Table of Contents

I have written this article to educate you on continuous improvement. The reason for this is that I believe, continuous improvement can often get a bad name. That is because, in many organisations, continuous improvement is deployed badly, incorrectly or by those who don’t truly know how to deploy it or have any shred of passion for it.

Indeed, in the many organisations with which I have worked, I have seen continuous improvement deployed badly or incorrectly time and time again. You have people delivering it that don’t have the right training or qualifications. You have managers that lead on it but don’t really have the passion for it. You have teams who have been sold the vision and purpose of it incorrectly, therefore they don’t know how and when to properly utilise their Continuous Improvement Team.

In this article, I want to run through what continuous improvement is, how it can be deployed, its benefits, indicators and different potential approaches. When deployed correctly, continuous improvement can generate some really fantastic results, repeated time and time again to great effect, setting your organisation up for long-term sustainable success, today.

The fundamentals of continuous improvement

What is continuous improvement?

At a definition level, continuous improvement is the ongoing improvement of products, services and processes through incremental and breakthrough improvements. When it comes to this definition, notice the stress on the word ongoing. Continuous improvement is not a one-off activity, or at least it shouldn’t be. Continuous improvement is an activity that should be occurring yesterday, today and tomorrow. It is something that should be embedded into the culture and the daily activities of the staff, the managers and the leadership.

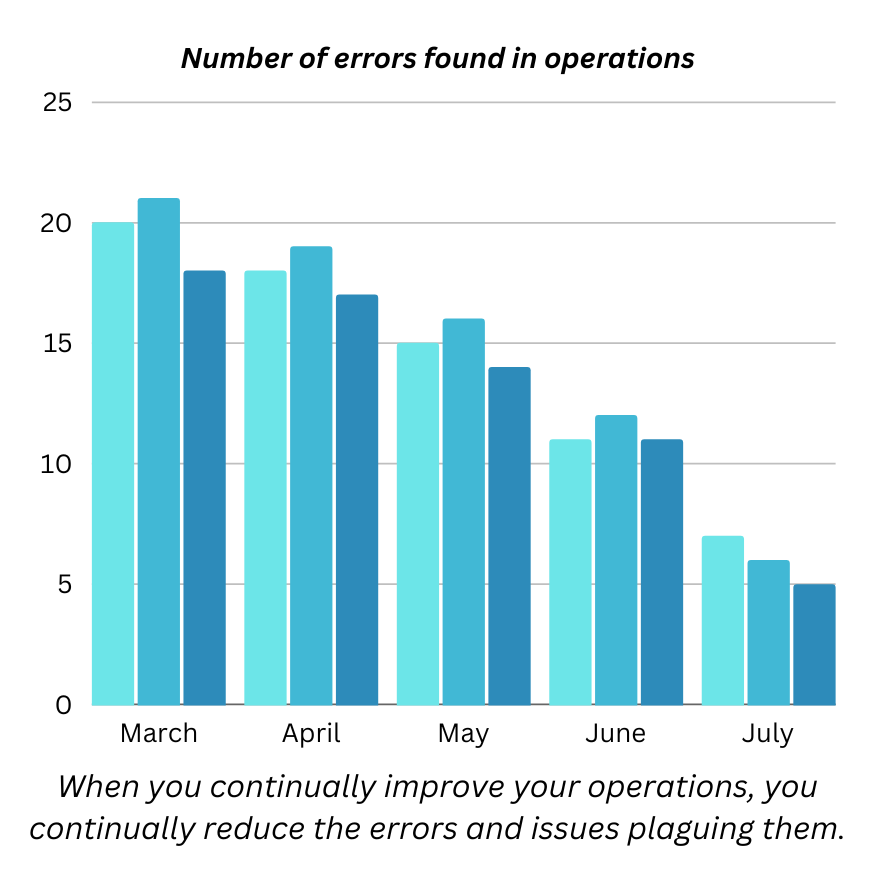

The aim of continuous improvement is to improve the state of something, then improve it again, and again. It is the continual effort to get something to be operating as effectively, efficiently and as productively as possible, removing waste, errors and bottlenecks, whilst increasing value and opportunities. How you achieve these things depends on a raft of criteria, such as your business needs, the resources at its disposal and the level of acceptance of change you have within the culture of your business.

It goes without saying. Those organisations with open, accepting cultures that embrace and celebrate change are the ones who will do significantly better in their continuous improvement journeys.

