Table of Contents

Introduction

In today’s competitive business environment, process improvement is not just a luxury, but a necessity. It plays a pivotal role in enhancing the efficiency and effectiveness of business operations. By identifying, analyzing, and improving existing business processes, companies can reduce waste, increase profits, and foster a culture of continuous improvement.

Process improvement methodologies are systematic approaches that guide businesses in refining their processes. These methodologies provide a structured framework for identifying inefficiencies, implementing improvements, and monitoring the results. They range from Lean and Six Sigma to Agile and Design Thinking, each with its unique focus and approach.

Choosing the right methodology is crucial as it should align with the company’s specific needs, goals, and culture. The right methodology can streamline operations, improve customer satisfaction, and give a business a competitive edge. However, the wrong methodology can lead to wasted resources, employee resistance, and minimal improvements. Therefore, understanding the strengths and applicability of each methodology is essential for successful process improvement initiatives.

Understanding Process Improvement

Business Process Improvement (BPI) is a strategic planning approach designed to pinpoint the operations or employee competencies that could be enhanced to foster more streamlined processes, increased workflow efficiency, and overall business expansion. This systematic approach encourages organizations to maintain efficiency and effectiveness by continuously improving their processes.

The primary goals of process improvement include increased efficiency, reduced costs, improved quality, and enhanced customer satisfaction. By streamlining processes and eliminating unnecessary steps, businesses can achieve greater efficiency and reduce costs. Improving the quality of products or services leads to higher customer satisfaction, which in turn can lead to increased customer loyalty and business growth.

Implementing process improvement methodologies can bring numerous benefits. It can lead to significant cost savings by reducing waste and increasing productivity. It can improve customer service by reducing errors and enhancing the quality of products or services. It can also boost employee morale by creating a more organized and less stressful work environment. Moreover, it fosters a culture of continuous improvement where everyone is always looking for ways to do their work better.

Overview of Process Improvement Methodologies

In the realm of business improvement, there are numerous process improvement methodologies that have been developed and refined over the years. These methodologies, each with its unique focus and approach, provide structured frameworks for businesses to enhance their operations.

In this article, we will delve into various process improvement methodologies such as Lean, Kaizen, PDCA, 5 Whys Analysis, Total Quality Management (TQM), Six Sigma, Theory of Constraints (TOC), Agile, Business Process Reengineering (BPR), Design Thinking, Business Process Management (BPM), Agile Manufacturing, and Business Process Automation (BPA). Each of these methodologies offers unique perspectives and tools for improving business processes.

Despite their differences, all these methodologies share a common goal: to streamline operations and optimize performance. They aim to eliminate waste, reduce variability, improve efficiency, and increase customer satisfaction. By understanding and implementing these methodologies, businesses can achieve significant improvements in their operations and outcomes.

I. Lean Methodology

The Lean methodology originated in the Japanese manufacturing industry, specifically within the Toyota Production System. This is a structured approach to reducing waste in a manufacturing system, without compromising on productivity.

Lean principles focus on examining the flow of materials and information logically as they add value to the product. The five fundamental principles of Lean are:

- Identifying Value: This involves understanding what the customer values in the product or service. It sets the direction for the Lean journey.

- Value Stream Mapping: This is the process of mapping out all steps, both value-adding and non-value-adding, involved in delivering the product or service. It helps to visualize waste and sources of waste.

- Creating Flow: Once the value and the value stream have been identified, the next step is to create a flow by eliminating waste. This means the product should move smoothly towards the customer without any interruptions, detours or waiting.

- Establishing Pull: This principle means that nothing is produced by the upstream process until the downstream process signals a need for it. This strategy helps to prevent overproduction.

- Pursuing Perfection: This is the process of continuous improvement. Once the value has been specified, value streams have been identified and flow and pull have been introduced, you start again and continue until a state of perfection is reached where perfect value is created with no waste.

