Table of Contents

I. Takt Time and Heijunka: Stop the Rush, Fix the Flow

When production doesn’t flow, everything feels like a fire drill.

Some days you’re buried in orders. Workers are stressed, machines are maxed out, and quality slips. Other days? Machines sit quiet, workers wait, and money bleeds out.

No rhythm. No balance. Just chaos.

“Flow is the key to productivity.” – Taiichi Ohno

Two tools fix this: Takt Time and Heijunka. One sets the pace. The other keeps it steady. Together, they turn the madness into momentum.

II. What Is Takt Time? (The Rhythm of Production)

Takt Time is your production beat.

It tells you how fast you need to make each unit to meet customer demand without rushing or stalling.

📐 The formula:

Takt Time = Available Production Time / Customer Demand

🔍 Example:

You have 8 working hours (28,800 seconds) and need to deliver 240 units.

Takt Time = 28,800 ÷ 240 = 120 seconds per unit.

That means you should finish one unit every 2 minutes to stay on track.

Think of it like a metronome in music. Too fast? You burn out. Too slow? You fall behind.

Takt Time keeps your production balanced, predictable, and focused on real demand.

III. What Is Heijunka? (Leveling the Load)

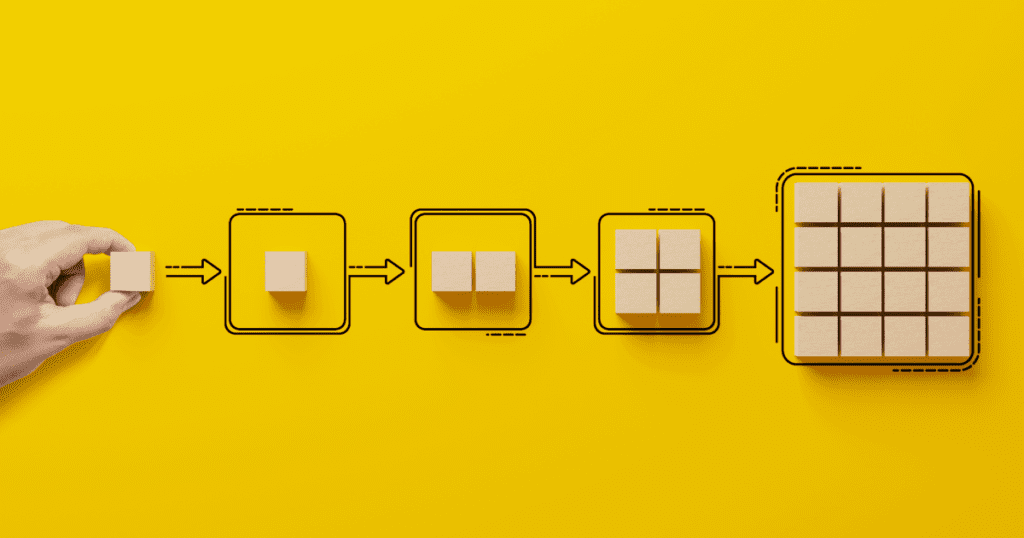

Even with perfect timing, uneven workloads will wreck your flow. That’s where Heijunka comes in.

Heijunka means leveling the load—making production steady, not spiky.

🎯 The goal:

- Make the same volume of product.

- At a steady pace.

- In small, consistent batches.

It was invented at Toyota to stop the old habit of “batch and push”—building tons of one product, then shifting to another. That method creates huge delays, stockpiles, and stress.

🍔 Real-world analogy:

Instead of cooking 50 burgers all at once and letting them get cold, cook one burger every 2 minutes as orders come in. Fresh, smooth, consistent.

Heijunka takes your takt rhythm—and makes sure it plays out evenly.

IV. Why These Two Work Best Together

Takt Time and Heijunka are like rhythm and melody—one sets the pace, the other makes it flow.

- Takt Time tells you how fast to produce.

- Heijunka makes sure you stay consistent at that pace.

When you only use Takt Time, production can still spike or stall due to messy order flows. When you only use Heijunka, you’re guessing the pace. But together?

🔧 They fix the four big flow killers:

- Overproduction – You only make what’s needed, when it’s needed.

- Waiting time – No long delays between orders or tasks.

- Inventory pileups – No extra stock collecting dust.

- Worker stress – No chaos, no burnout—just steady, smooth work.

Result: Better output. Happier teams. Leaner operations.

V. Examples of Takt Time & Heijunka in Action

🔌 Example 1: Electronics Factory

Goal: Make 60 units per hour.

- They set Takt Time = 60 seconds/unit.

- But orders used to pile up in the afternoon.

- So they used Heijunka to level demand across shifts.

Result: No last-minute chaos. Just clean, even production all day.

🍞 Example 2: Artisan Bakery

Old method: Bake 500 loaves at 6 AM. Freshness dropped. Waste climbed.

New system:

- Bake 50 loaves per hour based on Takt Time.

- Schedule small batches with Heijunka.

Result: Fresher bread, less overbaking, and better customer satisfaction.

VI. Visual Tools That Help

You don’t need fancy tech to run Takt Time and Heijunka. You just need tools that show the flow:

🧩 Heijunka Box

- A visual schedule board.

- Shows what to make and when—spread evenly through the day.

- Helps with mixed orders and small batch planning.

⏱️ Takt Boards

- Display real-time output vs takt goal.

- Workers and supervisors see if they’re ahead or falling behind.

🎨 Color-Coded Cards

- Great for mixed-model scheduling.

- Example: Red = Product A, Blue = Product B.

- Tells teams what to make next—without confusion.

These tools don’t just show information—they drive action.

VII. Common Pitfalls (And How to Avoid Them)

Even simple systems like Takt Time and Heijunka can go sideways if you don’t set them up right. Here’s what trips most teams up—and how to dodge it:

🚫 Miscalculating Takt Time

Takt Time only works if it’s based on real available time.

Mistake: Forgetting to subtract breaks, meetings, or planned downtime.

Fix: Only count actual work minutes. Precision matters.

🚫 Ignoring Demand Variability

You can’t level what’s unpredictable.

Mistake: Trying to force Heijunka on wildly fluctuating demand.

Fix: Use flexible planning and focus on the repeatable, high-volume items first.

🚫 Focusing on Speed, Not Stability

Takt isn’t about going faster—it’s about going steady.

Mistake: Teams rush to meet the time, causing defects and stress.

Fix: Prioritize flow and consistency, not just raw output.

✅ The Real Fix

Start small. Test one area. Adjust as you go.

Don’t aim for perfection—aim for smooth, repeatable rhythm.

VIII. Wrap-Up: Build Rhythm, Not Randomness

Takt Time and Heijunka aren’t just lean buzzwords. They’re your answer to daily chaos.

- Takt Time tells you how fast to work.

- Heijunka tells you how to plan that work.

Used together, they turn firefighting into flow—from the factory floor to the front office.

Final stat: Companies that apply Takt Time + Heijunka well often cut lead times by 30–60%, and improve on-time delivery by 20–40%.

No more overload. No more downtime. Just consistent, predictable progress.

Lean Management | Certification Course

Buy Now for $9.99

Udemy prices may vary depending on applied coupons and promotional events.

- 🧑🏫 61 lectures

- ⌚ 3h 51m total length

- 🗃️ 13 downloadable resource

- 📜 Certificate of completion

- 👩🎓 12,657 students

- ⭐ 4.7 rating by 511 students