The purpose of continuous improvement

When it comes to understanding the purpose of continuous improvement, it is important to remember the desired outcome of any work done in this space. Every organisation, team or project will have a different outcome in mind, based on their needs at that time. These needs can evolve, and that is why continuous improvement can be so effective. It is not done just one time and no more – it happens again and again and can evolve with the needs of the organisation.

When seeking to embark on a continuous improvement initiative, it is really important you are clear from day 1 exactly what you want to outcome of your work to be – what is the purpose? There can be many purposes of continuous improvement, and they can cover the following:

- Reduction of waste

- Improvement of quality

- Ensuring the achievement of SLAs and KPIs

- Reducing the cost of doing business

- Increasing time savings for future investment

- Improving processes and delivering operational excellence throughout

- Improving team mindset and the culture of the team

- Proactively and reactively reducing issues and errors

- Embedding innovation and competitiveness into the organisation

As you can see, the purpose, the reason and the motivating factor behind why you may want to deliver continuous improvement can vary greatly, and each project, process and approach can have different purposes. What matters here is – what suits the needs of the business, today.

Here’s a scenario

The situation

The procurement department has, recently, been procuring services from unsuitable potential providers. They have been scheduling meetings, and demonstrations and discussing commercials way ahead of time.

The problem

This is leading to a big waste of time for the procurement department itself, as well as others within the business who are being called upon from an SME perspective to support in those meetings.

We are also seeing a delay in the procurement of new services and concerns raised across the business.

The effect

Increase in complaints from internal stakeholders, several hours a week now wasted for the procurement and related teams, and disaffected potential future suppliers (complaints about your organisation wasting their time).

The investigation

Upon investigating why this was happening, it became apparent there was no effective RFI process in place, there were no checks and balances in the procurement team (and often in the 3rd party) and a lack of knowledge of what’s needed.

The solution

A continuous improvement initiative was launched. This saw the building of a new RFI process, upskilling the team and changing their SOPs. CI was also embedded by continually reviewing the approach and building in robust control measures.

The purpose here was to use CI to build a new, more effective approach to procurement to proactively reduce issues.

The benefits of continuous improvement

Tied very much with the purpose of continuous improvement, it is also worth thinking about the benefits. When you are looking to pitch or sell your vision for continuous improvement to leaders and those who will have to give it sign-off, they will be looking for the benefits. What is the return on investment of any time spent doing this work or money spent delivering the solutions that come from this work? With that in mind, it is really important you get clear on the benefits of what you are doing early on, just as you need to do with the purpose. By doing so, you are far more likely to get buy-in and support from wider stakeholders.

When it comes to the benefits, this will largely depend on what it is you are trying to achieve, why and how. With that said, there are a range of benefits that can come from continuous improvement that can often be applied across a range of initiatives. The kinds of benefits can include the following:

- Delivering a new culture, one that is stronger, more open

- Transparent and collaborative

- Reducing the waste within your processes and operations

- Guaranteeing better quality of products and service year-on-year

- Shifting the work done to more value-adding in nature

- Ensuring the faster delivery of products and services to market,

- Putting innovation at the heart of the organisation’s strategy

- Reducing errors and defects

- Making the organisation more streamlined

- Improving customer satisfaction and employee engagement

As you can see, the benefits of successfully delivering continuous improvement are vast and are many. That is why, throughout this article, I will stress the importance of not just delivering continuous improvement, but delivering it correctly. Only then can such benefits be truly realised.

Also read: Why you must continually evaluate and improve business processes.

How NOT to deploy continuous improvement

Just as with delivering continuous improvement for positive benefits, and potentially experiencing that positive ripple effect across the organisation, continuous improvement can be deployed incorrectly. Indeed, the continuous improvement being deployed incorrectly has become commonplace in a lot of organisations that don’t truly understand it, don’t have the right level of training amongst their team or have not set the right goals, challenges and metrics against continuous improvement team performance.

With that said, there are a number of key things you SHOULD NOT do when it comes to delivering continuous improvement. Here are 6 of them:

- Delivering projects with no control measures. Delivering new processes, changes, reforms, improvements or entire projects and not ending this work with a control phase can be fatal. Many individuals and organizations don’t fully grasp the importance of putting strong control measures in at the end of such work, to ensure the changes last the test of time. What often happens when such measures are not put in place, is all of that hard work unravels and creates more issues than were there to begin with.