To illustrate how Lean principles can be applied in different business scenarios, let’s consider a software development company. Identifying value could mean understanding what features the end-users value in the software. Value stream mapping could involve mapping out all the steps in the software development process, from requirement gathering to software maintenance. Creating flow could mean ensuring that coding, testing, and deployment are carried out smoothly without delays. Establishing pull could mean that new features are not developed until there’s a demand for them from the end-users. Pursuing perfection would involve continuously improving the software development process to deliver high-quality software in the most efficient manner.

Enrol in the Lean Management Certification Course.

II. Kaizen (Continuous Improvement)

Kaizen is a Japanese term that translates to “change for the better” or “continuous improvement.” It is a philosophy that focuses on continuous improvement in all aspects of life, from personal life to professional work and social activities. In the business context, Kaizen involves all employees – from the CEO to the assembly line workers – working together proactively to achieve regular, incremental improvements in the process.

A key concept in Kaizen is the Toyota 3M model, which identifies three types of waste (Muda, Mura, Muri):

- Muda: This refers to seven kinds of waste: overproduction, waiting, transportation, overprocessing, inventory, motion, and defects.

- Mura: This refers to unevenness in operations, which can cause overburden and stress in the workforce and processes.

- Muri: This refers to overburden when a machine or person is pushed beyond their natural limits.

To illustrate the successful implementation of Kaizen, let’s consider the case of Toyota. The company is renowned for its efficient manufacturing system, much of which is due to its implementation of Kaizen. Through continuous improvement efforts, Toyota has managed to reduce waste, improve quality, and increase efficiency in its production processes.

Another example is the Virginia Mason Medical Center in Seattle, which adopted the Kaizen philosophy in 2002. By involving all employees in continuous improvement efforts, the hospital was able to make numerous small changes that led to significant improvements in patient care and operational efficiency.

Enrol in the Continuous Improvement Certification Course.

III. PDCA (Plan-Do-Check-Act) Cycle

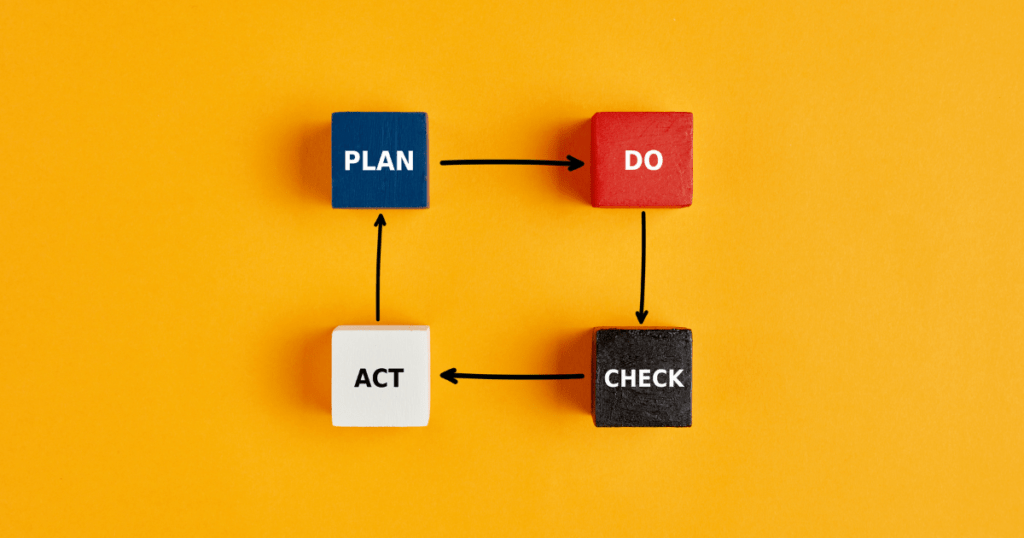

The PDCA cycle, also known as the Deming Cycle, is a problem-solving model used for improving processes and products. It is a continuous loop of planning, doing, checking, and acting that promotes a culture of continuous improvement.

Here’s a detailed explanation of the four steps:

- Plan: Identify a problem or opportunity for improvement. Establish the goals and processes required to achieve the expected results.

