Table of Contents

Root cause analysis, or RCA for short, is an extremely powerful technique and set of tools which can reap significant rewards for your organisation – and I mean significant! It is one of those approaches that, if they get it right, businesses will utilise again and again when the time requires it.

In this article, we want you to understand the benefits of root cause analysis, and the power it can warrant over your people, problems and processes – an extremely positive power. (Notice the word extremely being used several times here – this is the word that naturally comes to mind when discussing this topic as some of the rewards of root cause analysis can be on the “extremely” positive side).

We want to use this article to introduce you to the process. Delivering effective root cause work does not just mean delivering a tool – there is much more to it than that. There is a process. We will also look at the fundamentals of the technique, introduce some of the main tools and give you enough insight into this technique to leave this article confident that you want to explore and expand this knowledge further.

The fundamentals of root cause analysis

What is root cause analysis?

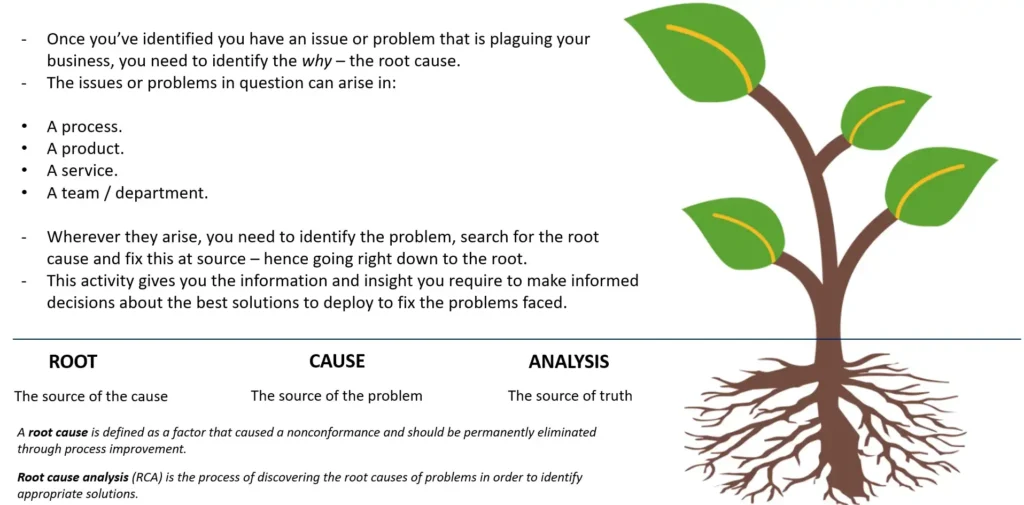

To understand this, I am going to start off with a couple of concise definitions of the term root cause analysis. For root cause, we have: “A root cause is defined as a factor that caused a nonconformance and should be permanently eliminated through process improvement”. For root cause analysis we have: “root cause analysis is the process of discovering the root causes of problems in order to identify appropriate solutions”. Let us break these definitions down a bit.

Root cause

The root cause is the absolute start of a problem. If you think about a plant, you have looked at the leaves, examined the stem, followed this down to the earth and the dirt, have continued down into the dirt, down the roots until you get to the very tip of the plant – the empty seed shell where the plant first started. This is the root cause of your plant, and this is what we mean by root cause.

When it comes to a problem we are facing, we have to, first of all, identify the problem (the plant), examine the problem in more detail and work back (the leaves, the stem, the dirt) to start to see the root causes (the roots). There may be a number of potential root causes you could go down but, ultimately, there will be one root cause you land on and say yes, this is the final actual root cause (the seedling). When faced with a problem, you identify it exists and then you work back, going further and further back until you get to where it all started.

Root Cause Analysis

When it comes to root cause analysis, here we are simply referring to the process that you follow in order to get to that final root cause. This will be where you examine the leaves, the stem, the dirt and the various roots of your plant, in order to get to that final actual cause. This process is where you conduct your analysis, you seek to not only understand that a problem has indeed occurred, but why it has occurred. This effort takes some investigation, as you cannot simply say what you think is the root cause.

As part of this effort, you may identify a range of potential root causes, but you must ultimately use this process to get you to the final actual root cause. Without this certainty, you lose the ability to make informed decisions on what the solution to your problem should be and therefore could deliver solutions which don’t tackle the actual root cause. Therefore this process is all about giving you certainty and clarity above all else.

