Table of Contents

When it comes to future-proofing your business, your organizational prowess and your operational performance, nothing can do this better than deploying sound, well-renowned tried and tested business improvement techniques. There are a range of business improvement techniques available to you, all doing something different, delivering varying outputs and being deployed to impact a range of different metrics. However, fundamentally, business improvement techniques are there to do one key thing – to improve your business, whatever this looks like to you.

Business improvement techniques can fall into a range of different fields. They can be related to technology, systems, people, processes, procedures, products, services, delivery models, org structures, quality assurance etc. The list really can go on. With that in mind, the array of business improvement techniques to choose from will continue to evolve and get longer over time, as businesses grow, experiment and innovate. Many of the business improvement techniques available have been around for many many years, tried and tested and successfully delivered in manufacturing or production environments originally, and more recently in services.

7 Business Improvement Techniques

In this article, we are going to run through a further 7 business improvement techniques (we have identified other previously found here). These techniques covered here are those that have been successfully deployed by organizations for a range of different reasons, with the business improvement aspect tied heavily to them. Whatever your aim with your improvement journey, these business improvement techniques will help you get there faster, more confidently and more successfully.

1. Train and develop your people

Training and developing the staff within your organization is one of those business improvement techniques that absolutely lasts the test of time. It is one of those approaches which can be deployed over a short or longer period of time. It can deliver instant benefits and longer-term benefits. It can embedded into goals set for short-term gain or longer-term strategic goals also. The fundamental point here is to just get started.

You want to first get a sense of what your team currently looks like from a skills and qualifications perspective. This will involve you pulling together a skills matrix to look at what skills the team currently have (ranked basic, intermediate, advanced, for example) by listing out a range of skill sets you need. These can cover things like Excel, Office Suite, data analysis etc. through specific qualifications or experience in things like Project Management, Business Analysis, Change Management etc. Painting a picture of the current state of play in terms of skills is a great starting point.

Once you know the current state, you can then identify the gaps and seek to fill them. This will include building into the development goals of individual team members the training they require. This can be internal or externally given training, focusing on specific activities and skills or wider qualifications and certifications. The plans you put in place here will look at the short-term needs of the business and individual and then, the longer-term needs. This approach will significantly help in your ability to improve your business in many ways. These include not having to go external as often to hire specialists temporarily, being able to fix things as and when they arise, managing projects better, spotting and reducing risk earlier etc. All add to a better-performing operation.

2. Establish a quality/improvement training programme

Carrying on with the training business improvement techniques, you can also build out a training programme specifically aimed at deploying business improvement techniques, methodologies and approaches for the benefit of your business. These are often referred to as quality and improvement training programmes and those that enrol end up being called Quality Champions or Improvement Champions.

These programmes are specifically designed to ensure those who enrol become experts in a specific field within business improvement. Whether that be in Lean or Six Sigma, Continuous Improvement approaches, quality management and assurance etc. the idea is to build out a structured programme which individuals can move through to get these skills. As they move through, they learn a range of new practical techniques and skills that they can deploy in the business relatively quickly. They are then assigned tasks, goals and projects to see them deploy business improvement techniques naturally through the work they are doing daily.

The Quality Champion, once fully certified, will sell the vision of change within the business, will root cause problems as they arise identify fixes, and will map processes to identify waste and opportunities for improvement and deliver the change. They will run small, medium and eventually larger scale projects which help to deploy lasting change and improvement, new systems and technologies, automation and streamlining events. It will of course depend on what your organization needs, but when it comes to his type of programme, the sky really is the limit.

A word of advice here. Don’t nominate people to take part, have people put themselves forward. Those who are nominated may not want to partake, and to get the most out of this programme, you want to ensure those learning and delivering are truly passionate about change and improvement.

3. Embed workshops & improvement events into the teams

As workshops are a regular part of business improvement projects, root cause analysis exercises, quality initiatives, Lean Six Sigma projects etc. why not embed them into the working practices of your organization? These types of business improvement techniques are really simple to embed in relatively quickly. All you need to do is identify why you require one, identify who needs to be present, schedule a time, run the workshop and act on the findings.