- Do: Implement the plan and carry out the process. Gather data for analysis and comparison in the subsequent ‘CHECK’ and ‘ACT’ stages.

- Check: Review the actual outcomes and compare them to the expected outcomes to identify any variances. Look for any deviations from the plan during implementation and also assess the plan’s adequacy and completeness to facilitate execution.

- Act: Call for corrective actions on significant differences between actual and planned results. Analyze the variances to identify their root causes. Determine where to apply changes that will lead to process or product improvement.

To illustrate the application of the PDCA cycle, let’s consider a manufacturing company that wants to reduce its product defects. In the Plan phase, the company identifies the problem (high defect rate) and establishes a plan to reduce defects. In the Do phase, the company implements the plan, which could involve training workers, updating machinery, or changing suppliers. In the Check phase, the company measures the results and finds that the defect rate has decreased but not as much as expected. In the Act phase, the company investigates why the plan didn’t achieve the expected results and discovers that one of the machines still needs updating. The company then cycles back to the Plan phase to update the machine and further reduce defects.

Enrol in the PDCA (Plan-Do-Check-Act) Certification Course.

IV. 5 Whys Analysis

The 5 Whys Analysis is a simple yet powerful tool for root cause analysis. Originally developed by Toyota, it’s used in problem-solving, quality improvement and defect prevention efforts. The premise of this technique is that asking “why” five times from the effect to the cause can lead to the root of the problem.

The process involves starting with the final problem and asking “why” it happened. Each response sets the stage for the next question. The number five is a guideline suggesting that usually by the time you’ve asked “why” five times, you’ve uncovered the root cause of the problem.

Let’s consider a case study to illustrate the effectiveness of the 5 Whys Analysis. Suppose a software company is facing a problem where their software application is running slow. Here’s how they might apply the 5 Whys Analysis:

- Why is the application running slow? The server CPU usage is at 100%.

- Why is the server CPU usage at 100%? There’s a memory leak in the application.

- Why is there a memory leak in the application? A piece of code doesn’t free up memory after it’s done.

- Why doesn’t the code free up memory? The developer who wrote it didn’t know about the memory management requirement.

- Why didn’t the developer know about the memory management requirement? There’s no documentation or training for developers on memory management.

The root cause of the problem is the lack of documentation or training for developers on memory management. By addressing this root cause, the software company can prevent this problem from happening again in the future.

Enrol in the 5 Whys Diagram Certification Course.

V. Total Quality Management (TQM)

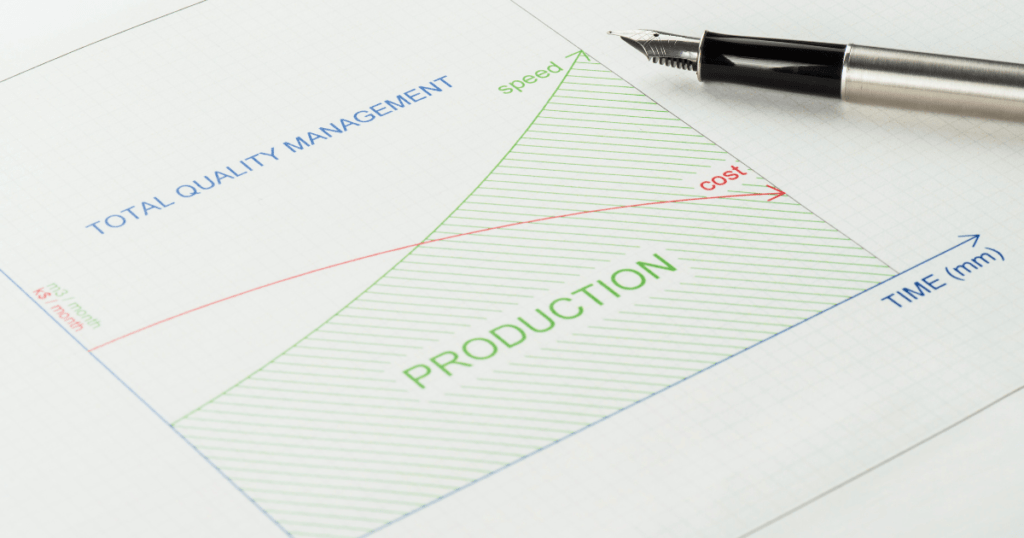

Total Quality Management (TQM) is a managerial strategy that was first introduced in the 1950s and has progressively gained popularity since the early 1980s. TQM means that the organization’s culture is defined by and supports the constant attainment of customer satisfaction through an integrated system of tools, techniques, and training. Continuous Improvement of organizational procedures is involved, leading to top-notch products and services.

