Table of Contents

The Everlasting Appeal of PDCA

In the world of continuous improvement and quality management, the PDCA cycle—short for Plan-Do-Check-Act—stands as a cornerstone methodology. Developed in the early 20th century, PDCA has remained a critical tool for streamlining processes and enhancing productivity across various industries. Originally conceptualized by Walter A. Shewhart and later popularized by W. Edwards Deming, PDCA provides a systematic framework for solving problems and implementing change effectively.

The cycle’s enduring appeal lies in its simplicity and effectiveness, which have proven beneficial for giants like Toyota, Nike, and the Mayo Clinic. These organizations have leveraged PDCA to refine operational processes, reduce inefficiencies, and foster innovation, cementing its status as an indispensable strategy in modern business management.

The Origins of PDCA: From Shewhart to Deming

The PDCA cycle has its roots in the early 20th century with the pioneering work of statistician Walter A. Shewhart. Known as the “Shewhart Cycle,” the original concept revolved around improving product quality through a methodical approach of hypothesis, testing, evaluation, and action. Shewhart’s work primarily focused on improving manufacturing processes and product quality, laying the groundwork for systematic process improvement.

W. Edwards Deming, a prominent figure in the world of quality management, refined Shewhart’s ideas into the four-step PDCA cycle we recognize today. Deming’s adaptation emphasized the importance of continuous feedback and iterative improvement. After World War II, Deming introduced this methodology to Japanese industries, which were eager to rebuild and enhance their manufacturing capabilities. As a result, companies like Toyota adopted PDCA, leading to significant advancements in quality and efficiency.

The cycle’s foundation in the scientific method is one of its greatest strengths. By hypothesizing solutions, testing them in a controlled environment, evaluating outcomes, and acting based on the results, PDCA ensures a disciplined approach to problem-solving that is both logical and effective.

Breaking Down the Four Stages of PDCA

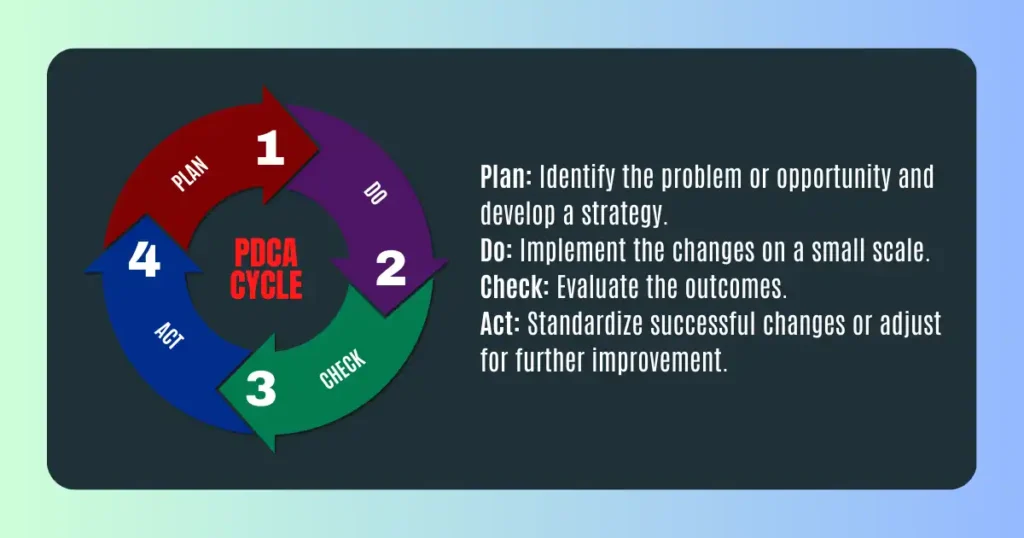

Understanding the PDCA cycle requires delving into its four distinct stages, each crucial for effective implementation and continuous improvement.

Plan

The first step, Plan, involves identifying a problem or opportunity and developing a comprehensive strategy to address it. This stage requires thorough research and analysis to understand the issue at hand and set clear objectives. For instance, a company might gather customer feedback to pinpoint desired product features, which can then guide the planning of new product developments.

Do

Once a plan is in place, the Do phase involves executing the proposed changes on a small scale. This controlled implementation allows for practical observation and minimizes risk. An example could be a company launching a pilot program within a specific department to test a new workflow or process. This stage is about action and observation, ensuring that all aspects of the plan are put into practice accurately.

Check

Following the implementation, the Check stage focuses on evaluating the outcomes. This involves collecting and analyzing data to determine whether the changes have achieved the desired effect. For example, after introducing a new process, a business might analyze productivity metrics and employee feedback to assess its success. The Check phase is crucial for understanding the efficacy of the changes and identifying areas for further refinement.

Act

Finally, the Act stage concludes the cycle by deciding whether to standardize the successful changes or revisit the process for further iteration. If the results are positive, the new process is implemented on a broader scale. Conversely, if improvements are needed, insights gained during the Check phase guide the next cycle. This iterative approach fosters continuous improvement, as seen in Toyota’s renowned Kaizen practices, where small, incremental changes lead to significant overall improvements.

Real-world examples abound, demonstrating PDCA’s utility across industries. Toyota’s commitment to continuous improvement through PDCA has helped it streamline operations and enhance product quality. Similarly, Nike’s lean initiatives have leveraged the cycle to optimize supply chain efficiency, while the Mayo Clinic has used PDCA to reduce patient wait times and improve healthcare delivery.

