Table of Contents

Business improvement is all about focusing your efforts on those areas of the business which will give you the greatest and most impactful outcomes. It is an approach which focuses on tackling the issues plaguing your business to guarantee a positive ripple effect across it. Improving one part of your organization can lead to changes and improvements in departments far and wide, with this ripple even hitting your customer in a positive way.

It is a great approach to take within your business because by reducing errors in a system you free up time for more value adding activities. By removing steps from a process you enable your products to get to your clients quicker. By upskilling your teams in certain areas you increase your outputs and productivity levels by, say, 20%. All of these don’t just have their immediate impacts but, as was mentioned before, their ripple effect impacts across the wider business.

With that said, the ripple effect of things going wrong, of processes becoming bloated and wasteful and colleagues being unhappy also have ripple effects across the business. However, these ripple effects are negative, and can lead to increased complaints from customers, loss of revenue from decreasing sales, increased turnover of staff – to name but a few. Therefore, delivering effective business improvement is extremely important.

But where do you start? How do you start? There are a number of business improvement options out there, but how do know which one is the right one for you? How do you know which is going to be the most impactful, delivered the quickest or have lasting positive consequences? In this article, we are going to document 5 business improvement options available to all. These options are those that you could seek to deploy readily, and you can start the ball rolling on these today. Let’s explore.

1: Review your processes

One of the most common challenges faced by organizations when it comes to improving their processes and operations is that they can’t actually see them – what is going on in them, how they are deployed and the challenges they face. To start to deliver business improvement within your organization, map out your key processes today.

This will involve getting the right people into a room and running a process mapping workshop. Map out those processes which are crucial to your organization in full, end to end. You should map out all of the key steps and activities, the hands offs and decision points, the starting and ending points, the departments, people and systems involved. Everything should be documented.

You should then overlay any problems, issues, errors etc. you are seeing from this process on a regular basis. You can overlay these onto your process map so you can see clearly where they sit, what is potentially causing them, their impacts and potentially the solutions you could deploy to fix them. The great thing about doing this activity is that you have a great level of insight and information with which you can make more informed decisions about what you need to do to improve your operational performance.

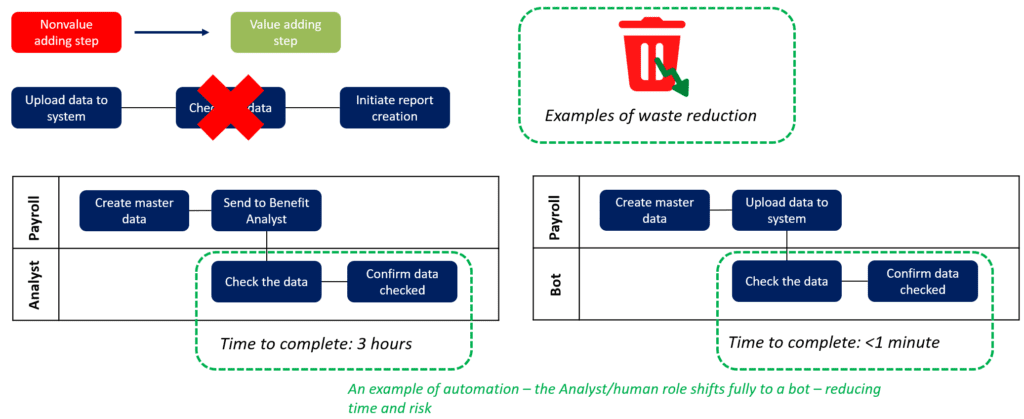

You can now conduct a full analysis of your processes, working out where there is excessive waste, where there are bottlenecks and rework loops and where the majority of any of your problems are coming from. This enables you to identify clearly what steps need to be removed, reformed or reengineered for the benefit of the wider organization. This is an activity you cannot conduct without this level of information, so you can now start to improve your business performance relatively quickly.