TQM is founded on the concept that everyone participating in the production or consumption of the organization’s offerings shares the responsibility for the quality of products and processes. This calls for the collaboration of management, staff, suppliers, and customers to meet or even exceed customer expectations.

The eight key principles of TQM are:

- Customer-focused: The customer ultimately determines the level of quality. Regardless of the measures an organization takes to promote quality enhancement—be it training staff, incorporating quality into the design procedure, or updating computers or software—it’s the customer who decides the value of these efforts.

- Total employee involvement: All staff members contribute to achieving shared objectives. Full employee dedication can only be achieved once fear has been eliminated from the workplace.

- Process-centered: A crucial aspect of TQM is an emphasis on process-oriented thinking. A process is a sequence of actions that take inputs from suppliers (either internal or external) and convert them into outputs that are delivered to customers (either internal or external).

- Integrated system: All elements (departments) of an organization need to function harmoniously for maximum efficiency and effectiveness.

- Strategic and systematic approach: The strategic plan must integrate quality as a core component.

- Continual improvement: Using analytical, quality-driven tools and methodologies for business improvements.

- Fact-based decision-making: Decision-making must be driven by data, not hunches or guesses.

- Communications: Communication strategy, method and timeliness must be defined in a project.

To illustrate the application of TQM, let’s consider the case of Motorola, a company that implemented TQM and won the Malcolm Baldrige National Quality Award in 1988. Motorola used TQM to bring about significant improvements in its product quality and reliability, reducing its manufacturing costs and waste. This led to increased customer satisfaction and allowed Motorola to gain a competitive edge in the market.

Enrol in the Total Quality Management (TQM) Certification Course.

VI. Six Sigma Methodology

Six Sigma is a quality management approach that Motorola introduced in 1986. It employs statistical techniques to enhance quality by reducing variability in business operations, ranging from manufacturing to engineering and procurement. The core principle of Six Sigma is that by quantifying the number of defects in a process, you can methodically determine how to eradicate them and strive to achieve near-zero defects.

A key aspect of Six Sigma is the DMAIC process, an acronym for Define, Measure, Analyze, Improve, and Control:

- Define: Identify the problem or the process improvement opportunity.

- Measure: Quantify the problem and gather data.

- Analyze: Use data to analyze the problem or process to identify root causes.

- Improve: Develop, test, and implement a solution to the problem; seek to improve the process.

- Control: Keep track of the improvements to guarantee ongoing and lasting success.

To illustrate the successful application of Six Sigma, let’s consider the case of General Electric (GE). In the late 1990s, GE’s CEO Jack Welch adopted Six Sigma and made it a part of the company’s culture. By applying Six Sigma principles, GE saved an estimated $12 billion over five years, reduced defects, improved customer satisfaction, and increased profits.

Another example is Ford Motor Company, which implemented Six Sigma in the early 2000s. Through Six Sigma, Ford was able to reduce the number of vehicle recalls, improve the design of their vehicles, and save an estimated $300 million during the first two years of implementation.

Enrol in the Lean Six Sigma White Belt Certification Course.

VII. Theory of Constraints (TOC)

The Theory of Constraints (TOC) is a management paradigm introduced by Dr. Eliyahu M. Goldratt in his 1984 book titled “The Goal”. It asserts that any manageable system is limited in achieving more of its goals by a very small number of constraints and that there is always at least one constraint. The TOC approach aims to pinpoint the limitation and reorganize the entire organization around it, utilizing five key steps for focus.

