Table of Contents

Why Process Improvement is the Key to Business Success

Picture this: inefficiencies in business processes cost companies a staggering $1 trillion annually due to delays, redundancies, and errors. In today’s hyper-competitive market, organizations can’t afford to waste time or resources. This is where process improvement comes in—a systematic approach to transforming inefficiencies into opportunities for growth.

Process improvement isn’t just about shaving off a few minutes here or saving a few dollars there. It’s about creating a culture of continuous improvement that empowers your team, delights your customers, and drives your bottom line.

What You’ll Learn

In this guide, you’ll uncover:

- What process improvement is and why it matters.

- Proven methodologies like Lean, Six Sigma, and Kaizen.

- Step-by-step strategies to optimize workflows.

- Tools and technologies to take your processes to the next level.

- Real-world examples of businesses that have achieved incredible results.

By the end, you’ll have everything you need to transform your processes, reduce waste, and build a more agile, productive, and efficient organization. Let’s dive in.

What is Process Improvement?

The Definition

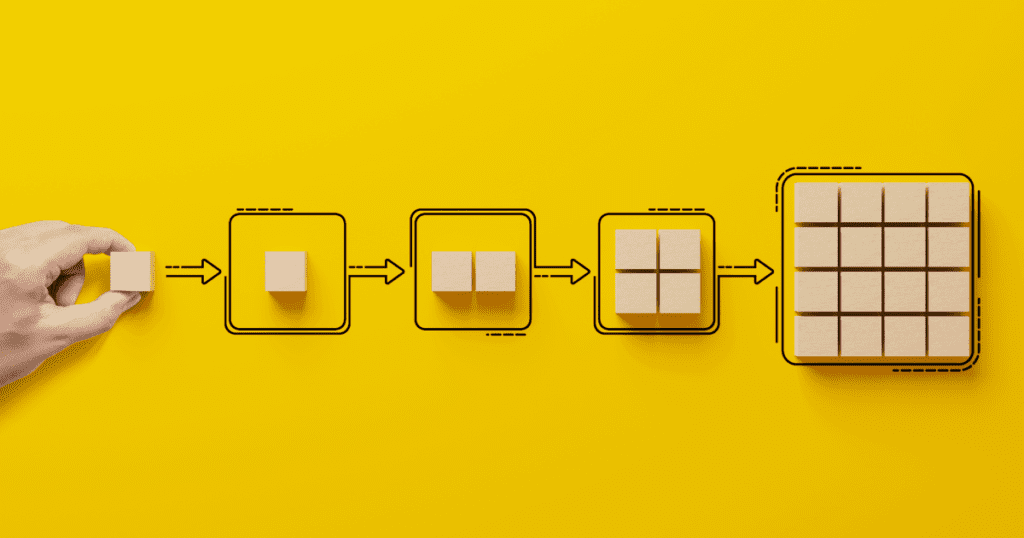

At its core, process improvement is about identifying, analyzing, and enhancing business workflows to achieve better results. This means reducing waste, eliminating inefficiencies, and optimizing every step of a process to align with your organization’s goals.

It’s often referred to as business process improvement (BPI) and involves structured efforts to make processes faster, more reliable, and less resource-intensive.

Breaking It Down: What Does It Really Mean?

Let’s make it simpler. Imagine a bakery that produces 1,000 loaves of bread daily. If their mixing process takes 30 minutes longer than it should, it limits the number of loaves they can bake. By streamlining the mixing process—say, by investing in a more efficient mixer or reorganizing the workflow—they can save time, reduce waste, and produce more bread, increasing both profits and customer satisfaction.

This is process improvement in action—making small changes that drive big results.

How Does It Work?

Process improvement works by:

- Identifying inefficiencies: Spotting delays, redundancies, or bottlenecks in your workflow.

- Analyzing root causes: Using tools like the “5 Whys” or root cause analysis to uncover what’s really going wrong.

- Implementing solutions: Simplifying, automating, or redesigning processes to make them more efficient.

A Part of a Bigger Picture

Process improvement is a key component of larger business frameworks like:

- Business Process Management (BPM): The discipline of managing and optimizing all organizational processes.

- Continuous Process Improvement (CPI): A mindset of always seeking better ways to work, driven by small, incremental changes.

It’s also distinct from process optimization, which focuses on maximizing the performance of already streamlined processes. Think of process improvement as fixing a rusty car engine, and process optimization as tuning it to peak performance.

The Universality of Process Improvement

The beauty of process improvement is its universal applicability. Whether you’re in manufacturing, healthcare, finance, or even education, every organization has processes that can be made better. For example:

- A hospital might improve patient intake by automating form submissions.

- A retail store might reduce inventory errors by implementing a barcode scanning system.

- A tech company might cut project delays by refining team collaboration workflows.

Why It’s Not a One-Time Fix

Processes evolve as your business grows, technologies change, and customer expectations shift. This means process improvement is not a one-and-done effort—it’s an ongoing journey.

In the next section, we’ll explore why process improvement is not just nice to have—it’s absolutely critical to your organization’s success.

Why Process Improvement Matters

Every day, organizations lose vast amounts of time, money, and effort due to inefficiencies in their processes. Research shows that inefficiencies cost businesses 20–30% of their revenue annually. Imagine employees spending 36% of their workweek searching for information or clarifying tasks, as found by an IDC report. Or consider how bottlenecks in workflows can delay product launches, disrupt customer service, and create mounting frustration for your team.