Often, workshops like this will be to gather knowledge and information. We have a process that is currently not working as expected, therefore we are going to run a workshop to map out the process in full, conduct an analysis of the process and see what we need to do next. From the insight gathered here, an improvement project can be launched (by the team or your Quality Champions) to make changes to the process to ensure it can once again operate as expected. This kind of workshop gives you information you may otherwise not have got.

The workshops give colleagues the space to talk openly and freely, to feel more engaged with what before and to act as launching pads to a series of improvements the wider business could feel for years to come. All in all, a big win for those involved.

4. Audits on performance to be embedded

Another of our business improvement techniques is to keep on top of what is happening within your business by default. This can be done through reporting, dashboards, KPIs etc. but also it can be done through something more proactive, such as an audit.

Many organizations have now built into their calendars for audits to take place on a regular basis. Whether every month, every 3, 6 or 12 months, the audit is a way for them to understand exactly what is going on within a specific department or process. When conducting an audit, you are looking out for certain parameters. This could be along the lines of: are we hitting our targets? Are we operating within SLA? Are we achieving our KPIs? It could also refer to: are our processes producing the same amount of quality output this time around compared to when the last audit was done? Are these processes producing these products in the same amount of time? Are we seeing an increase in the cost of doing business? All of these indicators will let you know whether or not something may need looking into.

Equally, you can audit your people, your teams and even your customer responses. Are our colleagues happy? What are they telling us? Are our customers happy? What feedback are we getting from them? Are sales of those products and services in scope for this particular audit falling, remaining stable or surging ahead? Again, all of this insight will inform the business on a team, customer base or product catalogue performing well, badly or just, OK. The main benefit of conducting such audits is that they give you information – information from which you can act.

5. Utilize the 7 tools of quality in your business

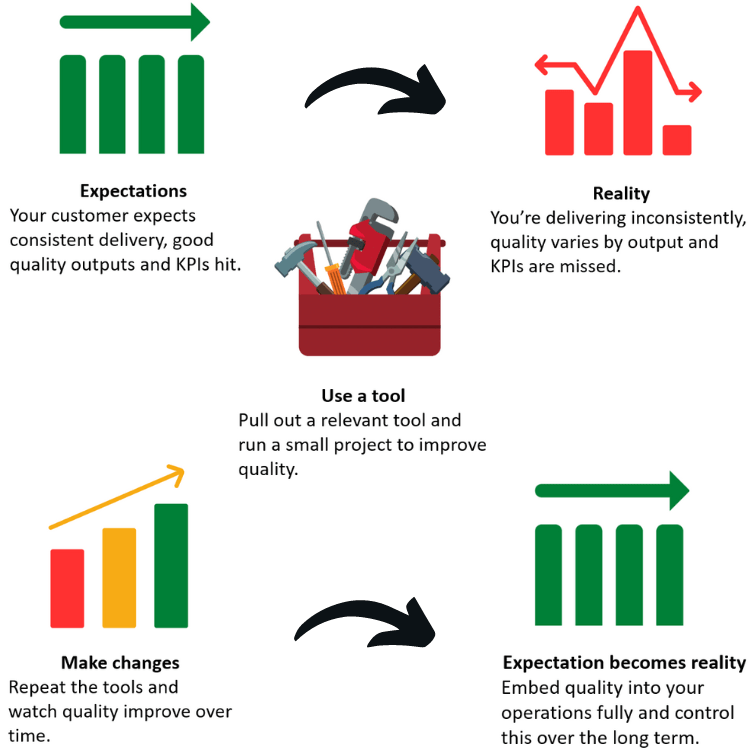

There are a range of business improvement tools available to all organizations. Whether they be to process map, improve a process, root cause a problem, solve issues, identify current state, or highlight performance, stability and capability, these tools have stuck around for many years because they are successful. These tools, initially rooted in the world of manufacturing and production, have since spread to the services industry to great effect.

These tools include a Pareto Chart, Histogram, Check Sheet, Run Chart, Fishbone Diagram, 5 Whys Diagram, and Process Map. The tools are used to help fix things that are broken, present data in more usable ways, indicate the way forward from issues experienced today and give you insight into the distribution of sales, stability of performance and current state snapshots. As with many business improvement tools, these give you insight and information that you can use to make better, more informed decisions.