- No methodology. If the managers in the continuous improvement team or the team members themselves are not fully skilled in this art, many will not know about the great array of methodologies out there, designed to help with the delivery of continuous improvement. I remember one time working with a team and I mentioned that they should probably take a Plan Do Check Act approach for their small project, and they had no clue what I was talking about. There were no qualified Lean Six Sigma belts present – nothing. Safe to say, this team was not producing the high-quality positive outputs they should have been.

- No goals or targets. Many organizations who don’t truly understand continuous improvement, often do not know how to set goals and targets for its successful completion. If you do not truly know the impact it can have, how it should be delivered and its potential, how can you adequately plan the outcomes of the work? With this, many leaders do not sign off on the implementation of continuous improvement in their companies because they simply do not understand (often because of the one pitching the work) the return on investment of this endeavour.

- Rewriting the rules. There are tried and tested methods and approaches in place that have worked for organizations of all sizes, types and in all industries – do not try and rewrite these. These methods can be tailored, they are flexible, and they can be combined with others depending on needs and expectations, but trying to rewrite the rules of this game simply will not work. Seeing first-hand individuals with no real knowledge of continuous improvement methodologies try to rewrite them, in their own image, was truly eye-opening. The impact of what was delivered was extremely negative, time consuming and no good came from this.

- Being too top-down. You need to ensure you get buy-in for the approach across the board, not just at the leadership level. In my experience, those organizations that deliver top-down approaches to continuous improvement rarely succeed. This is because they don’t garner the support of those at the coalface of the work, they don’t truly understand the issues plaguing processes and they often don’t understand the impact the work they are imposing on others will have. This can lead to complaints about lack of transparency, lack of interest in resourcing issues and lack of engagement and involvement across the board.

- Not anticipating the knock-on. A big problem faced when people don’t deploy continuous improvement as they should it siloed working. This is where people change aspects of a process, often theirs, without considering the knock-on impact this could have on processes further down the line or, indeed, the wider business. If changing a process in the silo, you could impact a team further down the line that was unaware of this, sometimes to some big consequences (such as a CEO not getting their bonus kind of consequences, as I witnessed first-hand). With that in mind, continuous improvement should not be done in silo – you must anticipate the knock-on.

Also read: Top 10 questions to ask in a Continuous Improvement interview

Examples of continuous improvement

When it comes to demonstrating continuous improvement, a whole article (or 10) could be written on that. There are so many examples, from across a range of industries based on a series of challenges being addressed. However, there are certain buckets which these improvements regularly fall into, and some could be seen as motivations to conduct continuous improvement in the first place. 5 general examples of continuous improvement could include:

Process improvement

With process improvement, you focus completely on analysing, reforming and improving a process, always with the aim of having a product or service delivered faster or with better quality. When it comes to delivering this approach through the continuous lens, there are a number of reasons to pursue this approach: Improved outputs, improved performance, increased capacity, increased capability, reduced time waste, reduced financial waste, removing handoffs and removing risk.

Improvement of teams

Another focus of continuous improvement can be to improve teams, continually. Our people are what make up our organizations, so investing in them on a continuous basis makes perfect sense. The way in which you can do this from a continuous improvement standpoint does not always need to be expensive, indeed many options are very cost-effective. How do we improve our teams on a continuous basis? Ways include: Upskilling them in CI tools and approaches (minimal cost), embedding a continuous improvement mindset into the teams (minimal cost), keeping a live skills matrix document (no cost), filling gaps in your current team set-up (some potential costs) and funding formal qualifications (there is a cost here). By improving your teams continuously, you don’t only improve the skills on offer to move your organization forward, you increase employee happiness, engagement and retention – all great outcomes from a continuous improvement basis.

Improvement of outputs

A focus of your continuous efforts could be the outputs of your processes. You can clearly state that you want a product to improve quality by X amount, or you want a specific service to be delivered 20% faster than it currently is. This helps focus the mind and the efforts of the continuous improvement approach, because you may not achieve those goals during the first iteration of the work you conduct, therefore you improve again and again to get there. With this approach, you can think about improving the way in which your outputs are delivered (process), focus on the issues plaguing your outputs and working backwards to address and fix them, understand what your customers want and give them that, increasing the volume of your outputs to meeting demands and improving overall quality.