“Research by McKinsey shows that businesses that focus on improving processes see up to 30% higher productivity gains than those that don’t.”

The ripple effects of inefficient processes are far-reaching. When tasks take longer than expected, deadlines are missed, costs soar, and customer satisfaction plummets. For instance, a financial services firm recently found that manual invoicing processes led to repeated late payments, racking up thousands in penalty fees. After automating the invoicing system, the company not only eliminated the penalties but also reclaimed valuable staff hours for strategic tasks.

Key Benefits of Process Improvement

1. Time Savings and Cost Reductions

Streamlined workflows eliminate redundant steps, reducing both time and operational costs. Consider a retailer that automated its inventory management process: what once required five hours of manual checks per month now takes just thirty minutes, saving hundreds of staff hours annually

2. Better Customer Experiences

Customers today expect swift, reliable service. A healthcare clinic that optimized its patient intake process by introducing digital forms reduced the time spent on onboarding by 66%. This not only delighted patients but also improved the clinic’s operational flow

3. Boosting Employee Morale

Frustrated employees who wrestle with outdated systems often feel unproductive and burnt out. By simplifying processes, companies empower teams to focus on meaningful work. According to Deloitte, organizations that prioritize workflow optimization report a 22% decrease in employee turnover, showing how process improvement positively impacts workplace culture.

5. Scalability and Agility

Scalability and adaptability are among the most critical advantages of process improvement. Efficient processes make it easier to expand operations without sacrificing quality. For example, an e-commerce company that optimized its order fulfillment system was able to seamlessly handle a 40% surge in holiday orders, avoiding delays and exceeding customer expectations. Similarly, agile workflows help organizations respond swiftly to changing market conditions or customer needs, providing a competitive edge.

Modern Business Necessity

In a rapidly evolving world, process improvement is no longer optional. Organizations face constant pressure to innovate, reduce costs, and deliver more value to their customers. Businesses that embrace continuous improvement enjoy 20% higher operational efficiency within two years, according to Forbes. Without a commitment to refining processes, even the most established companies risk falling behind.

Whether you’re a startup or a multinational corporation, process improvement is the foundation of long-term resilience and success.

Types of Process Improvement

Process improvement isn’t a one-size-fits-all endeavor. Depending on the problem at hand, businesses may need to choose between making small adjustments or overhauling entire systems. Understanding the different approaches can help you craft the right solution for your organization’s unique challenges.

Incremental Improvement

This approach focuses on gradual, ongoing adjustments to existing workflows, inspired by the Kaizen philosophy of continuous improvement. By addressing minor inefficiencies regularly, companies can achieve significant long-term gains without disrupting operations.

For example, a customer support team at a software company reduced ticket resolution times by reorganizing how tickets were prioritized. This small change, implemented over a few weeks, had a compounding effect: customers received faster service, while employees found it easier to manage workloads.

Transformational Improvement

When processes are fundamentally flawed or outdated, transformational improvement—also known as Business Process Reengineering (BPR)—is the answer. This involves completely redesigning a workflow to achieve dramatic improvements in efficiency, cost, or quality.

A manufacturing firm struggling with long production cycles revamped its assembly line by investing in automation and redistributing labor. As a result, lead times were cut in half, enabling the company to take on more orders and scale its operations.

Ongoing Process Optimization

Sometimes, even improved processes can perform better. Optimization focuses on pushing workflows to their peak efficiency, often using advanced technologies like predictive analytics or machine learning.

For instance, a logistics company utilized AI to analyze delivery routes in real-time, identifying the fastest paths for drivers. This optimization reduced fuel costs and delivery times, giving the company a competitive edge.

Reactive vs. Proactive Improvement

Some changes happen reactively, in response to specific problems like customer complaints or missed deadlines. For example, a retail store experiencing long checkout lines added self-checkout kiosks to address customer frustration.

Proactive improvement, on the other hand, anticipates issues before they arise. A restaurant preparing for rapid growth restructured its kitchen layout to handle higher order volumes, ensuring continued efficiency as demand increased.

Real-World Application: Choosing the Right Approach

Choosing the right approach depends on your goals and circumstances:

- Incremental improvement is ideal for minor inefficiencies that don’t require a full-scale overhaul.

- Transformational improvement suits processes that are outdated or misaligned with organizational objectives.

- Ongoing optimization focuses on perfecting already efficient workflows to stay competitive.

For instance, a regional hospital initially adopted transformational improvement by automating its appointment scheduling system to address patient complaints. Later, it implemented incremental improvements by adding features like automated reminders and self-check-in kiosks to further enhance the patient experience.

The Versatility of Process Improvement

What makes process improvement so powerful is its flexibility. Organizations can mix and match approaches based on their needs. For example, a retailer might start with reactive fixes like reducing waiting times at checkout, then move on to proactive optimization, such as implementing AI-powered customer tracking for personalized offers.

This versatility ensures that process improvement can adapt to businesses of all sizes, industries, and stages of growth.

Triggers of Process Improvement – How to Spot When It’s Needed

No organization runs perfectly all the time. Processes can degrade over time due to scaling, changing technologies, market shifts, or inefficiencies that creep in unnoticed. But how do you know when it’s time to step in and improve? Identifying the triggers of process improvement is crucial for maintaining operational excellence.

