Process improvement tools

Improving your processes is a highly recommended, extremely important and vitally critical activity. The activity is one which can lead to substantial benefits across your organization, with small to large-scale process improvements seeing a positive ripple effect across teams, operations, products and services.

To deliver process improvements, there are also a range of tools and techniques one can deploy. These tools are varied, deployed for many different reasons, in many different ways for a range of desired outcomes. In this article, we are going to explore 10 different tools available to you to secure the improvements you want, done so in a way which lasts the test of time.

Tool 1: Current state process mapping

When it comes to improving your processes, this is something that cannot be simply achieved in a vacuum. First, you need to understand what it is that is happening within your process, graphically. A process map enables you to secure this. Whether you take the flowchart, swim lane map, or workflow approach, all will give you great outcomes. They enable you to optimize the process by highlighting where you are seeing the majority of your issues, where waste is starting to build and from where common problems which are plaguing your performance arise.

Tool 2: Future state process mapping

Mapping out the process you want to see is also hugely powerful. This gives you something to aspire to. If you have your current state process map and future state one, you can use these two to identify the steps and activities you need to go through in order to achieve your desired outcomes. This gives you the insight to make some informed decisions about the change you need to make and enables you to build out a roadmap to deliver the change required. Your processes can be optimized much quicker by knowing clearly where you are today and where you want to be tomorrow.

Tool 3: Process improvement project work

This is one which can encompass all of the tools, but it is worth mentioning here. You can launch process improvement-specific projects, projects which are targeted at specific parts of the process with the aim of improving those parts. These improvements can revolve around reduction of waste, fixing something which is going wrong, or deploying a new system, solution or automation. Whatever it is, these projects are launched in the name of process improvement. Often, they will be delivered by experts in the fields of Lean Six Sigma, Continuous Improvement or change.

Tool 4: Kaizen event

Kaizen is the Japanese word for continuous improvement and can be deployed to optimize business performance in several ways. One common way is to hold Kaizen events. These are dedicated workshops or several days of workshops which are focused completely on improving a process, an operation or a problem. You gather together a team of people into a room (the team being those who work within the business or process regularly and know it inside and out), identify what the focus of the workshop is (improve X process, increase the operational efficiency of X department by X%) and use a range of tools to identify the changes you can make and outputs of those changes.