Indications a root cause analysis exercise is needed

There are a number of ways in which you can identify confidently a root cause analysis exercise is indeed required. These are known as indicators, and they are everywhere, acting as usual pointers and directors not only that a root cause analysis exercise is needed, but for which problem and where this is occurring.

Indicators can include:

- A process is taking much longer to complete than it once was.

- You are seeing customer complaints rise.

- The quality of a certain product or service has been declining.

- Employee turnover is on the rise.

- You are seeing errors coming out of a system time and time again.

If you see any of these types of things happening, they could indicate that something has or is going wrong and needs to be investigated with a root cause analysis initiative.

Remember. These indicators can be both short-term and long-term indicators. Short-term could be something that has quickly happened, such as on average you would get 30 products to market per week now it is 10, all of a sudden, one week later. This could indicate that there has been a material change on the ground that should be fixable relatively quickly.

Long-term could be something happening over a period of time. Every 6 months you conduct your customer satisfaction survey and each time it has come back over the past 2 years it has been getting lower and lower and lower. This could indicate there is a systematic problem that needs addressing. The problem with these types of instances can often be that they are hard to spot, and they don’t have obvious indicators. With these, they can often be doing a lot of damage without you knowing, whether that be to processes, mindsets or the future potential of your business.

If you are addressing a long-term or a short-term problem could impact the approach you take, the tool you deploy and the technique you choose, so it is good to be mindful of this.

Also read: When is root cause analysis required?

The role of risk

It is also worth noting at this stage the role risk plays in the topic of root cause analysis. Root cause analysis can be used to both address risk and prevent risk. If you think about root cause analysis from the two sides of the coin, we can use root cause analysis both reactively and proactively, and risk plays a big part in that.

Risk is one of those strange things that organisations will have mixed feelings about. Some organisations love risk, embrace risk and take risks on a daily basis, seeing it as one of those things that, if it pays off, it can pay off BIG. Other organisations fear risk, try to avoid it, and do everything in their power to minimise both their exposure to it and its impact on their business.

These approaches make sense, and risk can indeed both help and hinder a business, so caution is always advised. When it comes to the role root cause analysis plays with risk, we can tackle this topic in the following way.

Reactive response to risk

When something happens unexpectedly in your business, the risk around this increases. This could be the risk of it occurring again, of it spreading to other areas of the business and impacting them or the risk of the effects of this problem getting worse and worse over time. Effectively, by something going wrong so suddenly, the negative ripple effect you see across the business can be swift and very damaging. Therefore, root cause analysis is needed here to identify the problem, identify the cause and identify the fix, quickly! This is a reactive response to something which has occurred unexpectedly.

Proactive response to risk

On the flip side, sometimes you want to get ahead of the problem or the risk from occurring in the first place. There are a range of root cause analysis tools and approaches that can help you to do this – think through the risk, the impacts and the required solutions before they have even begun. This work can empower you to put effective controls in your processes today, helping you to avoid any of the unforeseen but potential problems from ever occurring.

This kind of work will often be done when you are building out a new process from scratch, or you are reforming, redesigning or reengineering a process for the future. In these instances, you are seeking to ensure processes don’t falter as soon as they go live, that they are built for the future and that they learn the mistakes of times gone by. That is one of the really important aspects of root cause analysis to remember – a root cause identified and a solution delivered then becomes a lesson learned and knowledge to be shared.

The purpose of root cause analysis

Root cause analysis has a key and obvious central purpose – to conduct extensive analysis to enable you to land on a final root cause. Outside of this obvious purpose, there are a range of other purposes associated with root cause analysis.

Firstly, it enables you to generate not just one actual root cause, but many potential root causes. Running through the process and using the tools to do this gives you confidence that the actual root cause you land on is indeed the correct one because you have isolated and removed all of the rest. This is a level of confidence leaders want in root cause analysis work conducted, as many decisions can be made from this one simple root cause being identified.

Secondly, root cause analysis can empower people within your organisation. It can empower people to report that something has gone wrong because they know some sort of action will come from this reporting. Also, it empowers the individual to help in the search for solutions and in the efforts to deploy them, as what they have reported directly impacts them.

