Table of Contents

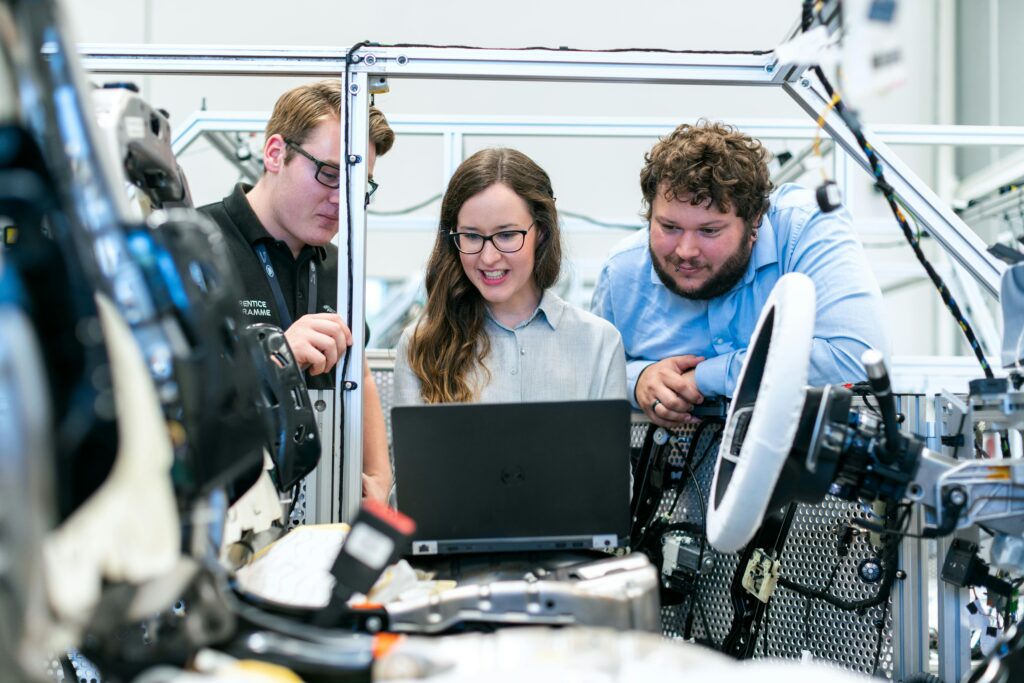

Lean Six Sigma in Research & Design: Why It Matters

Product lifecycles are short, and design rework is expensive. Lean strips out waiting and duplicate effort; Six Sigma squeezes defects and variation. Together they give R&D teams speed and predictability.

- Lead-time wins: A Kaizen Institute case cut project lead time by 50 % and engineering effort 22 %. – Kaizen Consulting

- Labor savings: Boeing’s forward-fuselage redesign trimmed work content 48 %. – MIT OpenCourseWare

- Cycle-time collapse: GlaxoSmithKline slashed a development cycle from 120 days to 30 days — a 75 % drop. – Oriental Journal of Chemistry

Lean Tools Every R&D Team Can Use

- Value-stream map concept-to-launch — expose queues between design, test, and manufacturing.

- Obeya rooms — one visual board for milestones, risks, and rapid countermeasures.

- Set-based concurrent engineering — compare options in parallel instead of endless serial trials.

- 5S digital libraries — single source for CAD, test data, and lessons learned.

Six Sigma Methods for R&D Metrics

| Metric | Track | Benefit |

|---|---|---|

| Time-to-market | Weeks from concept freeze to launch | Reveals bottlenecks |

| First-pass yield (FPY) | % prototypes that meet spec at first build | Flags design quality |

| Engineering change rate | Changes per 1 000 drawing releases | Quantifies late rework |

| Cost variance | Actual vs. target design cost | Keeps projects on budget |

DMAIC gives each metric a path from baseline to controlled improvement.

Lean Six Sigma in Research & Design: Quick Wins and Real Stats

- Parallel design + test removed 7 days per iteration in a med-device program.

- Standardized digital checklists cut drawing errors 48 %.

- Root-cause on lab delays turned a 75 % cycle-time cut into US $3 m annual savings.

Lean Six Sigma in Research & Design: Step-by-Step Start-Up

- Select one pain point — e.g., prototype turnaround.

- Map the current flow — include every hand-off and wait.

- Label each step as value-adding, required, or waste; delete pure waste.

- Baseline metrics — days, defects, labor hours.

- Analyze causes — 5 Whys, Pareto, regression.

- Pilot fixes — small team, one project.

- Control — lock SOPs, dashboards, and weekly audits.

Wrap-Up

Lean Six Sigma in Research & Design turns inventive ideas into reliable, fast-to-market products. Start with one metric, remove waste, reduce variation, and repeat.

Lean Six Sigma Yellow Belt Certification Course

Buy Now for $12.99

Udemy prices may vary depending on applied coupons and promotional events.

- 🧑🏫 136 lectures

- ⌚ 10h 55m total length

- 🗃️ 31 downloadable resources

- 📜 Certificate of completion

- 👩🎓 11,951 students

- ⭐ 4.6 rating by 671 students