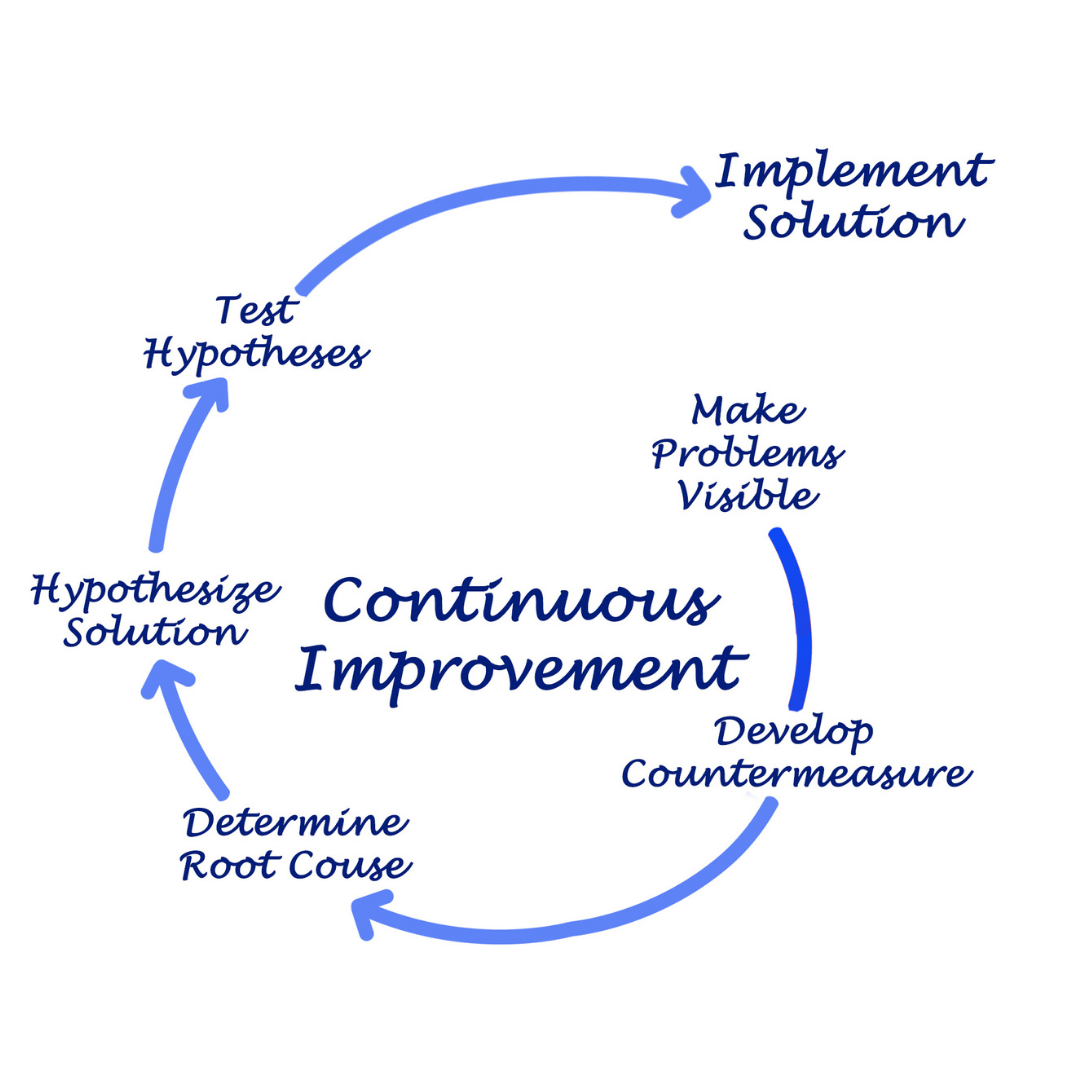

Tool 5: Kaizen rollout

Separate from Kaizen events (but possibly including them if required) is rolling out Kaizen more generally across the organization. This can include rolling out a program of continuous improvement across the business. This would see a dedicated team being established, individuals being trained up in continuous improvement methodologies and specific projects being launched. This would lead to a cultural shift which would be focused on improving the efficiency, effectiveness and productivity of processes in the business. Those who work within the Kaizen world of the business would be set targets regarding optimizing business performance.