Thirdly, as we have covered already, root cause analysis helps in the reduction and removal of risk, both current and potential future risk. Therefore, when seeking to conduct a root cause analysis exercise, don’t just focus on one purpose, try to realise the benefits of all purposes.

The benefits of root cause analysis

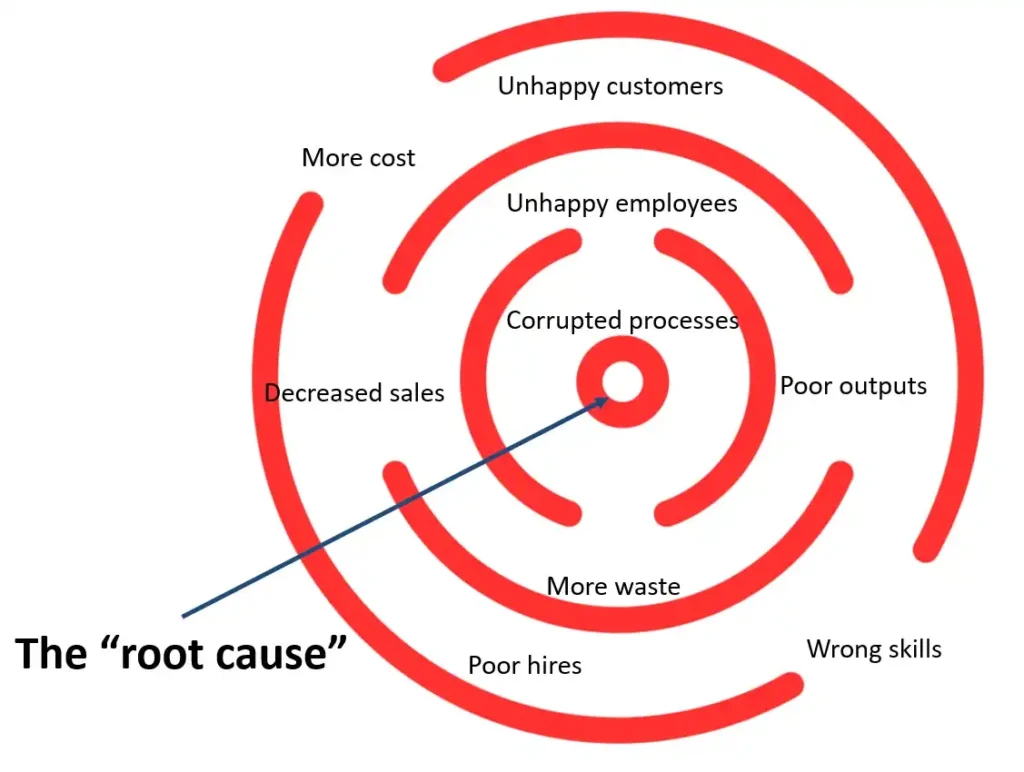

The ripple effect

One of the biggest benefits of root cause analysis I refer to as the ripple effect. The concept is simple. When something is going wrong within your organisation, this has a ripple effect across other departments, processes and teams not directly involved. The ripple effect starts with the root cause of the problem, and then negatively starts to impact other parts of the business. We can see delays, lost sales, increased waiting time and costs. These things often will have their own direct root causes, but all stemming from the original root cause which is now rippling across the business.

From a root cause analysis perspective, you can flip this. Root cause analysis can lead to a positive ripple effect across the business, with the knowledge and insight rippling out across the business. By this we mean you are giving yourself and your business greater insight into not only what has gone wrong, but why it has gone wrong, where else it could possibly fail and other additional problems and effects that can arise from this. By knowing this information, you can turn those negative ripple effects across the business into positive, ones by making the appropriate changes, delivering effective solutions and being forced to reform teams, procedures and processes in light of what has gone wrong.

When it comes to root cause analysis, try and flip the mindset. Rather than saying “damn, something has gone wrong and we need to fix it to stop X”, try saying “OK, something has gone wrong and so now we have an opportunity to improve and influence X”.

