bottlenecks, delays, and waste.

- Calculate cycle time, lead time, and process efficiency.

- Identify areas where value isn’t being added.

4. Design the Future State

- Brainstorm improvements with the team.

- Remove non-value-added steps.

- Optimize flow, reduce inventory, and streamline decision-making.

- Create a new map representing the ideal process.

5. Implement and Sustain

- Pilot the changes.

- Monitor progress.

- Standardize the improved process.

- Continuously review and refine.

Process Mapping Toolkit Certification Course

Real-Life Example: Order Processing

Imagine a company processing customer orders. The current state map reveals delays due to manual data entry, excessive handoffs, and overproduction of paperwork. The future state map streamlines the process: automated data capture, reduced handoffs, and digital workflows. Result? Faster order fulfilment and happier customers.

Remember, Value Stream Mapping isn’t just about drawing pretty diagrams—it’s about driving meaningful change. Next, we’ll tackle waste reduction strategies.

Waste Reduction and Process Optimization

Identifying the Eight Types of Waste (Muda)

- Overproduction:

- The Culprit: Producing more than what’s needed, leading to excess inventory and wasted resources.

- Strategies:

- Just-in-Time (JIT): Produce only when demand signals pull for it.

- Kanban Systems: Implement visual cues to regulate production flow.

- Batch Size Reduction: Smaller batches minimize overproduction risks.

- Waiting:

- The Culprit: Idle time—whether it’s machines waiting for materials or employees waiting for approvals.

- Strategies:

- Streamline Processes: Identify bottlenecks and reduce wait times.

- Parallel Processing: When possible, allow tasks to happen simultaneously.

- Cross-Training: Ensure employees can perform multiple tasks to avoid waiting.

- Transportation:

- The Culprit: Excessive movement of materials or information.

- Strategies:

- Layout Optimization: Arrange workstations for minimal movement.

- Centralized Storage: Keep frequently used items close to the point of use.

- Digital Communication: Reduce physical document transportation.

- Overprocessing:

- The Culprit: Doing more than necessary—adding features or steps that don’t enhance value.

- Strategies:

- Value-Added Analysis: Identify non-value-added steps and eliminate them.

- Standard Work: Define optimal processes and stick to them.

- Simplify Workflows: Remove unnecessary complexity.

- Inventory:

- The Culprit: Excess stock ties up capital, occupies space, and risks obsolescence.

- Strategies:

- Pull Systems: Produce only when there’s demand.

- ABC Analysis: Rank or prioritize inventory items by Value and Usage.

- Cycle Counting: Regularly audit inventory to prevent overstocking.

- Motion:

- The Culprit: Unnecessary movement by employees or equipment.

- Strategies:

- Ergonomic Design: Optimize workstations for efficiency.

- Visual Management: Clearly mark tools and supplies to minimize search time.

- 5S Methodology: Sort, Set in order, Shine, Standardize, Sustain.

- Defects:

- The Culprit: Errors, rework, and defects that waste time and resources.

- Strategies:

- Poka-Yoke (Error-Proofing): Design processes to prevent mistakes.

- Root Cause Analysis: Investigate defects and address underlying issues.

- Quality Circles: Involve employees in problem-solving.

- Underutilized Talent:

- The Culprit: Not tapping into employees’ full potential.

- Strategies:

- Empowerment: Encourage employees to contribute ideas and improvements.

- Training and Skill Development: Invest in continuous learning.

- Cross-Functional Teams: Leverage diverse skills for problem-solving.

The 8 Wastes of Lean Certification Course

Remember, waste reduction isn’t a one-time event—it’s a mindset. As we optimize processes, we pave the way for excellence. Next, let’s explore employee involvement and engagement.

Also Read: The 8 Wastes of Lean: A Comprehensive Guide

Employee Involvement and Engagement: The Heartbeat of Lean Thinking and Continuous Improvement

Why Involve Employees?

In the Lean journey, employees aren’t mere cogs in the machine—they’re the architects of improvement. Here’s why their involvement matters:

- Fresh Perspectives: Employees working on the frontlines see processes up close. Their insights are invaluable for identifying waste, bottlenecks, and improvement opportunities.

- Ownership and Accountability: When employees actively participate, they take ownership of outcomes. They’re not just following orders; they’re invested in success.