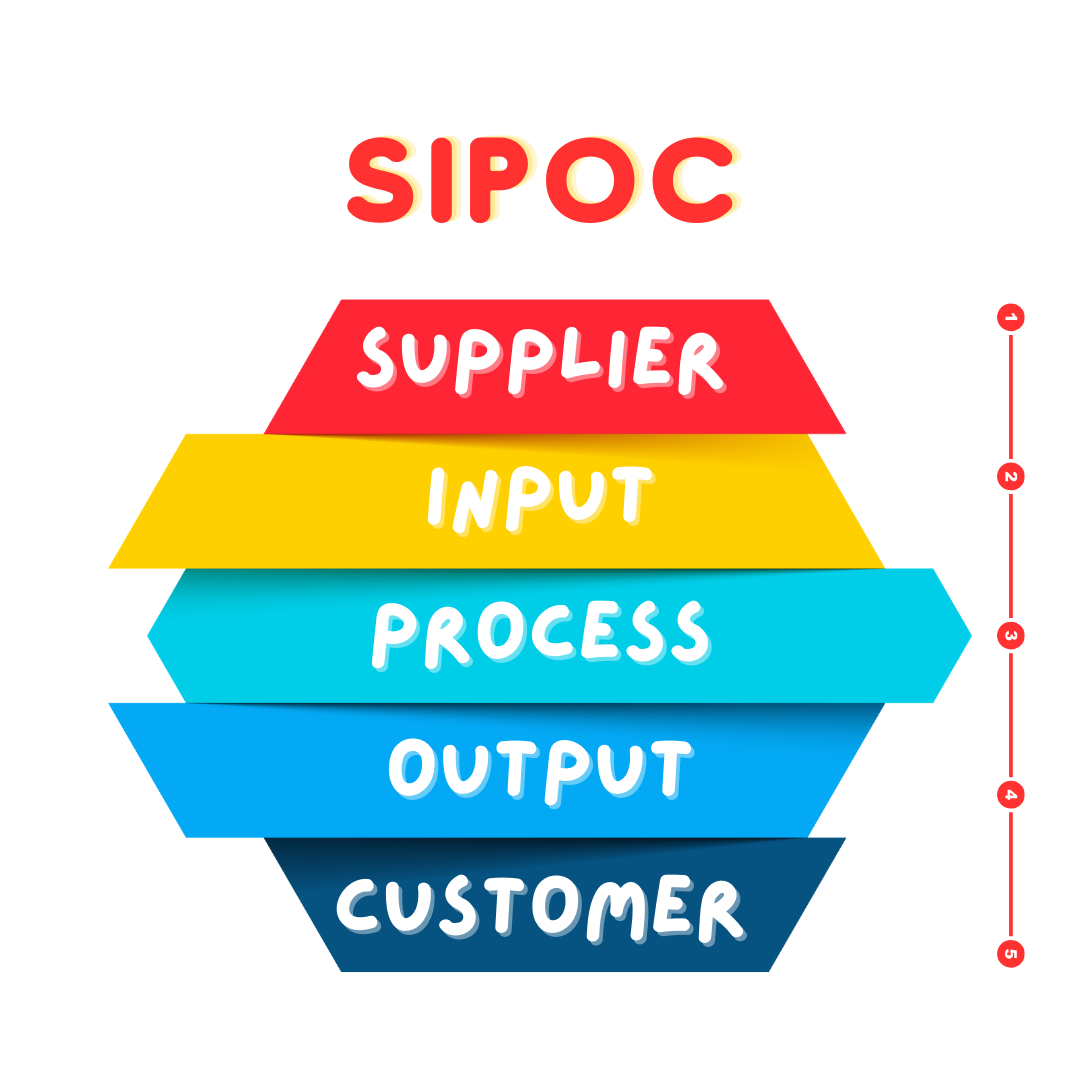

Tool 6: SIPOC diagram

Linked to process mapping but existing very much in its own world is the SIPOC diagram. SIPOC stands for supplier, input, process, output, customer and is a tool very much used to understand what data, information and raw materials are going into a process. It is also a great tool to see what is coming out of your process, and who is in receipt of this. You can optimize your business performance using this tool because you can understand clearly the journey of something through your process. You can understand better where this may be getting stuck or hitting roadblocks.

It is also a great way for you to understand the people involved in the process, end to end. All of this insight enables you to make better, more informed decisions on business improvement.

