Table of Contents

I. Downtime Is a Silent Killer

Every time a machine stops unexpectedly, the clock starts ticking—and not in your favor.

Unplanned downtime doesn’t just delay one order. It throws off schedules, burns through budgets, and frustrates teams. It’s like a slow leak in a tire—easy to ignore until you’re stranded.

Real example: A medium-sized plant runs 3 shifts a day. Just 30 minutes of unplanned downtime per shift = 7.5 hours lost per week. That’s nearly a full workday wasted—every week.

“If you don’t schedule maintenance, your equipment will schedule it for you.” – Unknown

Ignoring machine health is expensive. TPM is how you stay ahead of it.

II. What Is TPM? (Total Productive Maintenance)

TPM stands for Total Productive Maintenance. It’s a system where everyone takes care of the equipment—not just the maintenance team.

Operators do basic upkeep. Maintenance plans ahead. Managers support the process. TPM turns maintenance into a shared responsibility.

The goal is clear and simple:

- Zero breakdowns

- Zero defects

- Zero accidents

It started in Japan in the 1960s, built by Nippondenso, a key Toyota supplier. They proved that when people on the floor help take care of machines, those machines perform better—and last longer.

TPM isn’t a theory. It’s a factory-tested system that works.

III. Why TPM Matters

You don’t need a degree to understand this: if machines run better, the whole business runs better.

Here’s what TPM delivers:

- Longer machine life – Equipment stays healthier, longer.

- More uptime – No breakdowns means no production stoppages.

- Fewer defects – When machines are clean and tuned, quality improves.

- Safer working conditions – Well-maintained machines are less likely to cause accidents.

And the numbers back it up.

Companies that adopt TPM often boost their OEE (Overall Equipment Effectiveness) by 10–30%.

That’s not just efficiency. That’s margin, capacity, and customer satisfaction—up, up, up.

IV. The 8 Pillars of TPM (Broken Down Simply)

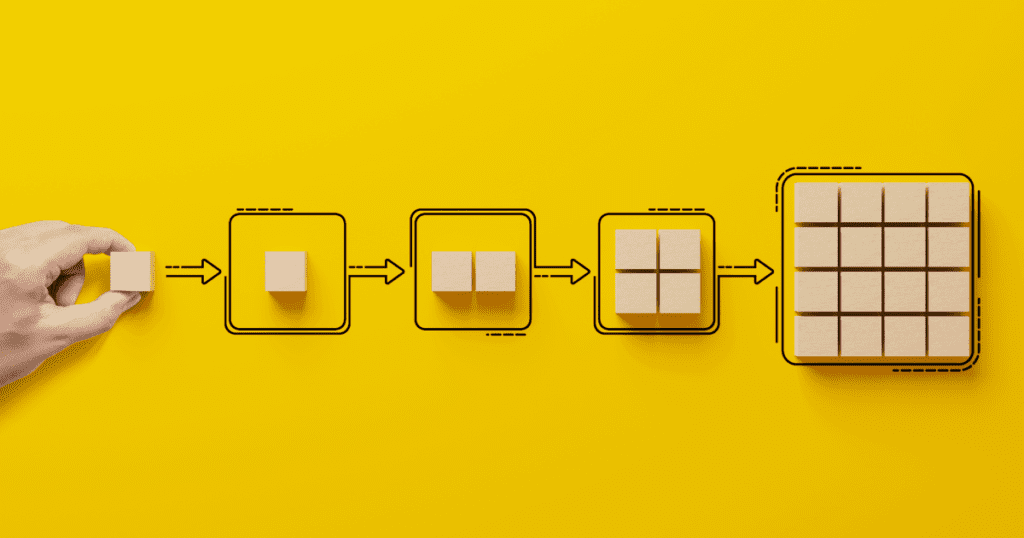

TPM isn’t one big thing. It’s eight simple habits, stacked together. Each one supports the others—and the result is fewer breakdowns, better output, and a stronger team.

1. Autonomous Maintenance

Operators don’t just run the machine—they help maintain it.