Reduce time taken to do business

One of the biggest reasons for a continuous improvement approach is time – saving time, reducing the time taken to complete an activity and reinvesting that time elsewhere. Time, like our people, is the most precious thing a business can hold, and saving it, growing it and investing it into the value-adding areas of the business is critical. When it comes to this approach, you can deliver continuous improvement to ensure: it takes less time to deliver the agreed outputs, you can remove people/hand-offs from the process, processes are as streamlined as possible, technology infuses seamlessly with the process and team, each step takes a little less time each time and the product gets to market quicker.

Reducing cost of doing business

As well as saving time, continuous improvement can be deployed to save money. This will often be completed on a long-term footing, with continuous improvements again and again in different parts of the business, process or team to save money incrementally. This approach can put your finances on a stable and sustainable footing and helps reduce risk vastly by avoiding any cliff-edge decisions to save big amounts of money today, but not thinking through the consequences of such decisions. With this approach, you can deliver continuous improvement to ensure: a lower cost of doing business, better contract negotiations (lower longer-term costs) less staff being required / less hiring, reduced use of contractors, better quality equipment (less costs to fix) and more money to reinvest back into staff and automation.

Additional examples of continuous improvement exist include:

- Building in control measures to an operation

- Delivery of improvement projects on a rolling basis

- Improving the physical and digital working environment

- Reviewing and embedding SLAs & KPIs into the business

- Improving data availability and quality

- Embedding a cultural change

- Improving customer and employee satisfaction.

The process of delivering continuous improvement

When it comes to delivering process improvement, there are a range of methods and approaches you can follow. These approaches often have some form of process you need to run through to deliver your anticipated outputs, and they will differ depending on the approach, the expected outcome, size and scale of the project, industry etc. However, there is a standard process that sits under all of these approaches, a way of thinking that must be embedded into the initiative each and every time. There are 6 steps, so let’s explore them now.

Step: 1 – Understand motivations

The first action you should take is to understand your motivations. Identifying the need for continuous improvement does not just come out of thin air – there will be a reason for this. Whether it is to solve a short or long-term problem, because the organisation has embedded the approach into their new company strategy or the culture/mindset of the organisation needs a shake-up, there will be a reason. To understand what these motivations are, to get them clear and to be able to adequately explain them to leaders, there are 3 key questions that you want answered:

Question 1: What is the current situation?

Here you want to know exactly what is currently happening in the business to warrant such an initiative. Are you seeing something specific bubbling up in the organisation that warrants a change? Are you seeing issues in one part of the business or several? Is it the case that new management has embedded this approach into their strategy, and indeed nothing is wrong? You want to state clearly and concisely here. For example: Over the past 6 months, we have seen a noticeable increase in staff turnover. Exit interviews have indicated poor management, a toxic culture and a lack of development opportunities as some of the main reasons for this increased turnover. Here, you are backing it up with data and are clear about your reasons.

Outside of company strategy, motivators here could include employee or client turnover, employee or client satisfaction, culture, reducing errors, risks and issues, tackling waste, improving performance, quality and data, to name but a few.

Question 2: What do you want to achieve?

Being clear on your goals is extremely important when it comes to continuous improvement, as this can help frame your approach and keep you focused on that end goal. The type of goal you will have in mind could go one of two ways (or both in some circumstances). You are either trying to right the wrongs of the current situation you find yourself in OR you are seeking to realise the opportunities that exist within your business and the wider market. An example of a good achievement statement would be:

Our aims/goals for this initiative are:

- Reverse the trend in employee turnover witnessed in the previous 6 months.

- Improve management practices.

- Embed a new culture.

- Improve employee access to development opportunities.

These goals being realised will enable us to restore stability, upskill the team to deliver continuous improvement and improve morale. This is a good example as you are tying the goals to the impacts you are currently seeing, have identified the overall impact on the business and have looped back to the why.

Goals could include reducing employee and client turnover, improving employee and client satisfaction, reducing errors, issues and risk, reducing manual processes, increasing opportunities for automation, building new processes, and making space for new business, to name but a few.

Question 3: Are there any metrics?

Having some metrics to back up the problem, the goals and the approach is really important, especially to get buy-in from wider stakeholders and to validate what you say needs addressing. It may be the case that you need to get some sort of funding for this initiative, or need to have resources allocated to the work which could impact their business-as-usual delivery. Whichever it is, being able to show the return on investment of the work being conducted will be really important here.

To frame this in the right way, you can take your initial current state statement and your achievement statement and add in your metrics. For example: Over the past 6 months, we have seen a noticeable increase in staff turnover. The long-term average has been a 10% annual turnover rate, with this now at 40%. Exit interviews have indicated poor management (80%), a toxic culture (75%) and a lack of development opportunities (60%) as some of the main reasons for this increased turnover.