1. Increased Time and Delays

One of the clearest signals that a process needs attention is when it starts taking longer than usual to deliver results. For example, a procurement process that once completed purchase orders in two days now takes a week, causing delays across departments.

These delays often indicate the introduction of unnecessary steps, outdated systems, or an imbalance in resource allocation. Addressing such inefficiencies can help regain speed and reduce downstream disruptions.

2. Repeated Errors or Quality Issues

Frequent mistakes in a process are a red flag. If errors are recurring—whether in data entry, billing, or production—it’s a sign the system is prone to human error or lacks proper checks.

For instance, a finance department finding duplicate invoices during every month-end reconciliation isn’t just experiencing an annoyance; it’s losing valuable time and risking financial inaccuracies. Root cause analysis can uncover if the issue stems from poor communication, inadequate tools, or unclear procedures.

3. Decline in Customer Satisfaction

If customers start voicing dissatisfaction—through complaints, lower ratings, or churn—it’s time to examine your processes.

For example, a logistics company receiving repeated feedback about delayed shipments might uncover inefficiencies in its fulfilment process, such as poor inventory management or delayed handoffs between teams. Improving the fulfilment workflow can directly enhance customer experiences and loyalty.

4. Escalating Costs Without Proportional Returns

A consistent rise in operational costs without corresponding improvements in output or revenue is another clear indicator. This can occur when processes are overcomplicated, require excessive manpower, or involve redundant tasks.

Take a production plant where overtime pay has doubled in recent months, yet output remains unchanged. A deep dive into workflows might reveal unnecessary steps or poor resource utilization, pointing the way to cost-cutting process improvements.

5. Growing Bottlenecks

When bottlenecks become routine, it’s a sign that processes are no longer scaling with the demands of the business.

For example, a growing e-commerce business may find its manual order processing overwhelmed by increased holiday sales, causing delays and errors. Implementing automation can eliminate bottlenecks, allowing for smooth scaling.

6. Low Employee Engagement or Morale

When employees express frustration or disengagement, it’s often linked to inefficient processes. Tasks that are overly manual, repetitive, or unclear can demoralize teams and lead to burnout.

For instance, a customer service team spending hours daily on manual data entry is likely to feel undervalued. Streamlining these tasks with automation not only boosts morale but frees employees for more meaningful work.

7. Missed Deadlines and SLAs

Consistently failing to meet deadlines or service-level agreements (SLAs) can erode trust with clients, partners, or internal stakeholders.

For example, a marketing agency that repeatedly misses content delivery deadlines might discover inefficiencies in its project management processes, such as unclear task delegation or a lack of resource prioritization. Process improvement can realign workflows to ensure timely delivery.

8. Market Changes and Competitive Pressure

Evolving customer expectations or new market dynamics often necessitate process improvements.

A retail chain competing with same-day delivery services might need to overhaul its distribution process to stay competitive. Ignoring such triggers risks falling behind in the market.

9. Technology Advancements or Limitations

The introduction of new technology—or the limitations of outdated systems—can both be triggers for process improvement.

For example, a company still relying on legacy software for HR processes might face inefficiencies in payroll or recruitment. Upgrading to modern, cloud-based systems can streamline these processes and improve overall performance.

10. Audit Findings and Compliance Gaps

Regulatory audits often uncover inefficiencies or compliance risks in processes. Addressing these not only ensures legal adherence but also streamlines operations.

For instance, a pharmaceutical company fined for incomplete supply chain documentation can use process improvement to implement better tracking and reporting systems, avoiding future penalties.

Real-World Example: Identifying the Trigger

Consider a national insurance provider struggling with a backlog in claims processing. Customers complained about delays, employees felt overwhelmed, and operational costs were rising due to overtime hours. A root cause analysis revealed that their claims process relied heavily on manual data entry, creating errors and bottlenecks. By automating data extraction and implementing digital workflows, the company reduced claims processing times by 40%, increased customer satisfaction, and cut overtime costs by 25%.

How to Respond to Triggers Effectively

- Start with Analysis: Use tools like value stream mapping or the “5 Whys” to pinpoint the root causes of inefficiencies.

- Engage Stakeholders: Involve the people closest to the process—they often have valuable insights into what’s going wrong.

- Prioritize Actions: Tackle the highest-impact areas first to gain quick wins and build momentum.

- Monitor and Iterate: After implementing changes, measure their success and refine further as needed.

Proactive vs. Reactive Responses

Some organizations wait for triggers like errors or delays to take action—this is a reactive approach. Others adopt a proactive stance, regularly evaluating processes to anticipate potential inefficiencies before they cause problems. Proactive organizations are better equipped to stay agile, competitive, and resilient.

Process improvement triggers aren’t nuisances—they’re opportunities. By recognizing these signs and acting decisively, you can transform inefficiencies into strengths. Whether it’s improving speed, reducing costs, or delighting customers, addressing these triggers ensures your organization is always moving forward.

The Process of Process Improvement

To achieve meaningful and lasting results, process improvement must follow a structured, step-by-step approach. Skipping steps or rushing implementation often leads to suboptimal outcomes or outright failure. This section outlines a proven framework that guides organizations from identifying inefficiencies to implementing and sustaining impactful improvements.