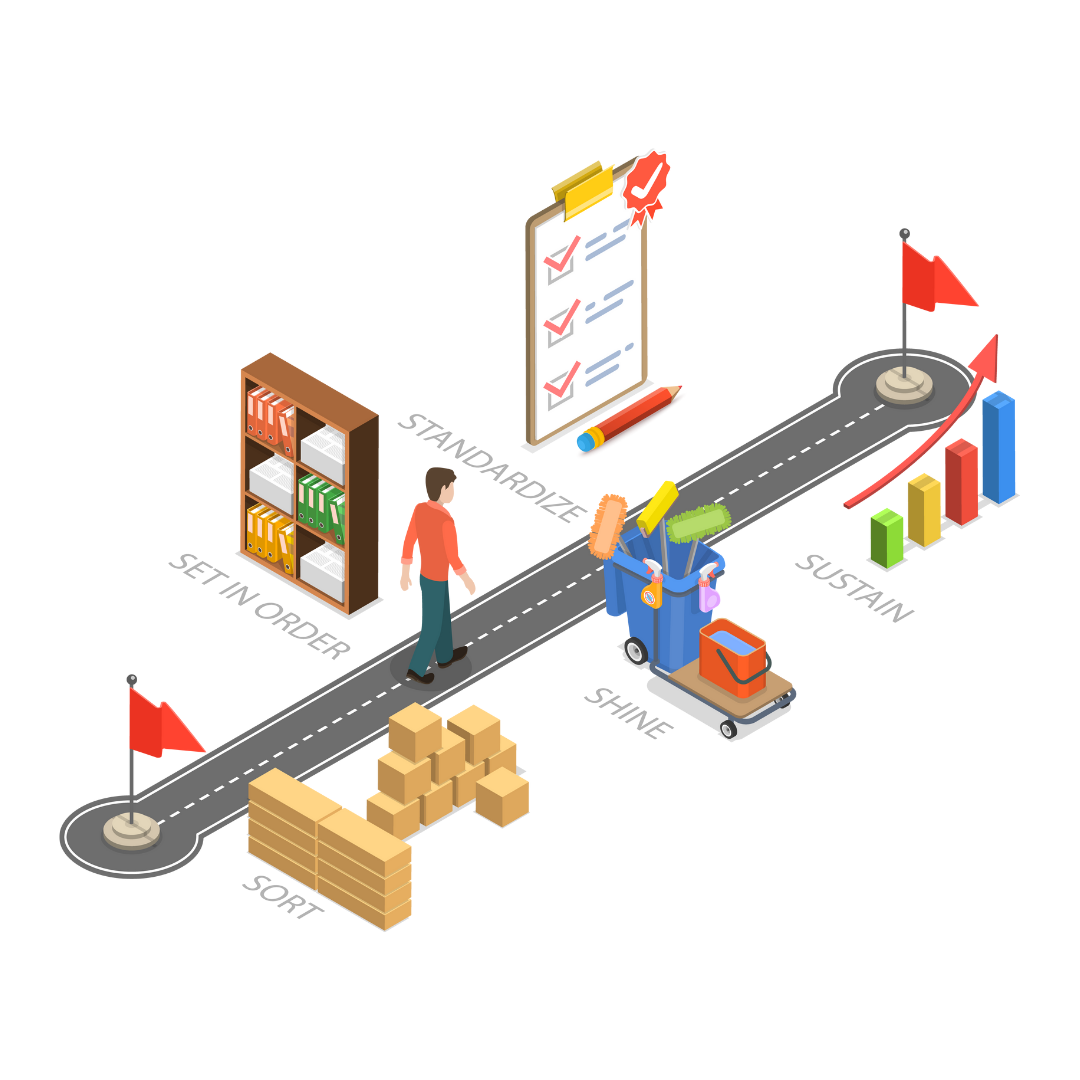

Tool 7: Lean Management

Deploying the tools of Lean is highly impactful. Lean is an approach to business improvement which focuses completely on identifying waste, locating it and removing it. It focuses on how to increase the value of your processes (optimizing them) by reducing the non-value-adding activities seen within the process. It hosts a range of tools that you can use to understand current performance, to identify what is potentially not working as expected and to diagnose why.

By using Lean techniques, you can find ways to reduce the cost of doing business, the time taken to complete that business and how to improve the products and services coming from your processes. It is focused on making your operations leaner, more efficient and more productive.

