Table of Contents

Business improvement techniques do not need to be those that are large in scale, cost a significant amount of money, and require a lot of resources and support to enable them to be deployed. Indeed, some of the most commonly deployed business improvement techniques are those that are light on resources required, costs involved, and disruption to the company. These business improvement techniques are simple, focused, and tried and tested. They identify exactly what needs addressing, know the route required to address it, and can alleviate any long-term effects by controlling the outcomes successfully.

These business improvement techniques are great for deploying early on in your business improvement journey but are also highly effective when embedded into the daily activities of colleagues and staff. They can be relatively simple to train out to others, to retain the knowledge required, and to sell as a solution for the problems faced by Leaders in the company.

Business improvement techniques successful organizations are deploying

Given the fact that business improvement journeys can be hard, arduous, and take some time, using business improvement techniques such as the ones we set out in this article softens the blow, alleviates some of this stress, and makes deploying change far more comfortable. Some of these business improvement techniques can be seen as quick wins or, as some people say (to the discomfort of others!) low-hanging fruit.

They are business improvement techniques that remove problems, issues, bottlenecks, defects, waste, waiting, etc. quickly. They impact the jobs of those working in the processes positively, they’re visual (I can physically see the process taking less time) and they can lead to solid ripple effects across the business, impacting both the wider operation and customers alike. When it comes to these business improvement techniques, if you want quick delivery and quick turnaround of your goals, these are the right options for you.

1. Embed controls into every process

Controlling the activities conducted and therefore the performance produced is the first of our business improvement techniques. When people deliver their work, the steps within a process, and the activities surrounding the delivery of products and services, often they do so without really thinking. The aim is to deliver in the way laid out in the training materials, and this is what I will do. This approach is absolutely fine, but it is open to risk.

As with any process, new, reformed, or old, risk can, over time, increase as the market within which we operate evolves, the teams delivering the work change and the pressures for more outputs grow. This therefore means the work we do requires control. We need to control the activities, the way we do work, the products delivered, and the quality of our outputs. We need to ensure risk is reduced, the change of errors or defects diminishes and we can deploy work unimpeded and to customer expectations.

To do this, you need to identify what controls you can put around the activities. Common ones include peer reviewing work, building automated checks to systems, and reporting back on performance so Leaders can see if there is any risk growing. You can also build out Risk Registers which keep a score of the risk levels of your process, you can build out Run Charts which track the stability and performance of your processes. All of these are ways to either keep an eye on performance, enabling you to swoop in and fix problems as and when they arise, or act as genuine controls that reduce the chance of these problems ever occurring in the first place.

2. Build out Control Plans for every process

Very much linked to the business improvement techniques as laid out in option 1, as well as simply putting controls in place, you must control the controls. This can be done by building out a Control Plan. A Control Plan is a great way for you to identify the risks/activities within a process, identify the controls you are going to put in place to mitigate any risk and identify who is responsible for this. It is a great way to hold those identified as the control owners to account, ensuring that if anything should begin to go awry in that process, the owner will flag or address this right away.

The Control Plan can also be used to identify the parameters of success for that control (for example, if the performance of said activity falls out of these two metrics such as 2 minutes or 10 minutes, then this indicates we have increased instability in the process, therefore we have to act). They can include when the owner should conduct a review of the controls to ensure they are working and can even indicate secondary controls to control the first control and delegates who take on responsibility for these controls when the main owner is out. Of the business improvement techniques discussed in this article, this one will require the most amount of agreement and wider discussion amongst interested stakeholders.

3. Bear down on rework in your processes/operations

This is one of those business improvement techniques people at every level of the business can easily deploy. A rework loop is something that builds into a process over time when something goes wrong. When something goes right the first time, every time, you don’t get rework loops. When something goes wrong, you have to go back and do it again. If you repeat this process and it goes wrong again, you have to go back and do it…again. This indicates you are stuck in a rework loop, going back and forth between two points in a process because something is not working.

To fix this, you need to remove this rework loop. To remove the loop, you need to find what is going wrong, and why it is going wrong, and deliver a solution to fix this. This of course involves some upfront work to diagnose the problem, identify the root cause, find a solution, and deliver this. However, this work is worth the time saved by not having one or multiple colleagues getting stuck in the same rework loop time and time again. That is why this is one of those business improvement techniques that can be deployed as part of daily activities by your staff.