Our aims/goals for this initiative are:

- Reduce employee turnover from 40% to the longer-term average of 10% within 6 months.

- Improve management practices.

- Embed a new culture.

- Improve employee access to development opportunities.

These goals being realised will enable us to restore stability, upskill the team to deliver CI and improve morale. Here, any numbers, data or metrics you can include will be a benefit. This can include what you want to reduce the figure from and to (or increase it from and to).

Step: 2 – Plan out your approach

Once you are clear on your motivations, your goals and your why, you can now plan out your approach. This is where you want to plan out exactly how you are going to deliver the work you want to, not the what. To do this, you can explore some of the methodologies that are out there, tried and tested, ready for you to use. These could include Lean Six Sigma, the Theory of Constraints, the Plan Do Check Act or Total Quality Management. To decide which one(s) to use, you can see how your motivations, goals, timeframe and approach stack up against these.

Once you have decided which approach you are going to take (if you are going to take one) you can then identify 4 key aspects of your approach.

- What tools are you planning to use? It is good to know this early on so you can map into your project plan or timeline which tools, where and when they are happening and how much time they will take. This also helps with resource planning.

- How will we structure this? Here you want to understand how you will run this initiative. Is it going to be in stages? If so, what are they? How are you dividing up deliverables and time? If you take a Lean Six Sigma approach, are you sticking with the define, measure, analyse, improve, control approach?

- What are our resource requirements? Here you need to start fleshing out exactly who you need in your initiative/project team and for how long. Do you need a Project Manager? A Business Analyst? Change Management support? How many hours a week will your SMEs have to give up to attend workshops and share knowledge?

- What is our timeframe? It also helps at this stage to be clear and open about the timeframe linked to this initiative. How much time do you want to dedicate to each part of the initiative? How quickly do you want to see the benefits realised? The best way to approach the timeframe question is to map out each stage of the initiative and how much time you are allocating to each one.

Once you have thought through and mapped out these 4 key areas, your approach should be clear and ready to initiate.

Step: 3 – Initiate the plan

Once planned out, you can initiate your plan and your approach. However, before you can do this, there are some steps you want to take to ensure a successful initiation. You want to avoid just launching without thinking through how you are going to do this, as you want to consider the who, the how, the what, the when etc. when it comes to communicating out your launch. There are 6 key considerations to think about ahead of and as you are initiating your plan:

- Have a complete plan. Ensure, as you are launching your initiative, your plan is complete. This will be seen by many stakeholders and maybe some senior leaders of the business, so you need to ensure it is complete. This instils confidence but also stops the risk of having to pause work later down the line to continue the build-out of your plan.

- Communicate out. Once the plan is complete, you then need to both communicate that it is complete and will soon be initiated. You always want to send it / show it / make it available to those people who need to see it i.e. leaders who have signed off on the work and the immediate project team. Allowing them to see the plan instils confidence that you have thought through all that needs to be completed and delivery can start in earnest.

- Build the team. As you were planning out your approach, you would have thought about resources – what resource you need, what resource is available and for how long you will require it. Now you are in a position to reach out to those who will be involved and let them know expectations, responsibilities, timeframes etc. Some of these conversations may have already happened with their line managers, but now you can provide more detail, including on the initiative as a whole.

- Schedule the meetings. It is also a perfect time to schedule the meetings you are going to conduct, ahead of time. These meetings will include your weekly project meetings, status updates, feedback presentations to leaders, and workshops (if possible). This is a good way to set people’s expectations around their commitments early so no shocks arise later which causes concern/complaints.

- Build out the status update (and other supporting templates). Make sure you leave this stage with the relevant templates built. This will include your status update which will go out on a regular basis. This is important to have ready and going out from day 1 as it sets the tone right for the type of communication people will be receiving from this initiative, sets a consistent standard to adhere to and enables you to get feedback on what people may want to be included in it.

- Wrap up initiating activities. To close this stage out, you simply need to tie up any loose ends. This means ensuring your Communication and Stakeholder Plans are complete, and your Project Charter has been finalised and signed off. Ensure all project governance is complete and ready for launch.

