Table of Contents

I. Mistakes Cost Money

In manufacturing, mistakes aren’t a rare surprise—they’re part of the daily grind.

Someone grabs the wrong part. A label gets swapped. A product ships with a missing screw. These aren’t freak accidents. They’re normal human behavior.

But those tiny mistakes? They cost big.

Real-world example: One factory mislabels allergy info on a food package. Result? A nationwide recall, lost revenue, and legal headaches.

“An ounce of prevention is worth a pound of cure.” – Benjamin Franklin

That’s where Poka-Yoke comes in. It’s not about working harder. It’s about designing systems that make mistakes hard to make.

II. What Is Poka-Yoke? (Plain and Simple)

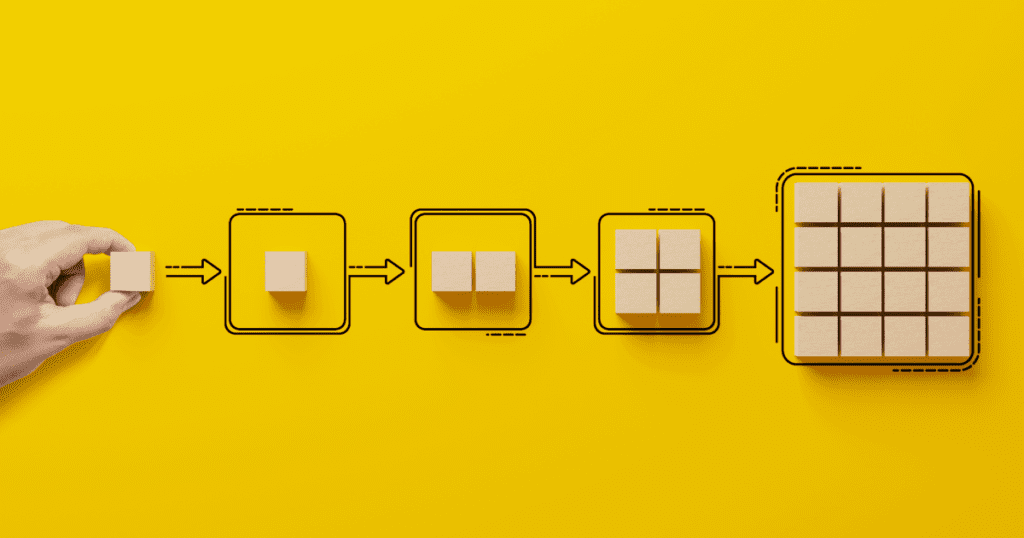

Poka-Yoke (pronounced poh-kah yoh-keh) is Japanese for mistake-proofing.

It’s a method that makes it impossible, or at least very difficult, to do something the wrong way.

Think of it as built-in common sense.

It was created by Shigeo Shingo at Toyota in the 1960s. His insight? Don’t just fix errors—design systems that don’t allow them in the first place.

Poka-Yoke doesn’t replace people. It supports them—by removing chances to mess up.

III. Why Poka-Yoke Works

Let’s keep it simple: humans make mistakes. A lot of them.

Studies show that 60–80% of quality issues in manufacturing are due to human error.

Poka-Yoke flips that.

It works because:

- It stops errors before they become defects.

- It saves money—less rework, fewer returns, no expensive recalls.

- It boosts safety—no more guessing, no risky steps.

- It’s fast, simple, and cheap to implement.

In short, Poka-Yoke takes the pressure off people—and puts smart design to work.

IV. Two Types of Poka-Yoke

Poka-Yoke isn’t one-size-fits-all. There are two main flavors—each stopping mistakes in a different way.

1. Prevention Poka-Yoke

This one stops the mistake from happening at all.

It’s built into the process so doing the wrong thing just isn’t possible.

Example:

A USB plug only goes in one way. You don’t have to think. You can’t get it wrong.

Result: No errors. No do-overs.

2. Detection Poka-Yoke

This one catches the mistake after it happens—but before it causes damage.

It throws a flag so the issue gets fixed on the spot.

Example:

A machine beeps if a part isn’t loaded right or something is missing.

Result: Mistake caught early. Defect prevented.

V. Common Poka-Yoke Techniques (With Examples)

You don’t need to reinvent the wheel. These proven methods work across industries:

✅ Checklists

Used in aviation, surgery, and factories.

Why: Simple steps get missed all the time. Checklists make sure they don’t.

📡 Sensors

Detect if something is missing, misaligned, or in the wrong spot.

Example: A conveyor stops if no product is detected before sealing.

🔷 Shape Matching

Parts are designed to fit only one way—no guesswork.

Example: SIM cards. Wrong orientation? Doesn’t fit.

🎨 Color Coding

Label wires, tools, and containers by color.

Example: Red bin for defects, green for approved parts.

🔒 Physical Blocks

A system won’t run unless all conditions are right.

Example: Machine won’t start unless guards are closed and parts are in place.

All simple. All powerful. All mistake-proof.

VI. Real-World Wins: Poka-Yoke in Action

🍴 Food Industry Fix

A snack company kept sealing empty pouches due to feeding issues.

They installed a sensor to detect contents before sealing.

Result: Defects dropped 95%. No more wasted film. No more angry customers.

🚗 Automotive Precision

A car parts manufacturer had workers installing bolts into multiple holes. Mistakes were common.

They introduced custom jigs—bolts only fit in the right hole.

Result: Zero installation errors. No extra training needed. Just better design.

VII. Where Poka-Yoke Fails (And How to Fix It)

Even a good idea can flop if it’s done wrong. Here’s what makes Poka-Yoke break down:

- Overcomplicating the design

If it’s too complex, no one uses it—or worse, they work around it. - Making it optional

A mistake-proofing tool that can be bypassed isn’t mistake-proof. - Ignoring worker feedback

The people using the system daily know what works and what doesn’t.

✅ Fix it fast:

- Keep it simple.

- Make it automatic.

- Design it so it’s hard to miss and hard to mess up.

If it takes more than 10 seconds to explain, it’s probably too complicated.

VIII. Poka-Yoke Beyond the Factory

Poka-Yoke isn’t just for engineers. You see it every day, all around you:

- Microwave ovens won’t run unless the door is closed.

- Credit cards only insert one way—wrong angle? No read.

- ATMs won’t give you cash until you remove your card.

Mistake-proofing is everywhere because it works.

It keeps people safe. It saves companies money. And it reduces stress for everyone.

IX. Wrap-Up: Small Fixes, Big Results

Poka-Yoke is not about expensive tech. It’s about clever, low-cost fixes that make mistakes almost impossible.

And it works everywhere:

- On the factory floor.

- In hospital checklists.

- In commercial kitchens.

- Even in your office software.

Final stat: Companies that apply Poka-Yoke effectively often see defect rates drop by 50% or more within months.

Small changes. Huge payoff.

Mistakes will happen—but with Poka-Yoke, they won’t stick around long.