They clean, inspect, tighten bolts, and spot problems early.

Why it matters: Small problems get fixed before they become big ones.

2. Planned Maintenance

Stop fixing things after they break. Fix them before they do.

How: Schedule maintenance based on time, usage, or condition.

Why it matters: Planned downtime is way cheaper than surprise breakdowns.

3. Quality Maintenance

Find the real reason why defects happen—and remove it.

Example: A loose bolt causes slight misalignment, which ruins labels on every 10th product.

Why it matters: You fix the problem once instead of fixing the product every time.

4. Focused Improvement (Kaizen)

Small teams tackle small problems that slow things down.

How: Use data to find losses, then run mini-projects to eliminate them.

Why it matters: One tweak might save thousands over time.

5. Early Equipment Management

Build smarter from the start. Design new machines with maintenance in mind.

Why it matters: It’s easier to prevent issues in design than fix them in production.

6. Training & Education

Teach workers how to spot early signs of failure—and what to do about it.

Why it matters: Knowledge builds confidence. Confidence reduces mistakes.

7. Safety, Health & Environment

Make maintenance safe. No shortcuts. No injuries.

Why it matters: Healthy teams = reliable production.

8. TPM in Office Functions

Apply the same mindset to planning, purchasing, and scheduling.

Why it matters: A late order or wrong part can break a line just like a bad bearing.

V. Real-World Wins: TPM in Action

Case 1: Bottling Plant Boosts Uptime

A mid-sized beverage company used autonomous maintenance on its bottling lines. Workers started inspecting machines daily—cleaning, tightening, and reporting.

Result: Machine failures dropped by 40% in 6 months. Downtime nearly vanished.

Case 2: Automotive Factory Lifts Efficiency

An automotive parts maker ran TPM across its full plant. They trained staff, cleaned up machines, ran root cause analysis, and introduced planned maintenance.

Result: OEE jumped from 62% to 85%. More cars, fewer delays, and no added machines.

VI. TPM vs Traditional Maintenance

Let’s break it down. TPM isn’t just a different set of tools—it’s a different mindset.

| Traditional | TPM |

|---|---|

| Only maintenance team touches machines | Everyone is responsible |

| Fix it when it breaks | Prevent it from breaking |

| Reactive | Proactive |

Bottom line: Traditional waits for problems. TPM stops them before they start.

VII. Common TPM Mistakes

Even a solid system like TPM can flop if it’s done wrong. Watch out for these:

- Treating it like a project – TPM is not a one-time fix. It’s a daily habit.

- No buy-in – If the leadership shrugs, so will the floor team.

- Skipping training – People can’t own what they don’t understand.

- Focusing on tools, not culture – TPM only works if the mindset changes too.

Tip: Keep it simple. Start small. Build momentum.

VIII. TPM Tools That Make a Difference

You don’t need robots or AI to run TPM. Start with basic tools that actually work:

- Visual checklists – Operators know what to inspect, and when.

- Daily 5-minute inspections – Catch small issues before they grow.

- Root Cause Analysis – Use 5 Whys or Fishbone diagrams to dig deep.

- OEE dashboards – Track equipment health and spot trends fast.

Low cost. High impact.

IX. Wrap-Up: TPM = Fewer Breakdowns, More Profits

TPM isn’t about fixing machines—it’s about protecting uptime, quality, and safety.

And it’s not just for big factories. Any business with equipment, repeatable processes, or production lines can use it. TPM works best when everyone owns it—from the line operator to the CEO.

Final stat: Companies that apply TPM well often cut downtime by 20–50% within the first year.

That’s more output. Less waste. Higher profit.

TPM turns chaos into control—one machine at a time.

Total Quality Management | Certification Course

Buy Now for $9.99

Udemy prices may vary depending on applied coupons and promotional events.

- 🧑🏫 57 lectures

- ⌚ 5h 5m total length

- 🗃️ 8 downloadable resources

- 📜 Certificate of completion

- 👩🎓 9,427 students

- ⭐ 4.6 rating by 376 students