It simply requires you to send out a directive to the business that says – “any time you find yourself in a rework looping, repeating the same thing again and again because something has gone wrong, don’t just accept it. Report it. Solution for it. Fix it”. This not only sees rework loops being removed from your processes, but it also sees greater engagement from your colleagues, an acknowledgement that the business trusts their judgment, and an upskilling of their abilities. These facts alone help to expand the ripple effects of business improvement techniques such as this one.

4. Open up the channels of best practice, knowledge, and lessons learned sharing

Open and transparent organizations, open and transparent communication channels, and open and transparent colleagues are the fundamental building blocks to the successful delivery of change and evolution within a company. This is one of those business improvement techniques that acknowledges this.

Within your organization, you will have projects ongoing, programs of work being delivered, and initiatives launching nearly every day. As these happen, they are collecting information, unknowingly. This information comes in the form of lessons learned. How did these launch successfully? What forethought was put in this time that was missing prior? Why were some of these approaches more successful than others? What can we learn today so the next initiative is more successful?

All of this insight is such a value add to your organizational success, but so few companies utilize it well. To do this, open up dialogue between the different initiatives. Launch lesson-learned logs for information to go into. Hold Town Halls where successful projects delivered are discussed, not just the results but how they got there. Share more project meetings and have more 1:1s with those who require it. Share templates, successful Project Plan documentation, expert information, etc. all to ensure the other projects ongoing in the firm can learn from the successes of those who have gone before it.

This approach wraps up several business improvement techniques including more open and transparent communication, better sharing of best practices, and better sharing of lessons learned and knowledge gathered along the way.

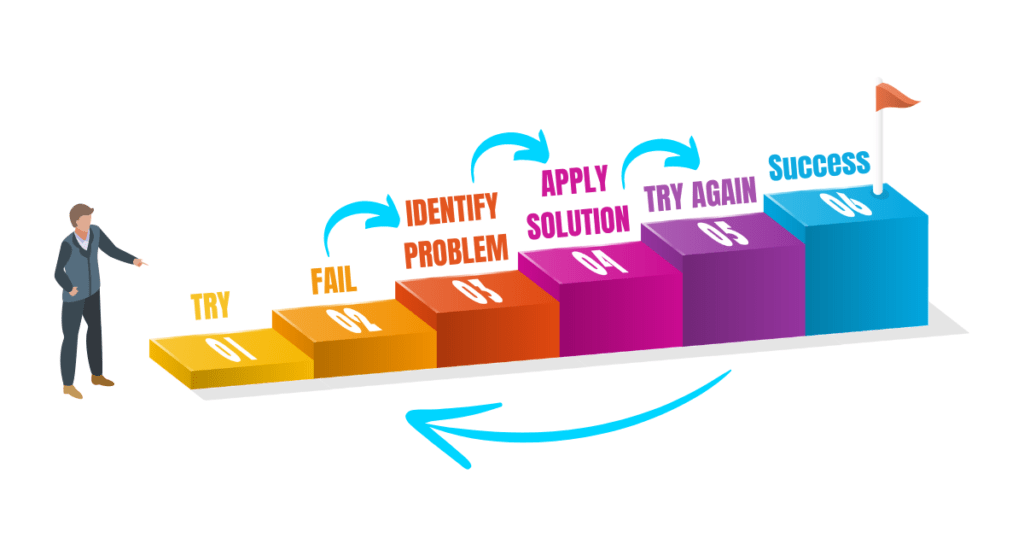

5. Set stricter parameters around the root causing of problems

Another of the business improvement techniques that sits around the idea of mindset and behavioural shifts is that of root cause analysis. Issues, problems, and defects occurring are some of those facts of life when it comes to delivering processes within a company, and this is fine. However, some companies have become too complacent with the errors they are seeing, building them into the process and highlighting in training materials that “the system may produce X amount of errors here. If so, do X”. This is a huge admission of failure and giving up on something which could probably be fixed if a little attention was paid.

