Table of Contents

I. Introduction

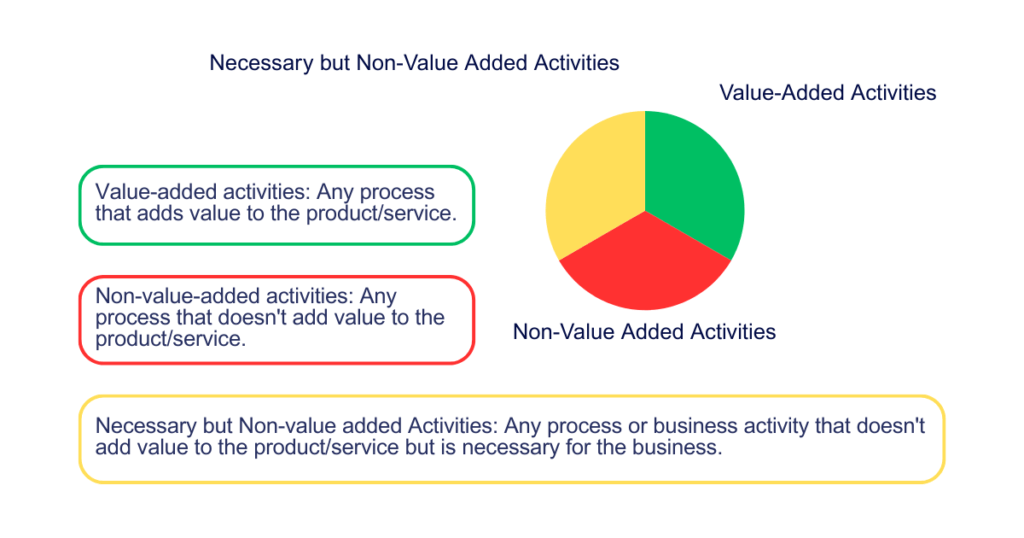

In the world of business and process improvement, two key concepts play a significant role in enhancing efficiency and customer satisfaction: Value-Added and Non-Value-Added Activities. Understanding these concepts is crucial for any organization aiming to streamline its operations, minimize waste, and optimize resources.

Definition of Value-Added and Non-Value-Added Activities

Value-added activities are those that, in the eyes of the customer, enhance the product or service, making it worth more or more desirable. These activities directly contribute to improving the product or service, aligning with customer needs, and enhancing the overall experience. Activities such as assembling products, delivering personalized customer service, providing customized solutions, and enforcing quality control measures serve as examples.

On the other hand, Non-Value-Added Activities are processes or steps that take time, resources, or space but do not increase the product’s value. These activities do not add any value to the end product or service, leading to wasted resources and increased costs.

Importance of Understanding These Concepts

Understanding the difference between Value-Added and Non-Value-Added Activities is essential for businesses aiming to improve their processes and increase efficiency. By identifying and eliminating non-value-added activities, businesses can streamline their processes, reduce waste, and focus their resources on activities that truly add value to their product or service and enhance customer satisfaction.

Origin and History

The concept of value-added activities has its roots in Lean management methodology, which is based on cutting out anything that doesn’t add value. The theoretical starting points for value-added were given by Petty in the seventeenth century, and his work was continued by Adam Smith, David Ricardo, and Karl Marx. The value-added tax (VAT), a related concept, was designed by two people, independently, in the early 20th century. Many European countries enacted a VAT in the 1960s and 1970s, and other countries followed in the 1980s and thereafter.

In the next sections, we will delve deeper into these concepts, providing examples and discussing their impact on business efficiency.

II. Understanding Value-Added Activities

Explanation of Value-Added Activities

Value-added activities refer to the procedures or stages in the production or service operation that significantly enhance the value of a product or service. In essence, these are the activities that customers find worth paying for as they add tangible or perceived value to the product or service. They directly amplify the product’s or service’s value from the customer’s perspective. By fulfilling customer requirements and addressing their needs, these activities become essential, and customers are willing to pay for them.

Examples of Value-Added Activities in Different Industries

Here are some examples of Value-Added Activities in different industries:

- Manufacturing Industry: Assembling components to create a finished product.