Step 1: Identify the Process in Need of Improvement

Before embarking on any improvement initiative, you must pinpoint the specific process that requires attention. This often involves:

- Spotting Triggers: Indicators such as delays, errors, or customer complaints serve as signs of inefficiencies.

- Defining the Process: Clearly outline the boundaries and scope of the process to avoid confusion later. For instance, improving a “billing workflow” might mean focusing solely on invoice generation rather than the entire financial process.

The key here is to define the problem with precision. Fuzzy or vague problem areas make improvement initiatives scattershot and harder to manage.

Step 2: Map the “As-Is” Process

To improve a process, you need to understand how it currently operates. Create a detailed visual representation of the workflow, including:

- Key steps and activities

- Involved stakeholders and systems

- Handoffs, bottlenecks, and delays

- Metrics such as time, cost, and error rates

Common tools for mapping include flowcharts, swimlane diagrams, and value stream mapping (VSM).

For example, mapping a product delivery workflow might reveal inefficiencies like unnecessary approvals or unclear roles that cause frequent delays.

Key Tip: Engage employees who actively participate in the process to ensure accuracy. Frontline workers often provide insights into pain points that management might overlook.

Step 3: Analyze the Current Process

Once the “as-is” map is ready, analyze the process to uncover inefficiencies, waste, and root causes of problems. Use tools such as:

- Root Cause Analysis (RCA): Dig deeper to identify the true source of inefficiencies.

- The 5 Whys: Repeatedly ask “why” to move beyond surface-level issues.

- Fishbone Diagrams: Visualize contributing factors to problems, such as delays or errors.

Collecting baseline performance data is crucial. For example, if errors occur at a specific stage, track their frequency, causes, and impact. This will serve as a benchmark when measuring the effectiveness of improvements later.

Step 4: Design the “To-Be” Process

Using insights from your analysis, design an optimized version of the process. This “future state” should eliminate inefficiencies, reduce complexity, and deliver better outcomes. To achieve this:

- Simplify: Remove unnecessary steps and consolidate repetitive activities.

- Automate: Identify opportunities for technology to streamline workflows.

- Reassign: Ensure tasks align with employees’ strengths and roles.

For instance, a repetitive manual task like data entry might be replaced with automated tools, allowing employees to focus on more strategic activities. The goal is to make the process leaner, faster, and more aligned with organizational objectives.

Step 5: Conduct a Gap Analysis

Compare the current (as-is) process to the future (to-be) state and identify what needs to change to bridge the gap. Consider:

- Resources required (e.g., new technology, training)

- Potential risks and barriers

- Organizational readiness for change

Output: A comprehensive action plan listing the steps, timeline, and stakeholders involved in implementing the changes. This ensures a clear path forward while addressing potential obstacles.

Step 6: Test the New Process

Before rolling out changes organization-wide, test the improved process on a smaller scale. This allows you to:

- Identify unforeseen challenges

- Validate assumptions

- Gather feedback from participants

For example, if you’ve redesigned a customer support workflow, pilot it with one team to ensure the changes improve response times without compromising service quality.

Step 7: Implement and Communicate

After successful testing, roll out the changes across the organization. Effective implementation depends on:

- Training: Equip employees with the knowledge and skills needed to adapt to the updated process.

- Clear Communication: Explain the benefits and expected outcomes to gain buy-in from all stakeholders.

- Monitoring Tools: Use dashboards or KPIs to track progress and ensure smooth adoption.

Step 8: Measure Results

Evaluate the performance of the new process against your baseline metrics. Key performance indicators (KPIs) might include:

- Time savings

- Reduction in error rates

- Cost savings

- Improved satisfaction levels (customers or employees)

For instance, a redesigned sales process might result in faster deal closures and a higher conversion rate, which can be tracked and quantified.

Step 9: Sustain and Optimize

Process improvement is not a one-time effort. To ensure long-term success:

- Document Standard Operating Procedures (SOPs): Clearly outline the steps of the improved process.

- Conduct Regular Reviews: Continuously assess the process to ensure it adapts to changing business needs.

- Foster a Culture of Improvement: Encourage employees to suggest further refinements or highlight emerging issues.

Organizations that consistently refine their processes are more resilient, adaptable, and competitive in the long term.

The process of process improvement is a cyclical journey. Each iteration builds on the previous one, driving efficiencies and delivering greater value to customers and stakeholders. By following these structured steps, organizations can address current inefficiencies and position themselves for sustained success.

Popular Process Improvement Methodologies (and How to Choose One)

When it comes to process improvement, selecting the right methodology is essential. Each approach offers unique frameworks, tools, and strengths tailored to different organizational needs. This section dives into the most popular methodologies, providing a comparison of their focus, strengths, weaknesses, and best use cases to help you make an informed choice.

We offer in-depth courses on these methodologies. Check out the lessons and sample videos to see the value for yourself. 👉 LBI Certification Courses

1. Total Quality Management (TQM)

Focus: Customer satisfaction through organization-wide continuous improvement.

Overview:

TQM integrates every department into the improvement process, emphasizing collaboration, data-driven decisions, and customer-centricity. Organizations using TQM align their processes with customer expectations, continuously monitoring and refining them to ensure long-term success.