Specific benefits

When it comes to launching a root cause initiative in your business (depending on how big or widespread your problem is / your initiative is going to be) you may need to secure buy-in from leadership. If your initiative is going to cause disruption, lead to large-scale change or require some financial or time commitment, your leaders will want to know the benefits of conducting this work, in this way, outside of the obvious benefits (fixing what has gone wrong). There are a range of benefits you can cite including:

- Gives you insight & information. Both the process of conducting this activity and the output give you something you did not have prior. It enables you to make informed decisions as the process concludes and you have all of the relevant information you need. Too many times people make ill-informed or uninformed decisions, leading to the wrong solutions being chosen for the wrong problems. This work can help you to avoid such outcomes.

- Protects your organisation. Whether your people, processes, systems or customers, finding problems, and root causing and fixing them for the long term is crucial. If you deliver such work correctly, you can secure your operational performance for some considerable time to come. Remember, think about the purpose of this work outside of the ordinary. Just as something bad occurring today can have longer-term ramifications for your business, so too can good things. Good changes made today can be felt long into the future.

- Gives you confidence and speedier delivery. Having the information this type of work gives you can help give you confidence in your solutions, in how you sell it to your leaders and the way forward. It also enables you to deliver solutions quicker and makes you more reactive, as you do not need to validate if your approach is correct. Many times people can get bogged down trying to find more information and insight, trying to validate the solutions they have identified in solo. By deploying the root cause analysis process in full, you can avoid this as you have all of the relevant information you need upfront.

- Guarantees and improves quality. By ensuring issues do not arise in your processes, you are also ensuring they don’t impact your products and services. One of the key ways in which people identify a root cause analysis initiative is needed is by product and service quality being negatively impacted, leading to a rise in customer complaints and a hit to sales. The reduction of such problems can also feed up time for employees to focus on the quality of the products and services already there, leading to that positive ripple effect we mentioned earlier.

- Save you money. Errors cost money – in sales, the cost of fixing, the cost of dealing with complaints (handling and compensation/refunds), the cost of finding the solutions etc. It goes without saying – reduce the number of errors you have and reduce the cost of having to handle them. As with the positive ripple effect, you can now flip this and invest more of this (what would be wasted) money into the products and services already there, boosting sales and customer satisfaction.

- Reduces employee & customer turnover. A constantly breaking process, flawed products leading to complaints and the handling of said complaints will frustrate your employees. They will grow tired of having to repeat the same well-trodden path of fixing something in the same way again and again. Equally, clients who receive constant problems with their products and services purchased will end up turning their back on your company and the offerings you have. This increased turnover in terms of employees will cost you in terms of lost knowledge, training, onboarding and recruiting costs. The turnover in clients and customers will cost you in terms of lost sales and potential brand and reputational damage.

- Saves you time. Just like with money, errors cost you time, and by root-causing your most common and troublesome problems, you can reduce their recurrence and the time taken to handle these. One simple error can lead to that well-known ripple effect across your business, with time wasted not only fixing the problem but also having to root cause it and collect that much-needed insight and information. Again, this is all time that could be reinvested back into the business to improve quality, satisfaction and performance.

- Reduces risk. Tied to all of these is risk, as we have mentioned previously. Root cause analysis is a big helper in the reduction of risk, both immediate and long-term risks, current and potential risks. Root cause analysis empowers you to be both reactive and proactive with how you approach this problem, by addressing what you face today and what you could face tomorrow. The brilliant thing about root cause analysis tackling risk is that the ripple effect of this is probably the greatest, as you instantly and then longer-term save the business money, and time, reduce turnover of clients and employees, protect processes and procedures and set your organisation up for the future.

Examples of root cause analysis

To help you to understand what root cause analysis is, and how to spot the need for it and deploy it still further, I will provide you with a number of practical examples. These examples are indeed the most common types of root cause analysis out there, and by understanding these, you could easily start conducting some of these right away.

Process related problem

You have a manufacturing-based process producing car parts for your clients who are responsible for the construction of the final car products. This process has, of late, been producing a number of issues. Many of the car parts have been leaving your process/factory with quality issues, and these issues range from damage to incorrect colour, incorrect parts or the wrong size. Therefore, from this initial understanding, we know that something is wrong within the process that precedes the final product output.

In this scenario, a root cause analysis exercise would be needed to understand where in the process the problem is stemming from, so we can identify what the root cause actually is and find a permanent fix for it. As we have specific quality issues coming out on specific products, we will be able to see clearly the impact of any changes and solutions we deploy, and the testing that sits around this. Outcomes from this work could include the removal or reforming of process steps, delivering a new solution or putting strong controls in place to ensure the problems do not occur again.