2: Upskill team members in improvement methodologies

Depending on the approach you take, a relatively quick win in this business improvement space could be upskilling team members on the very approaches that can secure you with small and big improvement wins. There are a range of improvement methodologies out there that you can deploy in your business, both for short and long term effect. Some of these approaches require much bigger investments of time and effort to get the teams upskilled and knowledgeable on the approaches. Others, less so.

For the quicker wins, train your team up on tools first and foremost. These tools can include process improvement tools such as flowchart mapping, value stream mapping, the 8 wastes, process analysis, value and non-value adding analysis etc. These tools can be learnt and deployed in a relatively short space of time. Indeed, you can train out process analysis on Monday, map the process on Wednesday and have your recommendations ready by Friday.

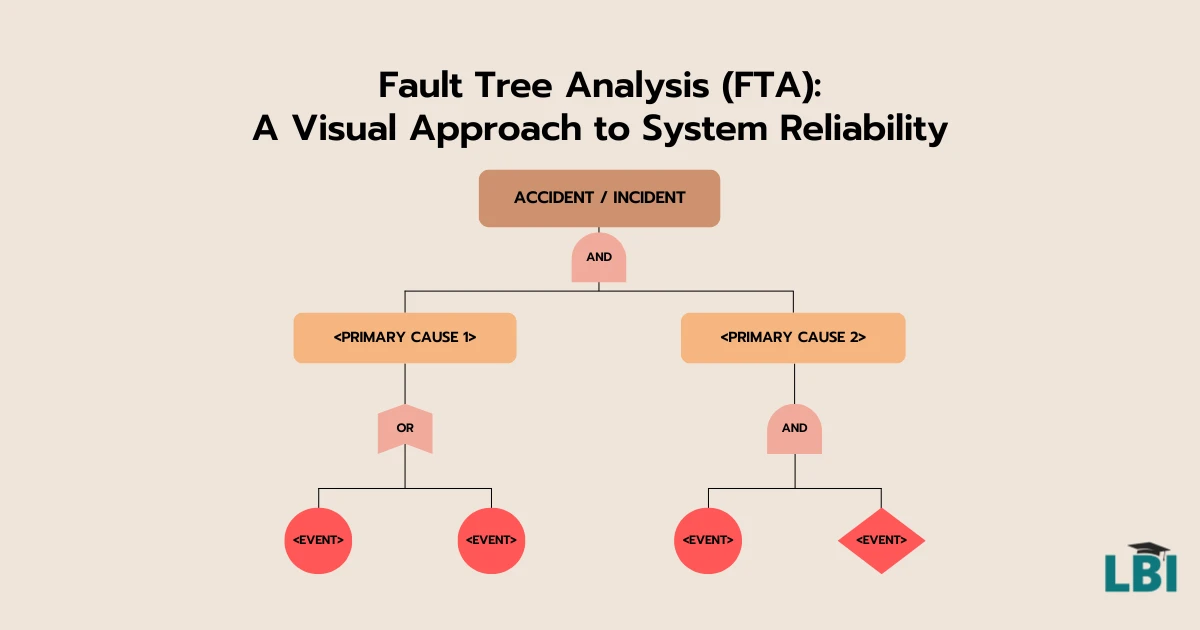

Other quick wins can include the root cause analysis space. If you want to empower your colleagues to not just report on problems plaguing your business, but identify the root causes and potential solutions to fix these, upskill them in root cause analysis tools. These could include the 5 Whys Diagram, the Fishbone Diagram, the Drill Down Tool, all root cause analysis tools that can be quickly learnt and quickly deployed. Starting fixing your problems today, not just one at a time, but several at a time, across your teams.