Strengths:

- Encourages organization-wide involvement.

- Builds a culture of quality and customer focus.

- Highly adaptable across industries.

Weaknesses:

- Can be slow to implement due to its comprehensive scope.

- Requires sustained commitment from leadership and employees.

Best Use Cases:

TQM is ideal for companies focused on long-term customer loyalty and quality improvement, such as manufacturing, logistics, or customer service industries.

2. Lean

Focus: Waste elimination to maximize value delivery.

Overview:

Lean methodology, derived from Toyota’s manufacturing principles, identifies and removes non-value-adding activities (waste) in processes. Its key tools include value stream mapping, the 5 Whys, and Kanban boards.

Strengths:

- Rapid results through waste reduction.

- Improves workflow efficiency and employee productivity.

- Flexible and scalable across industries.

Weaknesses:

- May overlook long-term strategic improvements.

- Heavily reliant on accurate data and employee buy-in.

Best Use Cases:

Lean is a great fit for industries requiring streamlined production or service delivery, such as retail, healthcare, and manufacturing.

3. Six Sigma

Focus: Reducing defects and variability through statistical analysis.

Overview:

Six Sigma uses data-driven techniques to identify and minimize defects, aiming for near-perfection (3.4 defects per million opportunities). It employs two main frameworks:

- DMAIC (Define, Measure, Analyze, Improve, Control): Used for improving existing processes.

- DMADV (Define, Measure, Analyze, Design, Verify): Used for designing new processes.

Strengths:

- Highly structured and quantifiable.

- Excellent for improving quality in high-stakes industries.

- Promotes data-driven decision-making.

Weaknesses:

- Resource-intensive, requiring training and certification (e.g., Green Belts, Black Belts).

- May not address root causes effectively in highly dynamic environments.

Best Use Cases:

Six Sigma is well-suited for industries like manufacturing, aviation, and healthcare, where precision and quality are paramount.

4. Kaizen

Focus: Continuous, incremental improvements across all levels.

Overview:

Kaizen, meaning “change for better” in Japanese, promotes a mindset of ongoing improvement. It empowers employees to suggest and implement small changes, fostering collaboration and sustained progress. Kaizen operates through tools like the 5S framework (Sort, Set in Order, Shine, Standardize, Sustain) and PDSA (Plan, Do, Study, Act) cycles.

Strengths:

- Builds a strong culture of teamwork and innovation.

- Focuses on gradual, consistent improvements.

- Low cost and easy to implement.

Weaknesses:

- Incremental changes may not address systemic inefficiencies.

- Requires high engagement across all levels of the organization.

Best Use Cases:

Kaizen works best in environments with repetitive processes, such as assembly lines, customer service teams, and administrative functions.

5. Theory of Constraints (TOC)

Focus: Identifying and addressing the bottleneck that limits overall system performance.

Overview:

TOC assumes that every process has at least one constraint that limits its efficiency. By systematically identifying and addressing this bottleneck, organizations can improve throughput and performance. TOC follows a five-step process:

- Identify the constraint.

- Exploit the constraint.

- Subordinate other processes to the constraint.

- Elevate the constraint.

- Repeat the process for continuous improvement.

Strengths:

- Laser-focused on removing critical inefficiencies.

- Improves overall system performance rather than isolated tasks.

- Requires minimal initial investment.

Weaknesses:

- Limited applicability to processes without clear bottlenecks.

- May oversimplify complex systems.

Best Use Cases:

TOC excels in supply chain management, project management, and manufacturing, where bottlenecks often hinder progress.

Comparison Table: Choosing the Right Methodology

| Methodology | Focus | Strengths | Weaknesses | Best Use Cases |

|---|---|---|---|---|

| TQM | Customer-centric continuous improvement | Organization-wide involvement; customer satisfaction; long-term benefits | Slow to implement; high resource commitment | Manufacturing, logistics, customer service |

| Lean | Waste elimination | Rapid results; scalable; improves employee productivity | May overlook long-term improvements; data-intensive | Healthcare, retail, manufacturing |

| Six Sigma | Defect and variability reduction | Data-driven; structured; quality-focused | Resource-intensive; requires certification | Healthcare, aviation, manufacturing |

| Kaizen | Incremental, continuous improvement | Low cost; fosters teamwork; easy to implement | Incremental improvements may not address systemic problems | Repetitive processes, service industries |

| TOC | Bottleneck removal | Focused on critical inefficiencies; minimal investment required | Limited to bottlenecked systems; may oversimplify | Supply chain, project management |

How to Choose the Right Methodology

Selecting the right methodology depends on your organization’s unique needs, resources, and goals. Consider the following factors:

- Scope of the Issue: Use Kaizen or Lean for small, incremental changes; TQM or Six Sigma for broader, systemic issues.

- Resource Availability: Lean and TOC require minimal resources, while Six Sigma demands heavy investment in training and tools.

- Urgency: Lean and TOC deliver faster results; TQM and Six Sigma excel in long-term transformation.

- Industry and Culture: Some industries, like aviation, are more suited to Six Sigma, while others, like customer service, thrive on Kaizen.

By aligning your choice with your business goals, you can maximize the benefits of process improvement and drive sustained success.