Being a process-related problem, you can amend steps, test new ones and remove potentially defective ones and see the benefits of doing all of this, so as long as you test this in a controlled environment (and not with live products being shipped) you should be able to land on the relevant changes needed, confidently.

People related problem

We have another process which has been checked and this process is working perfectly. We did some work on the process previously, leaned it out, and have seen improvements to how the process is delivered. However, we are still seeing varying outputs from the process, with the products produced being done so in different timeframes, with different quality levels and, ultimately, by different people. This could indicate we have an issue with the people who are working in the process.

In this scenario, a root cause analysis exercise would be needed to understand exactly what it is about the people running the process that is actually going wrong. Are we seeing a training issue? Are we seeing only certain individuals causing issues and others not? Is there a geographical split (the US performing better than the UK, for example)? This root cause work would not only identify the cause of the problem but could segment it as necessary.

Potential outcomes from this type of work could include standardising the working practices of the teams, improving the training offered to the teams or focusing on specific individuals through performance improvement plans. You could also look to change roles and responsibilities, reduce the manual nature of the work (if this is having a detrimental impact on the individuals) or ensure that new starters into the team are all trained in the same way, by the same person. The best practice is shared across teams is often a common response here too.

System-related problem

We have a Payroll Process which has recently seen a surge in errors coming from the process. These errors are costing the team significant amounts of time to investigate and fix, as well as handling the complaints that are arising because of them. These errors are hitting specific parts of the overall payroll operations, and therefore we can deduce early on that this issue may be targeted or specific to one area.

In this scenario, a root cause analysis exercise would be required to understand exactly where this cause is coming from, working back from the errors we are seeing, the analysis that is being conducted on said errors and finding that final cause. If we go back far enough, we can see this particular set of errors is coming from the systems which the Payroll Team are using to run the monthly payroll. The system is generating incorrect data, which is being used in other systems and causing incorrect outputs.

If we dive even further back, we can see that the reason for this incorrect data is that an integration in the source system has failed and is not pulling the correct data over into the Payroll System. The issue with the integration can now be handled by the IT Team to fix, but again, you have successfully identified the root cause and can now deploy the right fixes to this issue.

Indicators root cause analysis is needed

As well as these examples, there can be a range of reasons as to why a root cause analysis exercise is indeed needed. It is with confidence that one could say a root cause analysis is required when something is happening in your business that you cannot really explain. Something has shifted in a process or team which is impacting performance in a negative way, which means there is something defective which needs investigating and fixing.

Even though this is the case, it is important to know what the indicators are so that a root cause analysis is indeed required. These can include (but are not exclusive to):

- SLAs are not being adhered to

- KPIs are being missed

- Sales are dropping

- Customer satisfaction is falling

- Customer complaints are rising

- Employee turnover is rising

- Processes are taking longer to deliver

- Processes are costing more to deliver

- Budgets are overspending

If you see any of these indicators occurring within your organisation and you are not 100% confident as to why, this tells you a root cause analysis exercise is needed.

Also Read: How to run a Root Cause Analysis Workshop?

Root Cause Analysis document

One important activity you should be conducting that needs to be called out is the building of your root cause analysis document. Not everyone does this when conducting a root cause analysis, but it can be a very helpful right of passage to complete. Remember, conducting a root cause analysis is not simply about completing a tool, identifying the cause and walking away. There is a whole process that sits around root cause analysis, and because of this, documenting how this is done is really important.

Why? Here you want to ensure everything is easily accessible from one place. It will be a live document that people can visit to see the progress of your initiative. It’ll ensure all progress is tracked correctly by updating as you do the work, and therefore not forgetting what has been done when you revisit the document to populate it in 3 months. Furthermore, you can use the document to learn the lessons of this root cause work in the future, as more related problems arise and you want to educate yourself on what you and others did before.

Therefore, when it comes to identifying a problem, establishing the root cause and deploying your solutions – record them.

Also read: Root cause analysis in manufacturing: A case study

Other root cause analysis considerations

When it comes to discussing root cause analysis, there are a range of other considerations that must be covered which many people often omit. Outside of the theory, the methodologies and the tools, root cause analysis is a complex topic that needs to be unpacked further if you are to truly understand and successfully deploy it.