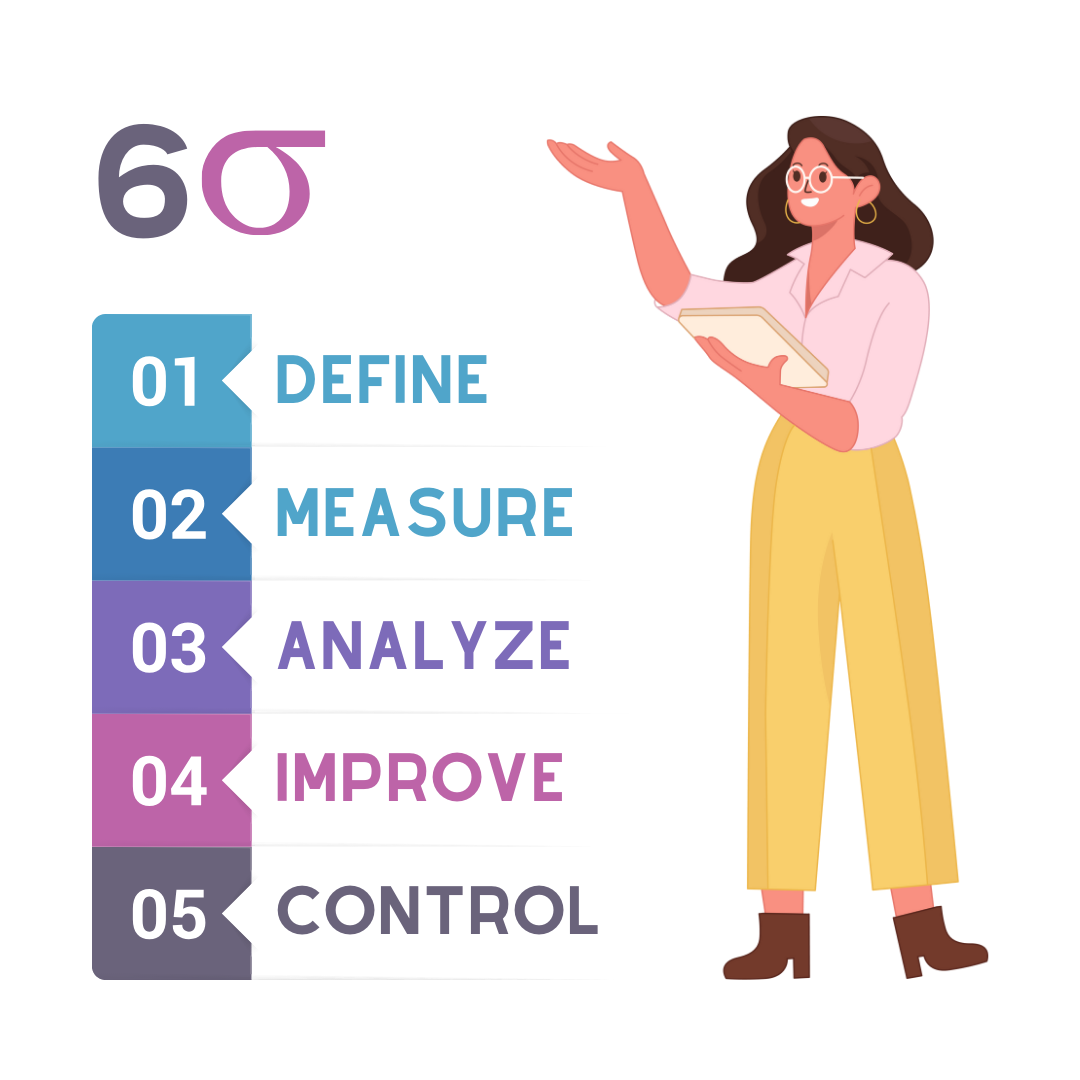

Tool 8: Six Sigma

Six Sigma is focused on improving the stability and capability of your process. You can optimize your operations and performance by understanding what is currently happening in your process which is causing it to be deemed as unstable (delivering what is expected but in an inconsistent way). Unstable processes can lead to errors which need to be handled internally and customer complaints which can lead to brand damage.

Equally, processes which are deemed not capable produce outputs which are not fit for purpose, have quality issues or are not as expected. This can also lead to unhappy customers. Six Sigma is focused on giving you the insight and the tools needed to optimize your processes so they remain stable and capable over the long term.

Tool 9: Root cause analysis tools

If you need to run through a range of potential causes, categorize them and land on the one or two causes which are the actual causes, you want to use the Fishbone Diagram. It is a great way for you to diagnose a problem and all of the ways in which it could be going wrong, ultimately landing on the actual cause and fixing this. With the 5 Whys Diagram, you can really focus in on those one or two actual causes and dive deeper and deeper until you find the absolute, final cause of your problem. From this, you can make better decisions around how to tackle the final cause to ensure it does not occur again.

Tool 10: Controls

A great way to not only optimize your processes and business performance but also to ensure any changes made last the test of time is by deploying controls. These controls can be built into your processes to ensure things either cannot go wrong or, when something does go wrong, something happens which triggers off an alert so it can be fixed quickly or an automatic fix comes into place.

For example, dashboards and KPIs are good ways for you to see how something is performing, tracking information in a process live. Equally, if you have a process, give it an owner. This person is then personally responsible for ensuring the process performs as expected, all documentation around it is up to date and if something does go wrong, it is addressed immediately.

Conclusion

When it comes to optimizing your processes, there are many ways to do this. They have been detailed in this article, but many more exist and exist within the tools mentioned above (i.e. root cause analysis, Lean, Six Sigma etc.) There are a range of methodologies such as Total Quality Management and Theory of Constraints which can also be deployed to improve operational performance.

The key to the successful delivery of this approach is to be clear. Clear on what it is you are seeking to achieve, the way you want to achieve it and the why. Once all of that is clear, building out your approach using the right process improvement tool will come naturally.