You can DOWNLOAD the TEMPLATES from here. It’s FREE.

If you have a problem, use the Fishbone Diagram to identify potential causes, categorize them and solve for these causes. If you need to build out better resourcing within your teams, build out a Histogram Chart to understand the distribution of workloads over the year. If you want to understand opportunities for improvement within your processes, Process Map then and complete Run Chart analyses on them to identify opportunities and where your processes are currently being compromised. The toolkit itself is a highly functional one that can be used for all parts of your business improvement journey, so use it.

6. Build out an exhaustive business improvement plan

It goes without saying, that one of the first business improvement techniques you need to deploy is a plan for the business improvement you are searching for. Such a plan is needed from day one to help steer you from your current state (often a compromised state in need of help) to that future desired state (one of fully optimized, Lean, productive, efficient and highly effective operations). Going on this journey and getting to the promised land of total improvement is not an easy feat, and trying to do this without a fully formed plan to help get you there is a fatal flaw of so many organizations.

Firstly, think about what you want. Why are you looking to go on this journey? What is not happening today that you want to be? What is happening today that you want to stop? Being clear on your aims and your goals is vital, and the very act of building out a plan can help you with these.

Secondly, think about how you are going to get there. What does this roadmap look like? Does it involve bringing in outside help? Does it involve large-scale training and upskilling through quality and improvement training programmes? Are you going to focus on workshops, process improvement events, or Kaizen events? Are you going to follow a methodology such as Continuous Improvement, Lean Six Sigma or Quality Management?

Next, think about what you need to support you in that journey. If you are looking to train, do you need a budget to secure this? If you are looking to use certain methodologies, do you have the skills in place to do so? What time frames are you thinking about? Do you need facilitators to facilitate a series of workshops? Do you need to have access to extensive datasets or do you plan to create your own? There are a LOT of questions when it comes to building out a plan for business improvement, but once you build out your plan, answering the questions along the way, you’ll realize this is by far and away the most important of all of the business improvement techniques.

7. Survey your colleagues, customers and clients

This is one of those business improvement techniques that is about getting more insight and information to make better and more informed decisions. The data you can collect from surveys, interviews, focus groups – any form of engagement with the people inside and outside of your business is gold dust. It is largely free data, given to you willingly by those who want to see things improve for, mainly, their own benefit. They want to see their product and service offerings get better. They want to see their day jobs become more focused on the value added and less wasteful. They want to achieve more, and see more success and your customers want to buy more (often).

With that in mind, find ways to speak directly with these people. Hold regular 1:1s with your teams to understand their experiences today. Hold Town Hall events internally to let people have a forum where they can speak up. Run employee satisfaction surveys. All of these techniques give you ways to collect information you can ultimately turn into projects to improve processes, people and procedures internally.

Equally, have your Account Management teams work better with your clients. Set up regular check-ins to get their thoughts, feelings and experiences. Ask them what they would like to see from your services going forward. Utilize tools such as the Kano Analysis Diagram and Critical to Quality trees to pinpoint exactly what customer needs are both today and will be in the future. All of this insight can feed into the business and into your business improvement projects to ensure the work you are doing today is improving the experience of the business and the customer, collectively.

Lets Recap

Conclusion

When it comes to identifying business improvement techniques for your business, you really need to ask what your why is here. Are you looking for a full-scale plan? Are you looking for tools that can be deployed regularly by your team, taking pressure off of your Leaders? Are you looking for new ways to generate data and insight that you can ultimately package up into business improvement projects? Do you want to upskill and train your whole organization so that business improvement, quality and change become embedded in the company culture, in the business strategy and in the day jobs of every colleague?

Whatever your answer is will dictate what approach you need to take and the business improvement techniques you need to deploy. With that in mind, it is worth remembering that those organizations that are having the greatest success in the market today are those that are deploying business improvement techniques daily. They have embedded them into their organizational structures successfully. They have identified that change and quality is not just the job of one person or one team, but is the job of everyone, from the CEO down. If you can set up your organization to operate in this way, you are setting up your organization for success in business improvement.