The PDCA Cycle’s Modern Applications

Today, the PDCA cycle is as relevant as ever, finding applications across diverse industries and scenarios. In manufacturing, companies like Toyota have integrated PDCA into their lean production systems, achieving remarkable efficiency and quality control. Their continuous improvement culture, driven by PDCA, has set a global standard for manufacturing excellence.

In healthcare, institutions like the Mayo Clinic have adopted PDCA to streamline operations and enhance patient care. By applying the cycle to reduce wait times and optimize resource allocation, healthcare providers can improve service delivery and patient satisfaction.

The tech industry also benefits from PDCA’s systematic approach, especially within agile software development frameworks. By iterating through cycles of planning, execution, review, and adjustment, tech companies can rapidly adapt to changing market demands and technological advancements.

Moreover, PDCA aligns seamlessly with methodologies like Six Sigma, Lean, and Kaizen, providing a robust framework for process optimization and quality management. Startups and innovators use iterative cycles like Build-Measure-Learn, which mirror PDCA principles, to foster agility and innovation.

PDCA vs. PDSA: The Subtle Difference

While PDCA is widely recognized, a variation known as PDSA—Plan-Do-Study-Act—offers a subtle yet significant difference. The distinction lies in the third stage: “Check” in PDCA versus “Study” in PDSA. While “Check” emphasizes data evaluation to determine whether objectives have been met, “Study” involves a deeper analysis of the data to extract broader insights and learning.

Certain industries prefer PDSA for its focus on understanding and learning from results, rather than solely verifying objectives. For example, healthcare and education sectors often favor PDSA for its emphasis on holistic analysis and continuous learning, which can lead to more profound and meaningful improvements.

Both PDCA and PDSA share the same fundamental principles of iterative improvement and systematic problem-solving. However, the choice between them depends on an organization’s specific needs and objectives, as well as the industry context in which they operate.

Overcoming Common Challenges in PDCA Implementation

Implementing the PDCA cycle can transform an organization’s approach to continuous improvement, but it does come with challenges. One of the most significant barriers is resistance to change. Employees often feel comfortable with existing processes and may resist new methods that disrupt their routine. Overcoming this requires effective communication and team involvement. By clearly articulating the benefits of PDCA and involving team members in each phase, organizations can foster a culture that embraces change.

Another common hurdle is inadequate data collection during the “Check” phase. Without reliable data, it’s impossible to accurately assess the success of implemented changes. To counter this, organizations should prioritize robust data collection methods, utilizing both qualitative and quantitative metrics. Training staff on data collection tools and techniques ensures that the information gathered is both comprehensive and accurate.

The inconsistent application of the “Act” phase is another challenge. Often, organizations fail to standardize successful changes or revert to old habits if immediate results aren’t evident. To address this, it’s crucial to focus on incremental improvements over dramatic changes. Small, manageable adjustments are easier to implement and sustain, leading to long-term benefits.

Additionally, employing structured problem-solving tools like A3 thinking can help teams visualize the entire PDCA process, ensuring a systematic approach. A3 thinking encourages clarity and focus, guiding teams through problem identification and solution implementation effectively.

By addressing these challenges with strategic planning and a commitment to continuous learning, organizations can harness the full potential of the PDCA cycle for sustained improvement.

PDCA in the Age of Digital Transformation

As we move deeper into the digital age, the PDCA cycle is evolving to leverage new technologies, enhancing its effectiveness and efficiency. One of the key adaptations is the use of advanced data analytics in the “Check” phase. By harnessing big data and predictive analytics, companies can gain deeper insights into process performance, enabling more informed decision-making.

In the “Do” phase, automation tools are revolutionizing execution speed. Automation reduces manual effort and increases process accuracy, allowing for quicker implementation and iteration. This is particularly beneficial in fast-paced industries where time-to-market is critical.

Moreover, artificial intelligence (AI) and machine learning (ML) are being integrated into the PDCA process to enhance predictive capabilities and streamline operations. AI can identify patterns and predict outcomes, providing valuable insights that guide each phase of the cycle. For instance, a tech company might use AI to analyze customer feedback rapidly, allowing for iterative software updates that improve user experience.

A compelling case study is that of a tech company using PDCA to drive iterative improvements in customer experience. By employing AI-driven analytics, the company continuously gathers and analyzes customer data, implementing changes that enhance usability and satisfaction. This iterative approach not only improves the product but also fosters a customer-centric culture that aligns with modern business demands.

As digital transformation continues to reshape industries, PDCA remains a vital tool, adaptable to new technologies and methodologies that drive success in an ever-evolving landscape.

Why PDCA Remains a Powerful Tool for Success

The PDCA cycle stands as a testament to the power of structured, iterative improvement. Its simplicity and adaptability make it invaluable across diverse industries, driving quality enhancement and operational efficiency. By embracing PDCA, organizations not only tackle current challenges but also build a foundation for sustained growth.

As you consider the potential of PDCA in your own projects or workplace, remember that incremental, consistent application can lead to substantial improvements over time. Start small, involve your team, and remain open to learning and adaptation.

In the words of W. Edwards Deming, “It is not necessary to change. Survival is not mandatory.” Let this serve as a reminder of the importance of continuous growth and adaptation in achieving long-term success.