The five-step process for applying TOC is known as Identify, Exploit, Subordinate, Elevate, Repeat (IESER):

- Identify: Determine what the limiting factor(s) or bottleneck(s) are in the process that is preventing the system from achieving more of its goal.

- Exploit: Make quick improvements to the throughput of the bottleneck(s) using existing resources.

- Subordinate: Review all other activities in the process to ensure that they are aligned with and truly support the needs of the bottleneck(s).

- Elevate: If the bottleneck(s) still exists, consider major actions to eliminate the constraint or turn it into a non-constraint.

- Repeat: After breaking a constraint, go back to step 1 and find the new constraint.

To illustrate how TOC can be used to optimize processes, let’s consider a manufacturing company that has identified a particular machine as a bottleneck in its production process. By applying the TOC, the company can focus on improving the efficiency of this machine (Exploit), adjusting the workflow to ensure that this machine is always working at maximum capacity (Subordinate), and considering investment in additional machines if the bottleneck persists (Elevate). This process is then repeated to continually improve the production process.

Enrol in the Theory of Constraints Certification Course.

VIII. Agile Methodology

Agile methodology is an approach to project management, typically used in software development. It refers to a set of principles for software development under which requirements and solutions evolve through the collaborative effort of self-organizing cross-functional teams. It advocates adaptive planning, evolutionary development, early delivery, and continuous improvement, and it encourages flexible responses to change.

There are several frameworks that implement the Agile methodology, including Scrum, Kanban, and Lean-Agile:

- Scrum: This framework divides the project into small work units known as sprints, which usually last one to four weeks. The team meets daily to discuss progress and roadblocks in daily stand-up meetings.

- Kanban: This method visualizes the workflow of a project. Work items are represented visually on a board, allowing team members to see the state of every piece of work at any time.

- Lean Agile: This is a combination of Lean and Agile principles and practices. It focuses on delivering value to the customer by achieving efficiency through continuously improving the workflow.

To illustrate the use of Agile methodologies, let’s consider a software development company that has adopted Agile. By using Scrum, the company can break down its software development process into sprints, allowing it to quickly adapt to changes and deliver functional software faster. With Kanban, the company can visualize its workflow and identify bottlenecks in the process. By applying Lean Agile principles, the company can continuously improve its processes, reduce waste, and deliver more value to its customers.

Another example is the British Broadcasting Corporation (BBC), which used Agile methodologies to deliver the largest content management system in the world, used by thousands of journalists globally. The Agile approach allowed the BBC to deliver a project of this scale successfully, with regular releases and feedback loops ensuring that the system met the needs of its users.

IX. Business Process Reengineering (BPR)

Business Process Reengineering (BPR) is a strategic approach that focuses on the analysis and design of workflows and processes within an organization. BPR strives to assist organizations in radically reevaluating their work processes with the goal of significantly enhancing customer service, reducing operational expenses, and emerging as top-tier competitors.

The focus of BPR is on radical change, as opposed to incremental change. It involves a complete transformation of business processes, not just minor adjustments or improvements. The objective is to realize substantial enhancements in key performance indicators, such as cost, quality, service, and velocity.

The steps involved in BPR are:

- Identify: Determine the business processes that need to be reengineered. These are typically those that impact the company’s strategic objectives and customer satisfaction the most.

- Analyze: Document and analyze the existing processes to understand the current state, identify problems, and determine areas for improvement.

- Redesign: Develop new process designs to achieve dramatic improvements in performance. This involves “rethinking” existing business processes and often requires innovative thinking.

- Implement: Put the new process designs into practice. This often involves significant changes in how work is performed and may require changes in business structure, policies, procedures, and use of technology.

- Evaluate: Monitor the reengineered processes to ensure they are delivering the expected results, and make adjustments as necessary.

To illustrate the successful implementation of BPR, let’s consider the case of Ford Motor Company. In the early 1990s, Ford implemented a major BPR project to reduce overhead and improve quality, speed, and service. The company reengineered its procurement process, which resulted in a reduction in the number of invoices processed and a significant decrease in administrative costs. This BPR project helped Ford to achieve dramatic improvements in its business operations.