- Problem-Solving Power: Engaged employees become problem solvers. They tackle issues head-on, propose solutions, and drive change.

Engaged Employees: Catalysts for Excellence

- Better Problem-Solving:

- Engaged employees:

- Spot inefficiencies.

- Collaborate to find root causes.

- Implement practical solutions.

- Example: A manufacturing team noticed excessive setup time. They redesigned the process, reducing changeover time by 50%.

- Engaged employees:

- Innovation and Creativity:

- Engaged minds spark innovation:

- They suggest process improvements.

- They experiment with new ideas.

- They adapt Lean principles to unique contexts.

- Example: A healthcare team reimagined patient handoffs, using digital tools to enhance communication and reduce errors.

- Engaged minds spark innovation:

- Sustained Improvement:

- Engaged employees don’t settle:

- They monitor progress.

- They adjust as needed.

- They prevent backsliding.

- Example: An IT department embraced Lean practices. Regular retrospectives ensured continuous learning and adaptation.

- Engaged employees don’t settle:

Related: Develop a Lean Culture Through Employee Involvement Teamworking

Organizations Leading the Way

- Toyota:

- The pioneer of Lean Thinking.

- Employees actively participate in Kaizen events.

- Result: Consistent process improvements and a culture of excellence.

- Zappos:

- The online shoe retailer fosters employee creativity.

- “Zapponians” have the autonomy to innovate.

- Result: A vibrant workplace and exceptional customer service.

- Southwest Airlines:

- Employees are empowered to solve customer issues.

- “LUV” (Southwest’s stock symbol) extends to employees too.

- Result: High employee satisfaction and operational efficiency.

Remember, engaged employees aren’t just assets—they’re the heartbeat of Lean. As we continue, let’s explore Lean culture and leadership.

Lean Culture and Leadership: Beyond Tools, Into Transformation

Cultural Metamorphosis

Lean Thinking isn’t a mere toolbox—it’s a metamorphosis. Here’s why:

- Shared Beliefs and Behaviors:

- Lean transcends processes; it seeps into the DNA of an organization.

- It’s about fostering a mindset of continuous improvement, waste reduction, and respect for people.

- When everyone—from the CEO to the frontline worker—embraces these beliefs, Lean becomes cultural.

- Adaptability and Agility:

- Lean culture thrives on adaptability.

- Teams learn, iterate, and evolve.

- It’s not about rigid adherence to a fixed set of rules; it’s about agility in the face of change.

Leadership’s Crucial Role

- Visionary Leadership:

- Leaders set the tone.

- They articulate the vision of Lean transformation.

- Example: A CEO champions Lean principles, emphasizing their impact on customer satisfaction and long-term success.

- Creating Psychological Safety:

- Leaders encourage experimentation.

- They create an environment where failure isn’t punished but seen as a learning opportunity.

- Example: A manager praises a team for trying a new process—even if it doesn’t yield immediate results.

- Continuous Learning and Adaptation:

- Leaders model curiosity and learning.

- They seek feedback, analyze data, and adjust strategies.

- Example: A director attends Lean workshops, applies new insights, and shares learnings with the team.

The Unwavering Commitment

- Leadership Support:

- Lean isn’t a side project; it’s a strategic imperative.

- Leaders allocate resources, time, and attention.

- Example: A board of directors approves funding for Lean initiatives.

- Persistence and Consistency:

- Lean isn’t a one-time workshop; it’s a lifelong journey.

- Leaders stay committed even when challenges arise.

- Example: A department head ensures regular Gemba walks and Gemba boards become part of the team’s routine.

Lean culture isn’t built overnight—it’s a collective effort, fueled by leadership commitment. As we wrap up, let’s explore real-world case studies and the challenges organizations face on this transformative path.

Case Studies: Lean Thinking and Continuous Improvement Success Stories

1. Toyota (Manufacturing)

Background:

- Industry: Automotive manufacturing.

- Challenge: Toyota faced production inefficiencies, high costs, and quality issues.

Lean Implementation:

- Toyota embraced Lean principles, including JIT production, Kanban, and continuous improvement (Kaizen).

- They empowered employees to identify waste and contribute to process enhancements.

Results:

- Remarkable Efficiency: Reduced production lead times, minimized inventory, and improved quality.