Reactive vs. proactive RCA

Root cause analysis can be deployed in two ways for two different purposes – deployed reactively because something has gone wrong and needs fixing there and then, or proactively, ahead of something potentially going wrong to try and ensure it does not go wrong at all.

With reactive root cause analysis, this is conducted when you find yourself having to react to something. Something has gone wrong and you are unsure why, you can only see the problem and its effects. In this instance, you are now having to react to what has gone wrong, calling upon root cause analysis to find this out. In this instance, time is of the essence, and you’ll want a quick turnaround time, looking at the data, the effects and the potential solutions, before delivering swiftly your set of solutions. The tools you would often call upon here include the Pareto Chart, Fishbone Diagram or 5 Whys Diagram.

With proactive root cause analysis, this is conducted when you find yourself with the time and space to be able to think ahead of the challenges and issues which may arise. At this stage, nothing has necessarily gone wrong, and nothing is necessarily going to go wrong – but you want to work now to ensure that remains true. How can you put the right controls, the right activities and the right actions in place today to ensure that your processes and operations remain problem and defect-free? Here you have the space and time to think through all potential problems, eventualities and potential solutions needed.

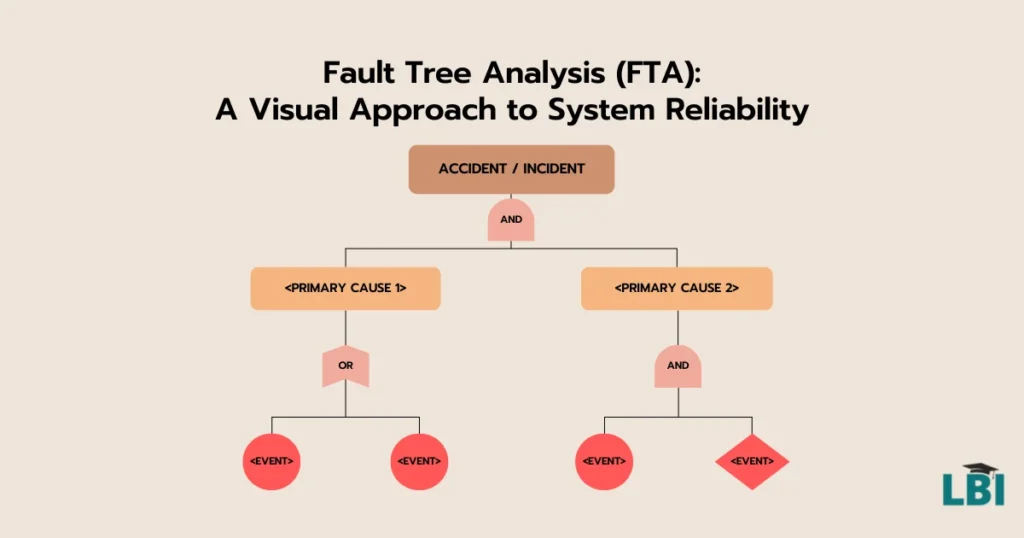

The proactive type of approach is often adopted when you are redesigning or designing from scratch a process, and you want to build/reform the process in a way which protects it in the future. This sort of approach requires tools such as the FMEA, Fault Tree Analysis or indeed your Issue/Errors logs. The latter can be used as you can learn the lessons of what has come before.

Also Read: How do you run a root cause analysis meeting?

Types of causes

When you go searching for the causes of the problems you are seeing, you will often be able to band these into certain groupings which are often linked to wider problems, specific solutions or tools. These types of causes can be banded into 6 main categories including:

Human

In my experience, humans can be responsible for up to 80% of the problems caused within business. Indeed, human responsibility can be found in all causes, as it is often the human that is the initiator. If a system goes wrong, did the human input the wrong information? If an automated bot goes wrong, did the human not initiate it properly? If a product is delayed, did the human not listen well enough during their training and therefore can’t deliver the product on time?

You see, even if the cause of the service is technical, training or data, underlying that is often a human. Types of human-related causes can also include not checking data correctly, initiating the wrong process, not reading directions, misreading something, using the wrong materials or ingredients etc. Human-caused errors are where a human has or has not done something which leads to a train reaction which enables the following process or schedule of activities to be disrupted in some way.