Tools and Techniques for Process Improvement

In any process improvement initiative, having the right tools and techniques can mean the difference between success and frustration. These tools not only help streamline workflows but also enhance analysis, collaboration, and implementation. Below, we’ll explore the most effective tools and techniques for improving processes across industries.

Templates simplify learning and speed up work. Explore the free downloadable templates we’ve created for you. 👉 Template Collection

1. Process Mapping Tools

Process mapping is foundational to understanding workflows, identifying inefficiencies, and designing solutions. Visualizing processes helps teams align on problem areas and proposed changes.

Common Techniques:

- Flowcharts: Straightforward diagrams that map out each step in a process.

- Swimlane Diagrams: Highlight roles and responsibilities by visually separating tasks into lanes.

- Value Stream Mapping (VSM): Tracks the flow of materials and information in a process, pinpointing areas of waste.

How They Help:

Imagine a team struggling with project delays. A swimlane diagram could reveal unnecessary handoffs between departments, allowing the organization to consolidate tasks and reduce bottlenecks.

2. Cause-and-Effect Analysis

Also known as a fishbone or Ishikawa diagram, this tool helps identify root causes of problems. It categorizes contributing factors—such as people, technology, methods, or materials—making it easier to focus improvement efforts.

Use Case:

For a customer support team experiencing frequent complaint escalations, a fishbone diagram might reveal that unclear policies and insufficient training are causing inconsistency in responses.

3. The “5 Whys” Technique

5 Whys is a simple yet powerful tool to uncover the root cause of a problem by repeatedly asking “Why?” five times (or as many as needed).

Example:

Problem: Delayed project delivery.

- Why? Deliverables weren’t ready on time.

- Why? Team members waited on approvals.

- Why? Approvals were delayed.

- Why? Managers were unaware of deadlines.

- Why? No automated reminders in the system.

Solution: Implement an automated task notification system.

4. Kanban Boards

Kanban boards, whether physical or digital, organize tasks visually, making workflows more transparent. Tasks are categorized into stages, such as “To Do,” “In Progress,” and “Completed.”

Benefits:

- Simplifies workflow tracking

- Highlights bottlenecks in real time

- Encourages team collaboration

Popular Tools:

- Trello

- Jira

- Monday.com

5. SIPOC Diagrams

SIPOC stands for Suppliers, Inputs, Process, Outputs, and Customers. It provides a high-level overview of a process, helping teams understand key dependencies and stakeholders.

Use Case:

A company planning to optimize its procurement process could use a SIPOC diagram to identify gaps in communication between suppliers and procurement staff, ensuring smoother handoffs.

6. Business Process Automation Tools

Automation tools reduce manual effort, improve accuracy, and increase efficiency. By leveraging technologies like Robotic Process Automation (RPA) or no-code platforms, organizations can digitize repetitive tasks.

Common Solutions:

- Pipefy: No-code process automation with visual workflows.

- UiPath: RPA tool for automating tasks like data entry and invoice processing.

- Zapier: Integrates apps and automates workflows.

Example:

A finance department can use RPA to automatically reconcile accounts, reducing errors and freeing up employees for strategic activities.

7. Data Analysis and Visualization Tools

Data plays a critical role in evaluating process performance and identifying opportunities for improvement. Tools like dashboards and analytics software help teams track metrics and make data-driven decisions.

Popular Tools:

- Power BI: Offers advanced analytics and dashboards.

- Tableau: Simplifies data visualization for actionable insights.

Example:

By analyzing sales data, a team could pinpoint underperforming territories and adjust marketing strategies to improve conversion rates.

8. Collaboration and Communication Tools

Improving processes often involves cross-functional collaboration. Tools that enable seamless communication and file sharing can bridge gaps between teams.

Popular Platforms:

- Slack: Real-time messaging for quick collaboration.

- Microsoft Teams: Combines chat, video, and document sharing.

- Google Workspace: Simplifies shared document editing.

Example:

A product development team can use shared folders and instant messaging to streamline feedback loops and accelerate approvals.

9. Root Cause Analysis (RCA)

Root Cause Analysis digs deep into problems to identify their underlying causes rather than treating symptoms. Techniques like fault tree analysis and current reality trees support this approach.

Example:

A manufacturing unit facing equipment breakdowns might use RCA to discover that poor maintenance schedules, rather than overuse, are causing failures.

10. Time Audit Tools

Time audits measure how long tasks and processes take, providing a baseline to evaluate improvements. Tracking apps can automate this process, offering detailed insights.

Popular Tools:

- Toggl

- Clockify

Example:

A project manager auditing a software development process might find that meetings consume 30% of the team’s time, leading to a reduction in frequency and duration of meetings.

11. Total Quality Management (TQM)

TQM is a holistic approach to process improvement that focuses on customer satisfaction, cross-departmental collaboration, and continuous improvement. TQM tools include:

- Control charts to monitor process stability.

- Pareto charts to prioritize issues based on their impact.

Example:

A logistics firm might use control charts to track delivery times and Pareto analysis to address the 20% of issues causing 80% of delays.

12. Agile and Lean Tools

These methodologies prioritize efficiency, adaptability, and eliminating waste. Agile tools like Scrum boards and Lean tools like Kaizen events drive incremental improvements.

Example:

A marketing agency adopting Lean principles might focus on reducing bottlenecks in the creative approval process by scheduling daily check-ins to identify and remove roadblocks.