X. Design Thinking

Design Thinking is an innovation strategy centred around the human experience that harmonizes the needs of individuals, the potential of technology, and the prerequisites for business prosperity. It’s a technique employed by designers to tackle intricate challenges and discover appealing solutions for customers. Design Thinking utilizes logic, creativity, intuition, and systematic thinking to investigate what could potentially exist, and to generate preferred results that advantage the ultimate user (the consumer).

Design Thinking involves five stages, though these stages do not have to be followed in any specific order and can often occur in parallel and be repeated iteratively. The five stages are:

- Empathize: Understanding what they really want of those who you are designing for.

- Define: Constructing a point of view that is based on user needs and insights.

- Ideate: Brainstorming and coming up with creative solutions.

- Prototype: Building a representation of one or more of your ideas to show to others.

- Test: Going back to your initial user group and evaluating your concepts for their feedback.

To illustrate how Design Thinking can be applied, let’s consider a tech company that wants to create a new app. In the Empathize stage, the company might conduct interviews and surveys to understand the needs of the users. In the Define stage, they would use this information to define the main problems the app should solve. In the ideation stage, they would brainstorm different ideas for the app. In the Prototype stage, they would create a mock-up or a minimum viable product (MVP) of the app. Finally, in the Test stage, they would test the app with a group of users and collect feedback for further improvements.

XI. Business Process Management (BPM)

Business Process Management (BPM) is a way of using different methods like modelling, automation, carrying out, controlling, measuring, and making better the flow of business activities. It helps to reach the goals of the business. It involves systems, employees, customers, and partners both inside and outside the business.

The focus of BPM is on end-to-end process optimization, aiming to design, model, execute, monitor, and optimize important business processes. The goal is to improve agility and operational performance.

The BPM lifecycle involves five stages:

- Design: Identify existing processes and design “to-be” processes. Areas of improvement are discovered and the future state of the process is modelled.

- Model: Simulate the change to the process. This step is about determining what the new process outcomes will be and how they will perform.

- Execute: Implement (or execute) the new process, either in small steps or on a grand scale. Execution can be manual or automated.

- Monitor: Monitor the processes. This can be done with simple physical observation techniques or more sophisticated software tools.

- Optimize: Identify the bottlenecks and gaps in the new process and optimize for better performance.

To illustrate the use of BPM, let’s consider a healthcare provider aiming to reduce patient wait times. In the Design stage, they map out the current patient journey and identify bottlenecks. In the Model stage, they simulate changes to the process, such as adding more staff during peak times. In the execution stage, they implement these changes. In the Monitor stage, they track patient wait times to ensure the changes are having the desired effect. Finally, in the Optimize stage, they make further adjustments to continue improving patient wait times. Through BPM, the healthcare provider is able to provide a better service to its patients and improve its operational efficiency.

XII. Agile Manufacturing

Agile Manufacturing is a modern approach that focuses on flexibility, responsiveness, and collaboration to meet the ever-changing demands of customers and the market. It’s about being able to adapt quickly and effectively to changes, whether they’re in customer demand, market conditions, or technological advancements.

Agile Manufacturing employs various strategies to achieve its goals. Two such strategies are Quick Response Manufacturing (QRM) and Flexible Manufacturing Systems (FMS).

- Quick Response Manufacturing (QRM) is a strategy that emphasizes reducing lead time across all aspects of an organization. The goal is to respond to customer demands in the shortest possible time, thereby increasing competitiveness and market share.

- On the other hand, Flexible Manufacturing Systems (FMS) are designed to adapt quickly to changes in product type and volume. These systems use high-tech equipment and software to automate and integrate many production processes, allowing for greater flexibility and efficiency.

Let’s look at some examples of how Agile Manufacturing principles can be applied:

- Automotive Industry: An automobile manufacturer could use FMS to switch production between different models based on real-time market demand. This allows them to respond quickly to trends and customer preferences, reducing inventory costs and improving customer satisfaction.