Common ways for these sorts of errors to be reduced include putting peer reviews into processes (where others check your work – however this leads to increased waste) a system/bot automatically checking the work the human has done or the human endeavours to get the process the right first time, in some way.

Environment

By environment, we are referring to your physical or digital surroundings. This is the location or space where you conduct your work, interact with your colleagues and create the products or services you deploy. Some environmental causes are often really tricky to avoid if they are weather or location-related. However, some are easier to influence and impact.

Types of environment-related causes include your office layout not being the best set up from a productivity perspective, health and safety issues in your physical environment, the digital workspace you operate in being messy and uncooperative and any instructions used for the digital workspace being confused and unhelpful. In these instances, the set-up is what causes your problems, as they are more likely to impact the people and processes which operate within them. This is often where ripple effects can be seen in a business.

Often, to address such issues, organizations will deploy the 5S method. This is a highly effective tool where you analyse your current physical or digital set-up, sort everything in order, spruce and shine them and repeat this continually to ensure that problems cannot repeat and lessons are learned.

Organization

When it comes to organization, we are referring to any organizational or company-related factors that could be leading to your problems. These are the direct causes of your most acute issues. Types of organizational-related causes can include the company culture being toxic and negative, leading to mistakes commonly being made. The business is not keeping up with market trends and developments, therefore it is incorrectly delivering activities that are not needed. An organization that does not have a root cause analysis mindset, therefore when things go wrong they are complained about but are rarely fixed. There could be a blame culture in the organization, and the time spent blaming is time not spent fixing.

Whichever it is, it is crucial your organization works in a way which is conducive to good root cause analysis activities, whether that be the delivery of work to avoid or fix when such issues arise.

Process

One of the biggest ways in which processes can lead to problems which need to be root-caused is, as time moves on, processes grow and are left unattended, they become bloated, wasteful and problematic. Processes that are no longer fit for purpose, that can’t serve the needs of the operation effectively enough and that can’t deliver what is expected and when will often lead to problems. These problems are related to time delays, quality issues or unexpected outputs.

Types of process-related causes include no clarity around activities to be completed (confusion around what to do is a big cause of issues seen), changes to the process impacting the final delivery of service not being effectively communicated or, overtime, rework loops being built into your processes causing bottlenecks and waste. The biggest takeaway here is it is often not the process itself that is the problem, it is its evolution, the waste that others add to it or the changing needs and demands of the business/market.

Technology

With technology, we are referring to the systems and tools that we use to deliver the services and products of our business. Technology acts as the framework from which so much of our organization’s operations hang, it ties much of what is done together and, therefore is a critical piece of your business that you need to get right. Technology mistakes are one of those that if severe enough can lead to significant ripple effects across the business (missed deadlines, late products, customer complaints etc.)

Types of technology-related causes can include the system breaking down, the system not being fit for purpose or the requirements that have been added into the system are incorrect, and therefore don’t compute with the system’s needs. You may also have a product that gives you incorrect information and or directions or the technology defaults and begins doing things not expected of it.

Many times, these types of causes can have a deeper root cause, such as incorrect coding, incorrect inputs, overheating of manufacturing systems, checks that have not been done on wiring in a long time etc.

Data

With data, we are referring to the use of data, numbers and information in a range of settings across our business. This could be in our processes, technology, teams, the metrics we use to measure performance, to make decisions etc. When data fails us in any way, this can lead to a range of issues, including decisions being made with wrong data (therefore, incorrect decisions being made), organisations don’t know the true extent of their performance, performance figures hiding underlying issues, systems break as the data inputted into them is not compatible with the system.

Whichever problems you are facing, there could be a range of causes for this. The wrong data may have been provided by someone not fully in the know. The data going into the system is incorrect and leads to a contradicting sequence within the system. Incorrect decisions have been made based on bad data leading to further bad decisions, compounding the cause and the problem.

As data is critical to your business and is produced by humans, processes and technology alike, it is really important to see this type of cause as linked to the other potential causes.

Conclusion

Root cause analysis is a powerful approach which, if delivered correctly, can reap huge benefits for you and your organisation. There are a range of tools and methodologies associated with root cause analysis which are tried and tested and are there to steer you in the right direction. Whether you are following the 8D process or are delivering the Fishbone or 5 Whys Diagram, these will all help you land on exactly what the cause of your most pressing problems is.