Step: 4 – Deploy the activities

Now is the time to deploy the initiative activities in full. To run this initiative, you will have some form of project plan which your Project Manager or Lead will be running. This plan will include a breakdown of all of the key activities for the work to come, key deliverables, owners of these, timeframes, deadlines etc. This plan will be central to the project team meetings, where you will check on progress and monitor where you are on key deliverables.

To ensure activities are being delivered successfully, you will monitor them to ensure:

- They’re being delivered on time and on budget

- The project has and continues to maintain effective communication

- Each activity has clear owners

- Regular check-ins are happening and you have an effective way to remove blockers

This last one is particularly important as project meetings will be in place to report blockers, but this is only half the job. You will need to ensure you have a good escalation route to ensure blockers can be addressed swiftly.

Step: 5 – Deploy the solutions

At this stage, you would have worked through many of the activities in the initiative. These would have included engaging with stakeholders, conducting voice of the customer/business exercises, running root cause analysis workshops, mapping your processes etc. A lot of work would have been conducted up to this point. The purpose of much of this work is to get us to here – the ability to identify potential, choose actual and deploy your chosen solutions. Heading into this type of initiative, it is really important to ensure you don’t jump to conclusions, believing that the solution is X. Much of the work that would now have been completed has got us to a point where we can confidently choose and deploy our solutions. There are 4 key steps here:

- Identify potential solutions. This will involve running a number of workshops to determine the potential solutions that are available. These potential solutions will be a whole range of ideas, put forward by people involved in the process in question. At this stage, no ideas should be off the table, and all voices must be heard.

- Identify the chosen solutions. Once you have your full range of potential solutions, you can start to sift through this and narrow down your options. At this stage, you will start to discuss these solutions in terms of certain criteria, such as the cost of deployment, the time taken to implement, their synergy with the initiative goals etc. As you work through these criteria, you will have less and less potential solutions in front of you and eventually, you finally choose a few.

- Plan the deployment. Now is the time to conduct yet more planning! Here, you will plan for the deployment of your chosen solutions. This will often be done through an Implementation Plan, which will detail the solutions, the timeframe over which they will be deployed, who owns this activity, what are the risks and concerns etc. You need to plan for as smooth a delivery of solution as possible.

- Deploy the solutions. The final step is when you actually deliver your chosen solutions. Here, the Implementation Plan is deployed in full, and tracked over time to ensure the implementation of the solutions remains on track and is successful. At the end of this step, all solutions would have been chosen, planned for, tested, deployed and LIVE in the business.

Step: 6 – Control & repeat

The final step in the continuous improvement process is for you to control the changes and repeat. In terms of controlling the changes, here you need to identify the right control measures to put in place to ensure the changes you have made last the test of time. These controls are to ensure the issues and problems seen before do not occur again and that if they do, you can react better this time around to avoid a wider issue arising from this.

Controls here could include giving new processes an owner who will be held accountable for ensuring they continue to deliver the outputs expected of it. You could build control charts to monitor the stability and capability of the process, monitor changes in the outputs, the time taken to deliver them or quality. Other controls could include checks, peer reviews, and automated bots conducting data quality checks. All of these controls are aimed at ensuring the changes stick because the last thing you want is for your initiative to finish, you walk away and everything that was just done starts to unravel.

In terms of repeating, this is where the true continuous improvement nature of this process comes to life. Now you have seen the benefits, and have reaped the rewards of what you have done, you will now not only be in a position to repeat these efforts, but you’ll be itching to. The repeating of this effort does not necessarily mean repeating everything like for like. You can repeat some of the tools, you can focus on improving certain aspects again, tightening up on KPIs and the performance of certain metrics. You can tackle whole new processes or problems that are now on your radar, learning the lessons of what you have just done and applying them to new areas.

When it comes to repeat – you don’t need to repeat like for like, you just need to ensure you are improving your organisation, continuously and using the tried and tested methods and tools available to you. And the best thing here is when you’ve done it once, twice, three times, it gets easier and easier and can be deployed faster and faster, thus accelerating your continuous improvement journey.

Also read: What Is a Continuous Improvement Consultant? – Everything you need to know about a CI consultant.

Conclusion

Continuous improvement, when delivered correctly using the right methods and tools, is a truly powerful approach. It can deliver outstanding results for organisations that truly embrace it, upskill their teams in it and embed the mindset of change across their operations. If you want to harness the genuine benefits of continuous improvement, infuse the approach into the fabric of everything you do, from day-to-day activities right up to the wider business strategy, from those delivering the processes right up the board. Only then will you really see just how wonderful continuous improvement can really be?