13. Gantt Charts

Gantt charts visualize project timelines, showing dependencies between tasks and helping teams allocate resources effectively.

Example:

An HR team organizing a company-wide training program could use a Gantt chart to track milestones like session planning, employee registration, and final evaluations.

14. Simulation Tools

Process simulations model workflows digitally to predict the outcomes of proposed changes. Tools like Arena or Simio allow teams to experiment without disrupting live processes.

Example:

A retail company might simulate different store layouts to determine the most efficient setup for customer flow during peak hours.

Selecting the Right Tools

With so many tools and techniques available, it’s essential to choose ones that align with your organization’s goals and culture. For example:

- Small teams may benefit from intuitive tools like Trello or Toggl.

- Enterprises may require advanced platforms like UiPath or Power BI.

The right tools amplify your process improvement efforts, enabling your team to focus on strategy rather than manual tasks. Combined with a structured improvement approach, these tools ensure sustainable results and a competitive edge.

The Role of Technology in Process Improvement

Technology is a cornerstone of modern process improvement, offering tools and capabilities that revolutionize workflows. From automation to predictive analytics, leveraging the right technological solutions can amplify efficiency, reduce human error, and ensure processes remain agile in a rapidly changing business environment.

Automation as a Game-Changer

Automation lies at the heart of technological innovation in process improvement, enabling organizations to achieve more with fewer resources.

- Business Process Automation (BPA):

BPA automates repetitive, manual tasks across workflows. For example, automating customer service ticket routing ensures faster response times and consistent service delivery. By eliminating mundane tasks, BPA frees employees to focus on strategic activities. - Robotic Process Automation (RPA):

RPA uses software bots to mimic human actions like data entry, form filling, and document processing. It’s particularly effective in high-volume, rules-based tasks. For instance, a bank using RPA to reconcile accounts can drastically reduce errors and processing time, leading to faster financial close cycles.

Popular Tools and Platforms

Several tools and platforms empower organizations to implement process improvement seamlessly:

- Monday.com:

A user-friendly project management tool that facilitates workflow customization, team collaboration, and progress tracking. - Pipefy:

A no-code platform that streamlines workflows through visual interfaces, making it accessible to non-technical teams. - Tallyfy:

Simplifies process documentation and automation while offering real-time tracking of workflows for greater transparency. - Integrify:

A low-code platform that focuses on automating HR, finance, IT, and sales processes. It supports integration with existing business systems for smooth implementation.

Emerging Technologies

Beyond automation, cutting-edge technologies are reshaping process improvement strategies:

- AI and Machine Learning:

AI-driven predictive analytics identify potential inefficiencies before they become issues. For example, machine learning algorithms can forecast demand in supply chains, optimizing inventory levels and reducing waste. - IoT (Internet of Things):

IoT devices provide real-time data on processes, such as equipment performance in manufacturing. This data enables proactive maintenance, preventing costly downtime.

Balancing Automation with Accessibility

While automation offers transformative potential, accessibility remains a priority for smaller businesses. Low-code and no-code platforms bridge this gap, allowing organizations with limited technical expertise to implement sophisticated automation solutions without the need for extensive programming knowledge.

Technology isn’t just a tool—it’s a strategic enabler for process improvement. From BPA and RPA to AI and IoT, the right mix of automation and emerging technologies can enhance efficiency, reduce costs, and future-proof your business.

Real-World Case Studies: Process Improvement in Action

The true power of process improvement shines through real-world examples. Let’s explore three compelling case studies across diverse industries, showcasing how targeted improvements drive transformative results.

1. Retail: Automating Inventory Management

- Challenge:

A mid-sized retail chain struggled with inaccurate inventory tracking, leading to stockouts, overstocking, and customer dissatisfaction. Manual processes made inventory updates time-consuming and error-prone. - Solution:

The company implemented a cloud-based inventory management system integrated with IoT-enabled sensors. Real-time data on stock levels allowed automated reordering and prevented human errors in tracking. - Results:

- Reduced inventory costs by 25%.

- Improved order fulfillment accuracy by 30%.

- Increased customer satisfaction due to consistent product availability.

2. Healthcare: Streamlining Patient Onboarding

- Challenge:

A hospital faced delays in patient onboarding due to paperwork-heavy admission processes. This inefficiency led to long wait times, frustrated patients, and overwhelmed staff. - Solution:

By deploying an RPA-based patient onboarding system, the hospital digitized forms, automated insurance verification, and integrated electronic health record (EHR) systems for seamless data entry. - Results:

- Reduced onboarding time by 40%.

- Freed up administrative staff for higher-value tasks.

- Enhanced patient satisfaction scores by 20%.

3. Finance: Digitizing Invoicing Processes

- Challenge:

A multinational finance firm struggled with delayed invoice approvals and payment processing, resulting in late fees and strained vendor relationships. - Solution:

The company adopted a digital invoicing platform with automated approval workflows. Features included OCR (Optical Character Recognition) for digitizing paper invoices and real-time tracking for transparency. - Results:

- Cut invoice processing time by 50%.

- Eliminated late fees, saving $100,000 annually.

- Improved vendor relationships due to faster payments.

From retail to healthcare and finance, these case studies demonstrate the universal value of process improvement. By addressing specific challenges with tailored solutions, organizations can achieve measurable results in efficiency, cost savings, and customer satisfaction.