- Electronics Industry: An electronics company could implement QRM to reduce the time from product design to market launch. By streamlining processes and eliminating waste, they can get their products to market faster than competitors, a crucial advantage in a rapidly evolving industry.

- Custom Manufacturing: A custom furniture maker could use Agile Manufacturing principles to offer a wide range of products without a significant increase in production time or cost. By using advanced manufacturing techniques and software, they can quickly switch between different product designs, offering customers a high degree of customization without the long wait times traditionally associated with custom-made products.

In conclusion, Agile Manufacturing is about being adaptable, responsive, and efficient in a dynamic market environment. By implementing strategies like QRM and FMS, businesses can improve their ability to meet changing customer demands, ultimately leading to improved production efficiency and business success.

XIII. Business Process Automation (BPA)

Business Process Automation (BPA) is the use of technology to automate repetitive tasks and streamline workflows within an organization. It’s about making processes more efficient and effective, reducing the chance of errors, and freeing up employees’ time to focus on more strategic tasks.

BPA leverages various tools and platforms to achieve its goals. Two such tools are Robotic Process Automation (RPA) and Workflow Management Systems.

- Robotic Process Automation (RPA) is a type of technology that uses computer programs or ‘bots’ to do regular tasks automatically. These bots can interact with digital systems and software just like a human user would, performing tasks such as data entry, processing transactions, or responding to simple customer service queries.

- Workflow Management Systems, on the other hand, are tools designed to streamline the coordination of tasks between people and systems. They provide a structured interface for organizing and tracking all the tasks involved in a workflow, ensuring that each task is carried out in the most efficient order and that no steps are missed.

Now, let’s look at some case studies that demonstrate the benefits of BPA:

- Banking Industry: A large bank implemented RPA to automate its loan application processing. The bots were able to quickly and accurately gather information from various sources, perform credit checks, and even make preliminary decisions on whether to approve or reject the applications. This reduced the processing time from several days to just a few hours, improved accuracy by eliminating human errors, and allowed bank employees to focus on more complex and personalized customer service tasks.

- Healthcare Industry: A hospital used a workflow management system to streamline its patient admission process. The system coordinated tasks between various departments, ensuring that each step of the admission process was completed in the correct order and in a timely manner. This not only improved the efficiency of the admission process but also enhanced the patient experience by reducing waiting times.

- Retail Industry: An online retailer implemented BPA to automate its order fulfilment process. The system was able to automatically process orders, update inventory, and coordinate with shipping providers to ensure that customers received their purchases as quickly as possible. This not only increased the retailer’s productivity but also improved customer satisfaction by ensuring timely and accurate deliveries.

In conclusion, Business Process Automation is a powerful tool for any organization looking to improve efficiency, reduce errors, and enhance productivity. By choosing the right BPA tools and strategies, businesses can transform their operations and achieve significant improvements in performance and customer satisfaction.

Enrol in the Business Process Automation Certification Course.

Selecting the Right Process Improvement Methodology

Choosing the right process improvement methodology is crucial for the success of any business improvement initiative. It’s not a one-size-fits-all situation, and the most effective approach can vary depending on the specific needs and objectives of your organization.

When selecting a methodology, it’s important to consider additional process improvement methodologies beyond those discussed in this article. There are numerous other methodologies out there, each with its own unique strengths and focus areas. Some may be more suited to large-scale transformations, while others may be ideal for smaller, incremental improvements.

A comparative analysis of the strengths, weaknesses, and applicability of each methodology can be incredibly helpful in making this decision. For instance, Lean is excellent for eliminating waste and improving efficiency, but it may not be the best choice if your primary goal is to improve product quality, in which case Six Sigma might be a better fit. Similarly, Agile Manufacturing is great for businesses needing to adapt quickly to changing market demands, but it might not be as effective for businesses in more stable, predictable industries.