With that said, one way to tackle this is to shift the mindset and ensure root cause analysis is at the heart of your colleagues’ response to issues. This could involve some light touch training on root cause analysis tools such as the Fishbone Diagram, Drill Down Tool, or 5 Whys. You can add into their performance goals targets around the identifying and fixing of problems within their day jobs, the impact of this in terms of effects and harm reduced, and potentially money saved.

You could also set wider process or departmental targets which state that, “currently this process is operating with a defect rate of 4%. The aim for the department running this process is to cut this in half to 2% in the coming 6 months”. Equally, if you provide products to customers you could state, “Currently, we have a returns rate on our products of 20%. We are this year targeting a returns rate of no more than 15%.” All this does is focus the mind and the efforts of the teams in question to root cause problems as they arise, be proactive at hitting targets set and ensure the risk of any potential problems arising is controlled as much as possible. All of these business improvement techniques will ripple across the wider process/department positively.

6. Instil Lean principles into the heart of the business strategy

Lean is by far the most well-known and most popular business improvement technique out there. It is a methodology, an approach, a series of tools, a mindset, a project management delivery vehicle, a set of principles, etc. Lean thinking is all about finding ways to ensure your processes are operating as effectively, efficiently, and productively as possible. It looks for ways to reduce waste, waiting time, defects, issues, bottlenecks, rework loos, backlogs, etc. It focuses on finding ways to get you from one state (often a compromised state) to a newer, better state in the future.

Given this approach has such good principles at its heart, placing them at the heart of your business strategy is key. This would see you making decisions through a Lean lens. When we are launching a new product, is the delivery of this product from source to the customer fast enough? When we deploy a new service to a client, is the quality of that delivery as good as it could be? When designing a new process to replace several regional processes into one global process, is this process as Lean, efficient, and as effective as it could be? Are there any features that do not sit right with the principles of Lean? Asking these questions puts lean into a “design principle” mindset, where every time you look to decide on something you run it past the Lean test – is this solution Lean enough?

Lean thinking can be applied to your processes, products, people, and procedures, and the business improvement techniques that sit behind each one can vary. Therefore, it is really important to learn more about Lean and the tools available to you so that you can plan accordingly. What may work for one team or department may not work for all, which is fine. Just ensure you do not waste any time trying to deploy approaches that simply won’t fit with the problems facing that team. Do all of this, then you can deploy them in your organization today.

7. Place quality in products, processes, procedures, policies, and people central

The final of our business improvement techniques is to ensure quality in the 5 Ps. To do this, empower your colleagues to first identify what good quality looks like. This will involve them speaking directly with customers and clients to understand what it is they want, so they can replicate this into the outputs of the work being done.

Next, have them find the right ways to ensure quality. This would be through quality checking, adding controls to the process which are quality assured, and upskilling in quality qualifications like Total Quality Management to give colleagues the tools and techniques required. The benefit of upskilling people in qualifications such as Total Quality Management is that they can share this knowledge with their colleagues, immediate team, and the wider organization. You are not just upskilling one person for one benefit, but you now have great knowledge about how to deploy quality successfully in your organization. Use this and share this.

Lastly, have your colleagues report back on quality performance. Are we achieving our quality targets, SLAs, or KPIs? How are we achieving this? Why are we potentially not achieving this? What are we going to do to change the trajectory of performance here? The big win here, by deploying these business improvement techniques, is to shift the mindset. This push enforces quality as a mindset, the identification of it, the deployment of it, and the control of it. All of this will ripple out across the business, impacting performance and customer experience equally, and positively.

Lets Recap

Conclusion

This set of business improvement techniques is largely non-invasive, can be deployed relatively quickly, and can have an important, wider impact on the business. Many of the approaches are primed to deliver a positive ripple effect across your organization, for the benefit of colleagues, stakeholders, and customers alike.

A closing point when it comes to deploying business improvement techniques in your organization. Make sure you plan accordingly. These techniques, as impactful and successful as they are, will be deployed alongside other initiatives and business improvement techniques. What works for one individual, one team, department or product may not work for another. You must plan appropriately for their delivery, taking into consideration the needs of the wider business, the needs of the customer, and the expectations of Leadership.

Once you have done all of this, you can successfully deploy your business improvement techniques quickly and diligently within your organization.