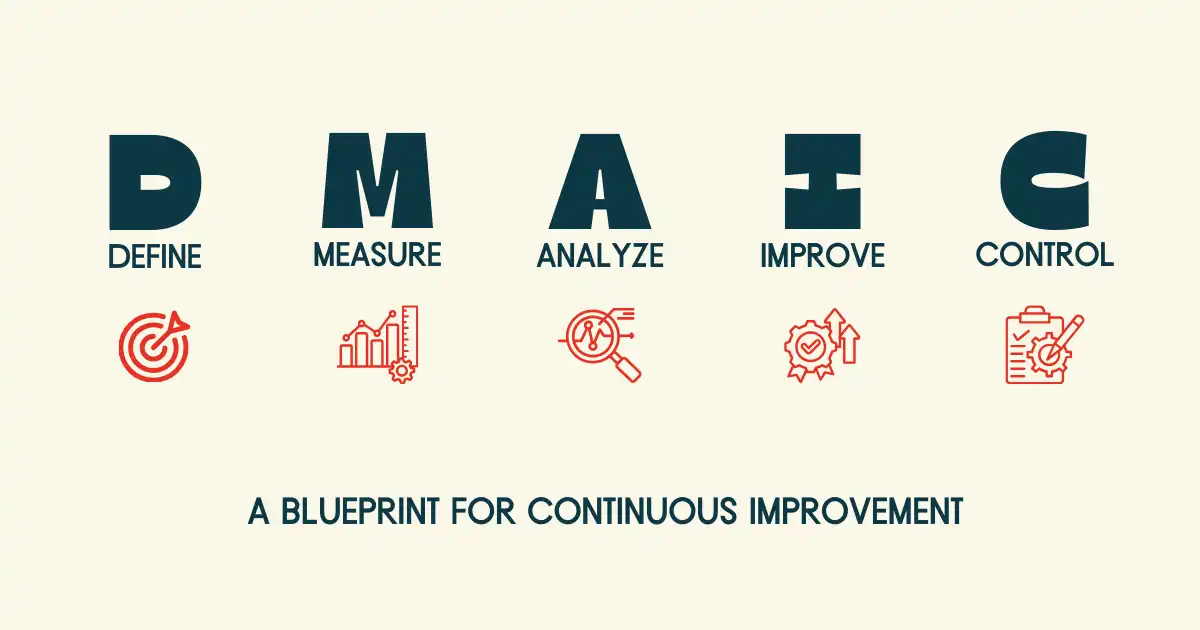

Longer term, you could build out quality and improvement programmes. These are often delivered in the Lean Six Sigma structure, utilising both the tools found in this methodology and the project management DMAIC approach. This approach has a relentless focus on the improvement of quality, reduction of issues and errors and delivery of more stable and capable processes. Depending on the level of training you seek, and whether you use internal or external expertise, the time it takes for the training to be completed and deployed can vary. What often follows the deployment of this training are for those who participated to start delivering low level improvement projects which, overtime, become bigger and more impactful projects.

3: De-silo and open up

One key problem plaguing many organizations is how disconnected the various teams, departments and operations that make them up are. This is known as operating in a silo, where the teams that make up an organization conduct their activities without consideration of their impact on other parts of the business. It means that teams don’t communicate with each other effectively, mean lessons are not learned, knowledge isn’t shared and solutions not collaboratively delivered. The impact of all of this is an organization prone to errors, issues and waste, significantly more than those that are open, transparent and de-siloed.

In order to de-silo, you can embed the following activities within your organization:

- Hold a regular meeting of the wider teams. This could involved delegates from each of the departments who then feed any information they receive back into their own teams, or could involve all team members.

- To accommodate any additional meetings or communication amongst departments, review meetings currently held on a regular basis and find ways to reduce how long they take, the value adding nature of these or find ways to involve others in these meetings.

- Share information and updates more readily. This could include process maps, so people understand better where they sit in the wider process and their impact on other departments. The sharing of updates, changes, new solutions etc. coming down the line. Greater involvement in projects and the deployment of new systems, technologies and solutions that impact the wider organization.

- Ensure org charts are readily available and are up to date so people have no excuse not to know who does what where and why. This increases the chance of collaboration as people know better who they should actually be collaborating with.