Avoiding Common Pitfalls in Process Improvement

While process improvement offers significant benefits, many initiatives fail due to avoidable mistakes. Recognizing these pitfalls early can save time, resources, and frustration, ensuring a smoother path to success.

1. Focusing on Symptoms Instead of Root Causes

One of the most common errors is addressing surface-level symptoms rather than the underlying problem. For example, if delivery delays occur, simply hiring more staff without investigating inefficiencies in routing or scheduling will only provide a temporary fix.

- Solution: Use tools like the 5 Whys or Root Cause Analysis to dig deeper and identify the real issues affecting your process.

2. Poor Communication and Lack of Team Buy-In

Process improvement initiatives often fail when teams don’t understand why changes are happening or how they benefit the organization. Resistance to change can undermine even the most well-designed plans.

- Solution: Foster collaboration by involving key stakeholders early in the process. Regular updates and open communication channels ensure everyone is aligned with the goals and benefits of the improvement.

3. Overcomplicating Processes or Relying on the Wrong Technology

Adding unnecessary steps or deploying the wrong tools can create confusion and inefficiency, negating any potential gains.

- Solution: Focus on simplifying workflows. Choose technologies that align with your goals and are user-friendly, especially for non-technical employees.

Avoiding these pitfalls requires a proactive approach: identify root causes, communicate effectively, and keep improvements simple and relevant. With the right strategy, your initiatives can deliver lasting results.

5 Quick Tips to Master Process Improvement

Mastering process improvement doesn’t have to be daunting. These actionable tips will help you navigate the journey effectively while building momentum for long-term success.

1. Start Small with a Single Process

Focus on improving one manageable process before tackling larger, more complex workflows. For instance, optimizing employee onboarding can serve as a low-risk starting point that yields immediate benefits.

2. Build a Detailed Plan and Document Every Step

A clear plan ensures everyone understands the scope, timelines, and expected outcomes of the improvement. Documenting steps helps maintain transparency and provides a reference for scaling efforts.

3. Engage Employees for Feedback and Buy-In

Frontline employees often have the best insights into inefficiencies. Involve them early, encourage suggestions, and celebrate wins to foster a culture of collaboration and accountability.

4. Focus on Measurable Outcomes

Establish specific KPIs to track progress and success. Whether it’s reducing processing time by 20% or cutting costs by $50,000 annually, measurable outcomes keep your efforts grounded and impactful.

5. Embrace a Culture of Continuous Improvement

Improvement isn’t a one-time project; it’s an ongoing journey. Encourage teams to regularly assess processes, identify opportunities, and adapt to changes in the business environment.

By starting small, engaging employees, and focusing on measurable results, you can master process improvement while embedding it into your organization’s DNA. Continuous improvement isn’t just a goal—it’s a mindset.

Conclusion: Process Improvement as a Competitive Advantage

Process improvement isn’t just a one-time project; it’s a transformative strategy that can elevate your organization’s efficiency, productivity, and competitiveness. By leveraging methodologies like Lean or Six Sigma, embracing technology, and avoiding common pitfalls, businesses can unlock measurable gains and stay ahead of market demands.

The long-term value of continuous improvement lies in its adaptability. Markets evolve, customer needs change, and businesses must be agile to thrive. A culture of ongoing improvement ensures your organization remains resilient, efficient, and ready to tackle challenges proactively.

Key Takeaways:

- Focus on understanding root causes and simplifying workflows.

- Use technology to streamline processes and reduce waste.

- Engage employees to create buy-in and sustain changes.

- Measure success through clear KPIs and continuously refine processes.

Now it’s your turn. Start by assessing your workflows and identifying bottlenecks or inefficiencies. Involve your teams, choose the right methodologies, and begin implementing small, measurable changes. The journey toward process improvement is a step-by-step transformation, but every step takes you closer to operational excellence and growth.

The tools, insights, and strategies shared here are your starting point. What will you improve first?

FAQ: Common Questions About Process Improvement

What is the first step in process improvement?

The first step is identifying the process that needs improvement. Start by evaluating workflows with measurable inefficiencies, such as delays, errors, or high costs.

How long does process improvement take?

Timelines vary depending on the complexity of the process and scope of change. A small-scale improvement might take weeks, while larger projects may require months or ongoing efforts for continuous refinement.

Which methodology is best for process improvement?

It depends on your goals. Lean focuses on waste reduction, Six Sigma targets defect elimination, and Kaizen emphasizes incremental changes. Evaluate your organization’s needs to choose the best fit.

How does technology support process improvement?

Technology enables automation, predictive analytics, and real-time monitoring. Tools like Monday.com and Pipefy simplify workflows, while RPA and AI enhance efficiency and accuracy.

How can I get buy-in for process improvement initiatives?

Involve employees early, communicate the benefits clearly, and demonstrate how changes align with organizational goals. Celebrate small wins to build momentum.

Is process improvement only for large organizations?

No, businesses of all sizes benefit from process improvement. Scalable tools and methodologies like no-code platforms make it accessible for startups and SMEs as well.

What is the biggest mistake in process improvement?

The most common mistake is focusing on symptoms rather than root causes. Always dig deeper to identify and address the core issues in your processes.