- Service Industry: Providing personalized financial advice to clients based on their specific needs and financial goals.

- Software Development: Developing new features that enhance the usability and functionality of a software application.

Related: What Are Value Added Services? (Plus 10 Helpful Examples)

The Impact of Value-Added Activities on Business Efficiency

Value-added activities play a crucial role in enhancing business efficiency. They streamline operations, minimize waste, and optimize resources, ultimately driving success and customer satisfaction. They ensure that businesses utilize resources effectively, complete tasks efficiently, and that the products or services meet or exceed expectations.

By providing these features, businesses can gain a variety of benefits, including attracting customers, standing out from the competition, and increasing rates of customer loyalty. Value-added activities can help businesses reach their goals by providing features that attract more customers and increase profits for the business. By adding unique features to offerings and customer experience, businesses can stand out from the competition. Providing value consistently can encourage customers to return to a business again and support it over time.

Enrol in the Lean Management Certification Course.

III. Understanding Non-Value-Added Activities

Explanation of Non-Value-Added Activities

Non-value-added activities are those tasks within a process that do not enhance the product or service from the customer’s perspective. These activities consume resources and time without improving the product or service quality or enhancing the customer experience. They usually include unnecessary steps, redundancies, delays, or anything that leads to inefficiency. If an activity does not transform resources, isn’t done right the first time, or isn’t desired by the customer, it is considered non-value-adding.

Examples of Non-Value-Added Activities in Different Industries

Here are some examples of Non-Value-Added Activities in different industries:

- Manufacturing Industry: Unnecessary movement of goods or materials.

- Service Industry: Delays in the workflow.

- Software Development: Overproduction, producing more features than what is demanded by the customer.

Related: What Are Non-Value Added Activities & How to Find Them

The Impact of Non-Value-Added Activities on Business Efficiency

Non-value-added activities can have a significant impact on business efficiency. They tie up precious resources—time, labour, materials—that could otherwise be allocated to revenue-generating endeavours. These activities introduce extra steps, prolonging the process duration and raising the probability of errors, rework, and delays. By systematically spotting and addressing non-value-added activities, companies can optimize their processes, thereby eliminating unnecessary costs and enhancing overall efficiency. This strategy allows businesses to maintain competitive pricing in the market while also preserving their profit margins. However, if not addressed, these activities can reduce strategic, organizational, and individual agility, slow down decision-making, reinforce micro-management, and contribute greatly to employee disengagement.

IV. The Difference Between Value-Added and Non-Value-Added Activities

Key Differences Between the Two

Value-Added and Non-Value-Added Activities, while both integral parts of a process, have distinct differences:

- Transformation: Value-added activities transform the product or service towards its completion, making it more desirable to the customer. Non-value-added activities, on the other hand, do not contribute to this transformation.

- Customer Perception: Customers are willing to pay for Value-Added Activities as they enhance the product or service. Non-value-added activities do not increase the product’s value from the customer’s perspective.

- Efficiency: Value-added activities contribute to business efficiency by improving the product or service and meeting customer needs. Non-value-added activities lead to inefficiencies, as they consume resources without adding value.

How to Identify Whether an Activity is Value-Added or Non-Value-Added

Identifying whether an activity is Value-Added or Non-Value-Added can be done by considering the following criteria:

- Modification/Transformation: Does the activity change the product or service in a way that is desirable to the customer?

- Value for Money: Is the customer willing to pay for the change?

- First Time’s the Charm: Is the activity done right the first time, without the need for rework or correction?

If an activity meets all these conditions, it is Value-Added. If it does not, it is considered Non-Value-Added. It’s important to note that some Non-Value-Added Activities may still be necessary due to current technological or regulatory constraints. These are often referred to as ‘Non-Value-Added but Necessary’ activities.

V. The Role of Value-Added and Non-Value-Added Activities in Process Improvement

How These Concepts Fit into Process Improvement Methodologies Like Lean and Six Sigma

Value-Added and Non-Value-Added Activities are fundamental concepts in process improvement methodologies like Lean and Six Sigma. These methodologies aim to enhance efficiency and quality by eliminating waste, which is essentially the non-value-added activities, and optimizing value-added activities.