- Buddy up. The buddy up scheme would see individuals from different departments buddy up with each other. This would involve a regular coffee or catch up to discuss a set of regular questions, discussing updates from the teams, challenges being faced and lessons learned. This ensures a constant exchanging of ideas and current challenges.

Wherever you see friction points between the various departments within your organization or identify that people “are not in the know”, tackle these head on.

4: Start an error / issue log

This option is important for the knowledge and information it gives you. Far too often, organizations see a range of errors, issues and problems plague their most important processes, their products and services, and apply quick fixes. This is the wrong approach because recording these errors enables lessons to be learned and knowledge shared. When building out your error / issue log, be sure to record the following:

- What the error / issue was.

- Where it occurred (which process, department).

- When it occurred.

- The type of error (data, technology, people).

- The root cause of the problem (once discovered).

- The immediate fix put in place.

- The longer term solution put in place

- Any controls put in place to ensure the solution lasts the test of time.

- The individual who reported the problem.

- The individual now responsible for ensuring the problem does not occur again in the future.

Having all of this information means you can make decisions, decisions that can ultimately impact your organization for the better. You can understand the trends in terms of the type of errors you have been seeing, at what time of the year you are more likely to see them or their impact on the business. All of this enables you to find the right solutions for them today, but also plan adequately for the future, ensuring these don’t occur again in the future.

With this information, you can start to conduct business improvement projects today to put the right fixes and long term controls in place.

5: Hold improvement sessions with your team

Another way to get great information and insight to empower you to make better decisions is to extract it from your teams directly. This can come in the form of surveys, observations or interviews, but one of the most effective ways to do this is a workshop. A workshop will see you getting all of your key stakeholders OR those that are running your processes and delivering your services into one room. The reason for the workshop can vary. You may be bringing people together to discuss a specific problem they are facing. You may be discussing the process, mapping it out and conducting a process analysis. You may be having a general conversation about the direction of the department, discussing concerns and brainstorming solutions to address these.

Whatever it is, holding these types of workshop have a huge benefit. The key here is to conduct these types of workshop regularly. This can be whenever a set of problems or issues arise, whenever a change is identified as needed OR when the team just wants to kick off a bit of a reset. If you choose to conduct them regularly, every 3 – 6 months is a good idea. That way, they are not too onerous, remain fresh and give teams the time to think through the problems they are facing, the changes they want to see and how they want to see them implemented.

To hold an improvement session, you want to focus on the following key steps:

- Identify the process you want to reform or problem you need to address.

- Gather the right people into the room.

- Create an agenda which makes reason, activities and outcomes clear.

- Open the workshop by pulling up a clear definition of the problem / process in question.

- Map out the process / problems in question.

- Discuss in detail the challenges, their impacts and where they are located.

- Discuss root causes, potential solutions and a way forward.

- Leave the workshop with a list of activities to aid in the delivery of positive change.

These workshops are effective for many reasons. Firstly, you open up the conversation, promoting dialogue across departments and people about topics they may have been fearful of discussing before. Secondly, you generate a range of ideas and improvement suggestions people, on their own, may not have thought about. This promotes innovation and the expansion of creative thought. Third, colleagues and departments feel involved, engaged with, empowered. This is great for colleague retention, personal and professional development and helps expand the skills and experiences of all involved.

Conclusion

The 5 business improvement ideas laid out in this article are 5 of many, but all are extremely impactful. The biggest benefit you get from the majority of these is information. Information is readily available in organizations, in the minds of colleagues, the experience of customers and the processes which deliver the products and services. However, all too often this information is stuck, is not seen and is therefore not transferable to help you make better, more informed decisions. Business improvement is at its most successful when it gives you insightful information with which you can make better, more long term decisions.

If you start to deploy some of these business improvement ideas within the coming weeks, it is guaranteed that you will start to see actionable and tangible benefits to your processes, people and products.