- Cost Savings: Significant cost reductions due to waste elimination.

- Global Influence: Toyota’s success with Lean Thinking influenced the entire automotive industry.

2. Virginia Mason Medical Center (Healthcare)

Background:

- Industry: Healthcare.

- Challenge: Long patient wait times, inefficient processes, and inconsistent quality.

Lean Implementation:

- Virginia Mason adopted Lean principles to streamline patient flow, reduce errors, and enhance care delivery.

- They engaged frontline staff in process improvement initiatives.

Results:

- Reduced Wait Times: Patients experienced shorter wait times for appointments and procedures.

- Improved Safety: Fewer medical errors due to standardized processes.

- Cost Savings: Lower operational costs and better resource utilization.

3. Starbucks (Service)

Background:

- Industry: Retail and service (coffee shops).

- Challenge: Inconsistent customer experiences, slow service, and waste.

Lean Implementation:

- Starbucks applied Lean concepts to their coffee-making process.

- They trained baristas in efficient workflows and waste reduction.

Results:

- Consistent Quality: Uniform coffee quality across all stores.

- Faster Service: Reduced wait times during peak hours.

- Sustainability: Embraced eco-friendly practices, aligning with Lean principles.

4. Amazon (E-Commerce and Logistics)

Background:

- Industry: E-commerce, logistics, and supply chain.

- Challenge: Fulfilling customer orders quickly and accurately.

Lean Implementation:

- Amazon optimized its fulfillment centers using Lean principles.

- They focused on minimizing waste, improving inventory management, and enhancing order processing.

Results:

- Efficient Warehousing: Streamlined processes reduced order fulfilment times.

- Precision Inventory: Reduced excess inventory and stockouts.

- Customer Satisfaction: Faster deliveries and accurate order processing.

These case studies demonstrate that Lean Thinking isn’t just a theory—it’s a powerful approach that drives tangible results. Organizations that embrace Lean principles create a culture of excellence and continuous improvement.

Challenges and Pitfalls in Lean Adoption

- Resistance to Change:

- Challenge: Employees and leadership may resist altering established processes. Change can be uncomfortable, especially if it disrupts familiar routines.

- Mitigation:

- Communication: Transparently communicate the reasons for Lean adoption and the benefits it brings.

- Involvement: Involve employees early on—seek their input and address concerns.

- Education: Provide training on Lean principles and their positive impact.

- Lack of Sustained Commitment:

- Challenge: Lean isn’t a quick fix; it requires ongoing dedication. Organizations often lose momentum after initial improvements.

- Mitigation:

- Leadership Buy-In: Ensure leaders champion Lean as a long-term strategy.

- Measurement and Tracking: Regularly assess progress and celebrate achievements.

- Continuous Learning: Keep the Lean mindset alive through workshops, forums, and knowledge sharing.

- Misapplication of Lean Principles:

- Challenge: Misunderstanding or misusing Lean tools can lead to unintended consequences.

- Mitigation:

- Education: Train employees thoroughly on Lean concepts.

- Contextual Application: Tailor Lean principles to fit the organization’s unique context.

- Avoiding Rigidity: Don’t treat Lean as a rigid set of rules; adapt as needed.

Remember, overcoming these challenges requires persistence, adaptability, and unwavering commitment. Lean isn’t just about tools—it’s about transforming the way we work.

Conclusion: Nurturing Excellence Through Lean Thinking and Continuous Improvement

In our journey through Lean Thinking, we’ve uncovered powerful principles that transcend industries and reshape organizational landscapes. Let’s recap the key takeaways:

- Lean Isn’t Just Tools: It’s a cultural transformation—a way of thinking that permeates every corner of your organization.

- Engage Your People: Employees are your greatest assets. Involve them in problem-solving, innovation, and continuous improvement.

- Leadership Matters: Leaders set the tone. Their commitment, adaptability, and vision drive Lean success.

- Results Speak Louder: Real-world case studies—from Toyota to Starbucks—show that Lean isn’t theoretical; it’s practical and impactful.

Your Next Step

As you close this article, consider how Lean Thinking can revolutionize your work environment. Explore further, experiment boldly, and apply Lean principles with purpose. Remember, excellence isn’t a destination—it’s a journey fueled by continuous improvement.

Thank you for joining us on this Lean voyage.