In Lean, the focus is on cutting waste or non-value-adding operations and actions within a process. Lean provides ways to identify areas of non-value-added and value-added actions. Each step in a process is assessed based on whether it results in enhanced value for the customer. If not, then it needs to go.

Related: VA vs. NVA in Lean Management

In Six Sigma, the goal is to reduce process variation and improve process control, which often involves eliminating non-value-added activities and increasing the efficiency of value-added activities. Six Sigma uses a data-driven approach to identify non-value-added activities and implement improvements.

Related: VA vs NVA In Six Sigma

Case Studies Showing the Application of These Concepts in Process Improvement

- Case Study in India: A small- and medium-scale enterprise in India implemented the Lean-Kaizen concept, which involves the continuous elimination of waste through small improvements. They used non-value-added analysis to review each activity within a business process to ascertain its value contribution. After implementing Kaizen events, they achieved reduced inventory level, reduced lead time, reduced cycle time, rework elimination, improved productivity, and improved product quality.

- Case Study in Inspection Process: A case study was conducted on an inspection process where value-added and non-value-added activities were analyzed. The study found that by focusing on enhancing value-added processes and reducing non-value-added activities, efficiency and productivity were improved.

These case studies demonstrate the practical application of value-added and non-value-added concepts in process improvement and their impact on enhancing business efficiency.

Related: Value And Non- Value Added (VA / NVA) Activities Analysis Of A Inspection Process – A Case Study

Enrol in the Lean Six Sigma Toolkit Certification Course.

VI. Strategies for Increasing Value-Added Activities and Reducing Non-Value-Added Activities

Tips and Strategies for Businesses

- Identify and Understand Your Processes: Map out your business processes and analyze each activity within these processes. This will help you understand which activities are adding value and which ones are not.

- Eliminate or Reduce Non-Value-Added Activities: Once you’ve identified the non-value-added activities, find ways to eliminate or reduce them. This could involve streamlining processes, optimizing resource allocation, and prioritizing tasks that directly contribute to meeting customer needs.

- Focus on Customer Value: Always keep the customer’s perspective in mind. Ensure that your activities are transforming resources, being done right the first time, and are desired by the customer.

- Continuous Improvement: Implement a culture of continuous improvement. Encourage employees to identify and eliminate waste in their own work processes.

- Training and Education: Train your employees on the concepts of value-added and non-value-added activities. This will equip them with the knowledge and skills to identify and eliminate waste in their own work processes.

Potential Challenges and How to Overcome Them

- Resistance to Change: Employees may resist changes to their work processes. Overcome this by communicating the benefits of eliminating non-value-added activities, providing training, and involving employees in process improvement efforts.

- Lack of Understanding: Employees may not understand the concepts of value-added and non-value-added activities. Address this by providing training and education.

- Difficulty in Identifying Non-Value-Added Activities: It can be challenging to identify non-value-added activities. Overcome this by using tools like process mapping and value stream mapping.

Remember, the goal is to maximize the value you provide to your customers while minimizing waste. By focusing on value-added activities and reducing non-value-added activities, you can improve efficiency, reduce costs, and enhance customer satisfaction.

VII. Conclusion

In conclusion, understanding the concepts of Value-Added and Non-Value-Added Activities is crucial in the realm of business improvement and process optimization. These concepts play a significant role in enhancing efficiency, minimizing waste, and optimizing resources.

Value-Added Activities are those that customers are willing to pay for as they enhance the product or service, while Non-Value-Added Activities consume resources without adding value from the customer’s perspective. Identifying and understanding these activities can help businesses streamline their processes, reduce waste, and focus their resources on activities that genuinely add value to their product or service and enhance customer satisfaction.

As we move forward in an increasingly competitive business environment, it is more important than ever for businesses to analyze their processes with these concepts in mind. By doing so, they can ensure that they are providing the maximum value to their customers while minimizing waste and inefficiency.

Remember, the goal is not just to do things right, but to do the right things. So, let’s start identifying what adds value and what doesn’t in our processes, and strive for continuous improvement. Happy analyzing!

Also read: 10 Six Sigma Tools: A comprehensive overview of their application in Root Cause Analysis