Table of Contents

When it comes to Lean Six Sigma, the ultimate goal is to achieve a Six Sigma level of performance. When a process, operation or company reaches this level, it means they have become better than perfect. They can deliver products, services and outputs seamlessly with no errors, issues, defects, problems, complaints etc. They are slick, lean, efficient, effective, and productive. They are what everyone aspires to have.

However, getting to that level is extremely difficult, more than extremely difficult. That is why, when it comes to Lean Six Sigma, organizations often use the level as an aspiration, a goal, or a desire, knowing they may never actually achieve it. The win comes in the effort to continually get better in the pursuit of that goal. If you can never quite achieve it, you will continually improve to try and get there, never stopping, always getting better.

There is, however, one process and one industry that has indeed achieved a Six Sigma level of success. That is the airline/aviation industry. This is one industry that has strived to get better and better, safer and safer, year after year and has indeed achieved the Six Sigma level.

What is the Six Sigma level?

Before exploring the airline/aviation example in more detail, let us first establish what the Six Sigma level actually is. In effect, it is a level set relating to defects. If one achieves under a certain number of defects for every 1 million transactions they make, they hit a Sigma level (4, 5, 6 etc.). The closer to 6 this sigma level is, the better the process is performing. The calculation here is as follows:

How many units have you processed? This refers to how many transactions or activities have been conducted.

How many defects do you have? A definition of a defect is a transaction or activity which has gone wrong – it is defective.

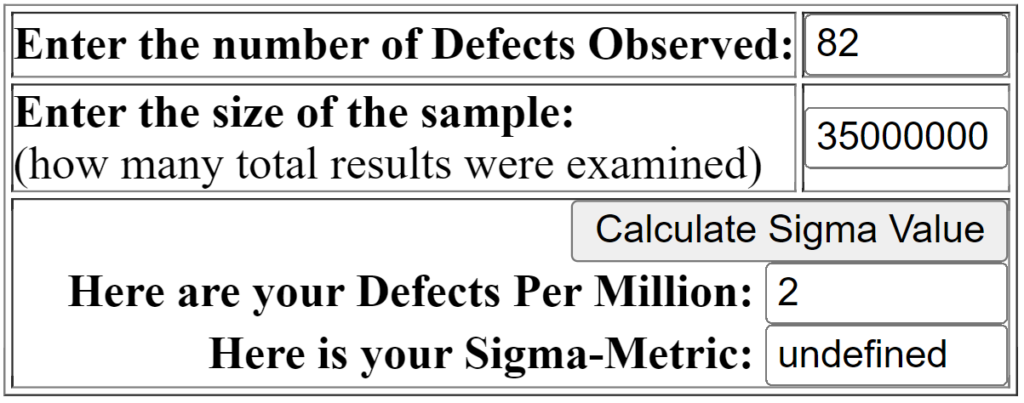

Add this into a Six Sigma calculator such as the one here to work out your defects per million and your Sigma level. (Don’t worry about the complicated calculation that sits behind it, the calculators do all of that work for you).

Let us look at an example.

Units processed: 10,000 calls handled in a contact centre

Number of defects: 450 defective calls (defined in whichever way they deem fit)

Defects per million opportunities (DPMO): 45,000

Sigma Level: 3.2

Effectively, what this means is that out of one million calls in the contact centre made, 45,000 of these will be defective in some way. To achieve the Six Sigma Level, you need to be seeing 3.4 defects per million or less – therefore this process is WAY off.

Therefore, if you want to achieve a Six Sigma level, you need to be seeing only one defect in every 294,117 transactions. If you think about how many data errors, human errors, system errors etc. we see on a daily basis (with much of this work becoming BAU) achieving Six Sigma is near impossible.

A process that performs at a Six Sigma level: The airline/aviation industry

Even though achieving the Six Sigma level is infinitely difficult, it has been done. Given the sheer amount of risk there is within the aviation industry, the number of lives that could be lost through one plane accident and the health and safety concerns at every step of the way, it is probably no shock that this industry has achieved the Six Sigma level.

Let’s look at the figures.

In 2023, there were a total of 35 million flights around the world, at the same time there were 82 accidents involving some form of aviation. When we put this information into the Six Sigma calculator, we were told the following:

Units processed: 35,000,000 flights

Number of defects: 82

Defects per million opportunities (DPMO): 2

Sigma Level: 6

This means that in 2023, for every 500,000 flights, there was 1 accident or 2 per million – therefore this industry is at the Six Sigma level.

To get there, the airline industry deployed Lean Six Sigma at many stages of the process. From the designing of the planes to the manufacturing of the bodies, the compiling of the health and safety standards to the takeoff and land process, everything was meticulously handled. They have also run many of their projects through the DMAIC Lean Six Sigma project management framework.

The industry was also very good at learning from mistakes and defects gone by. When there was an accident, lessons were learned and new procedures were applied throughout the global industry. Knowledge is always shared across the international bodies and when changes are proposed, they are rigorously scrutinized and tested. All of these practices are commonplace within the world of Six Sigma and will help you maintain your Six Sigma level once you achieve it.

Conclusion

If you are looking to achieve a Six Sigma level of quality within your operations, look at those that have already done it. The aviation/airline industry is a great example to aspire to be like in terms of quality and performance, so read up more on this industry, how they did it and how they continue to achieve this today (rising passenger numbers and falling accident rates – that is the sweet spot!)

Find More: Lean Six Sigma Topics