Table of Contents

I. Why Setup Time Is Killing You

Setup time is the time your machine is doing nothing. No cutting, no shaping, no packing—just sitting there while your team changes a tool, adjusts a mold, or calibrates the system. That’s time you’re paying for, but not earning from.

Now multiply that across several machines and shifts.

Let’s say a factory changes setups 6 times a day. Each changeover takes 45 minutes. That’s 4.5 hours of dead time—every single day. Over a year, that’s thousands of hours lost. No production. Just waiting.

“Time is the most valuable thing a man can spend.” – Theophrastus

And you’re spending it—poorly—if you’re not fixing your setup process.

II. What Is SMED? (Plain English, No Jargon)

SMED stands for Single-Minute Exchange of Die.

It’s a method to cut machine setup times to under 10 minutes. The goal? Get your machines back in action—fast.

It was developed by Shigeo Shingo, an industrial engineer working with Toyota in the 1970s. Back then, it took them up to 4 hours to change a die on a press machine.

After applying SMED?

They dropped it to 3 minutes. No magic. Just smart process tweaks.

That changed everything. Less downtime. Smaller batch sizes. More flexibility. And a major competitive edge.

III. Why SMED Matters

Let’s keep it simple: every minute your machine isn’t running is money out the window.

Here’s what SMED gives you:

- More production in the same time.

- Smaller batches, so less waste and more variety.

- Faster delivery because setups don’t block the flow.

- Lower inventory, which means lower storage costs.

And the impact is real. According to industry data, U.S. manufacturers lose 20–30% of productive time to setup and changeovers.

That’s not a small leak. That’s a flood.

With SMED, you plug it—and turn downtime into profit.

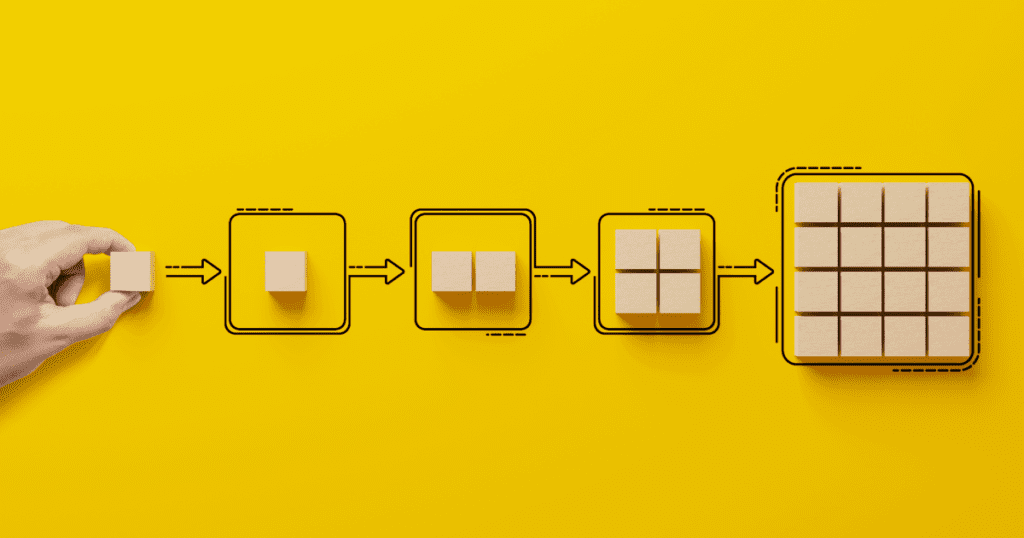

IV. Internal vs. External Setup: The Big Idea

This is the heart of SMED.

- Internal setup = tasks that can only be done when the machine is off.

Example: changing a mold, installing a die, rewiring a part. - External setup = tasks that can be done while the machine is still running.

Example: gathering tools, prepping materials, pre-heating the next mold.

The Goal:

Turn as much internal into external as possible.

Why? Because every second the machine is off is costing you. The more work you can shift outside the downtime window, the shorter that window gets.

V. The 4-Step SMED Process (With Examples)

1. Observe & Record

Start by watching the current setup process. Don’t guess. Record everything.

Example: A worker walks 50 meters to fetch a wrench during every changeover. That’s 5 minutes gone—just walking.

Lesson: That’s not a setup problem. That’s a layout problem.

2. Separate Internal from External

Go through the list of tasks. Which ones need the machine to be off? Which don’t?

Example: Preheating a tool before the current job ends. That’s external. Do it ahead.

Lesson: Treat every second of machine downtime like a fire—put it out fast.

3. Convert Internal to External

Ask: Can any of the internal tasks be reworked to happen before or after the machine stops?

Example: Instead of setting gauges during downtime, preset them in advance.

Example: Pre-assemble parts while the current batch finishes.

Lesson: Don’t wait for a red light to start working.

4. Streamline Everything

Now optimize what’s left.

Examples:

- Replace bolts with quick clamps.

- Use preset guides instead of measuring every time.

- Standardize tools and layouts to eliminate hunting.

Lesson: Speed doesn’t come from rushing—it comes from removing friction.

This process works in any industry: manufacturing, food production, packaging—even healthcare or hospitality.

VI. Case Study: How SMED Saved Thousands

One mid-sized packaging company had a serious bottleneck: each machine changeover took 90 minutes. That meant fewer batches, longer lead times, and lots of wasted labor.

They applied SMED—step by step.

- Mapped the setup process.

- Separated tasks.

- Prepped tools ahead of time.

- Swapped bolts for quick-release clamps.

Result: Setup time dropped from 90 minutes to just 7.

That unlocked:

- 25% more machine uptime

- 15% increase in overall output

“It was like getting a new machine without buying one.” – Plant Manager

No extra machines. No new hires. Just smarter setups.

VII. Common Mistakes (and How to Dodge Them)

Even simple systems like SMED can go sideways if rushed or misunderstood. Here’s what to avoid:

- Overcomplicating it – SMED is about removing steps, not adding layers.

- Skipping the observation stage – Don’t guess. Watch real setups. Every second counts.

- Ignoring operator feedback – The people on the floor know what really slows them down.

- Not training the team – Everyone needs to know the new process. No tribal knowledge, no gaps.

VIII. Tools That Help

You don’t need fancy tech. Start with basics:

- Visual setup sheets – Step-by-step pictures reduce confusion and speed up training.

- Video analysis – Record setups, review them, find waste.

- 5S organization – If tools are where they should be, time isn’t wasted finding them.

- Stopwatch + clipboard – Still the most underrated setup tool in the game.

Small tools. Big wins.

IX. Wrap-Up: Fast Setups = Fast Profits

SMED isn’t just for auto giants or mega factories. Any team with repeatable setups can use it. Whether you’re pressing metal, baking cookies, or packing boxes—setup time is costing you.

And cutting that time?

That’s free capacity.

Final stat to remember: If you reduce every changeover by just 10 minutes, and you do 4 setups a day, that’s 40 minutes a day. Over a year? You save over 160 hours.

That’s two extra weeks of production—without hiring, buying, or expanding.

SMED = more speed, less waste, bigger margins.

Done right, it pays for itself fast.

Lean Management | Certification Course

Buy Now for $9.99

Udemy prices may vary depending on applied coupons and promotional events.

- 🧑🏫 61 lectures

- ⌚ 3h 51m total length

- 🗃️ 13 downloadable resource

- 📜 Certificate of completion

- 👩🎓 12,657 students

- ⭐ 4.7 rating by 511 students