It’s also worth noting that these methodologies are not mutually exclusive. In fact, many businesses find that leveraging a combination of methodologies allows them to better address their unique needs and objectives. For example, a company might use Lean principles to streamline their processes, and then use Six Sigma techniques to reduce defects in the improved process. Alternatively, a company might use Business Process Automation to handle repetitive tasks, freeing up their employees to focus on tasks that require human creativity and problem-solving skills.

In conclusion, selecting the right process improvement methodology is a strategic decision that can significantly impact your business’s efficiency and success. By carefully considering your organization’s specific needs and objectives, and by understanding the strengths and weaknesses of each methodology, you can choose the approach that will bring the most value to your business. Remember, the goal is not to implement a methodology for the sake of it, but to improve your business in a way that aligns with your strategic objectives. So, choose wisely!

Implementing Process Improvement

Implementing process improvement methodologies involves a series of steps that ensure the changes are effective and sustainable. Here are the typical steps involved:

- Assessment: This is the initial stage where you identify the processes that need improvement. It involves understanding the current state of the process, identifying pain points, and defining the problem clearly.

- Planning: In this stage, you design the solution. This involves setting clear goals, developing a detailed plan of action, and deciding on the specific methodology or combination of methodologies to use.

- Execution: This is when we start doing what we planned. The proposed changes are implemented in the process. This could involve changes in the workflow, use of new tools, or even a complete overhaul of the process.

- The proposed changes are implemented in the process. This could involve changes in the workflow, use of new tools, or even a complete overhaul of the process.

- Monitoring: Once the changes are implemented, it’s important to monitor the process closely. This involves collecting data, tracking performance against the set goals, and making sure the changes are having the desired effect.

- Evaluation: The final step is to evaluate the results. This involves analyzing the data collected during the monitoring stage, assessing whether the goals have been met, and determining the overall effectiveness of the process improvement initiative.

Successful implementation of process improvement methodologies requires more than just following these steps. It also involves:

- Employee Involvement: Employees who are involved in the processes being improved should be actively involved in the improvement initiative. Their insights can be invaluable, and their buy-in can greatly increase the chances of success.

- Training: Employees need to be trained in the new processes and methodologies. This ensures that everyone understands the changes and knows how to work within the new system.

- Communication: Clear and regular communication is key throughout the process. Everyone involved should understand the goals of the initiative, the changes being made, and their role in the process.

Implementing process improvement methodologies can be challenging, but these challenges can be overcome with careful planning and execution. Here are some tips:

- Start small: Instead of trying to overhaul an entire process at once, start with a small, manageable part of the process. This allows you to test your approach, learn from the experience, and build momentum for larger changes.

- Involve everyone: Process improvement is a team effort. Make sure everyone involved understands their role and feels a sense of ownership over the process.

- Be patient: Process improvement takes time. Don’t expect immediate results. Instead, focus on making steady progress towards your goals.

In conclusion, implementing process improvement methodologies is a strategic initiative that can significantly enhance your business’s efficiency and effectiveness. By following these steps and tips, you can ensure a successful implementation and reap the benefits of your improvement efforts.

Conclusion

In this comprehensive guide, we’ve explored a wide range of process improvement methodologies, each with its unique strengths and focus areas. From Lean and Six Sigma to Agile Manufacturing and Business Process Automation, these methodologies offer various strategies for enhancing business efficiency.

The key takeaway is the importance of continuous improvement in sustaining business success. In today’s dynamic business environment, standing still is not an option. Businesses must continually strive to improve their processes, reduce waste, increase efficiency, and enhance customer satisfaction to stay competitive.

However, it’s crucial to remember that there’s no one-size-fits-all solution when it comes to process improvement. The most effective approach can vary depending on your specific business needs and objectives. Therefore, it’s essential to understand the strengths and weaknesses of each methodology and choose the one (or a combination) that best aligns with your strategic goals.

In conclusion, I encourage all businesses to explore and adopt process improvement methodologies tailored to their unique requirements. Remember, the goal is not just to implement a methodology for the sake of it, but to drive meaningful and sustainable improvements that align with your business objectives. So, explore, experiment, and embrace the journey of continuous improvement. It’s a journey that leads to not just better processes, but a better business.