Table of Contents

Opening Argument: Bottleneck vs. Waste—What’s the Real Enemy?

Every business wants to improve. That’s where Theory of Constraints (TOC) and Lean come in. Both are big names in process improvement. But they fight different enemies.

TOC focuses on bottlenecks—the one thing slowing everything down. It says: Find the slowest step. Fix it. Repeat.

Lean fights waste—anything that doesn’t add value. It says: Cut the fat. Make everything flow.

Both want results. Both boost profits. But their playbooks are different.

TOC says:

“A chain is only as strong as its weakest link.”

Lean says:

“If it doesn’t add value, it’s waste.”

Here’s the real question:

Do you want to move fast through your narrowest point? Or do you want the whole stream to be clean and clear?

There’s no wrong answer—just different goals, different tools, and different results. This blog breaks down when each method shines, and why your success depends on choosing the right one at the right time.

Round 1 – Core Philosophy

TOC’s Argument: Focus Beats Diffusion

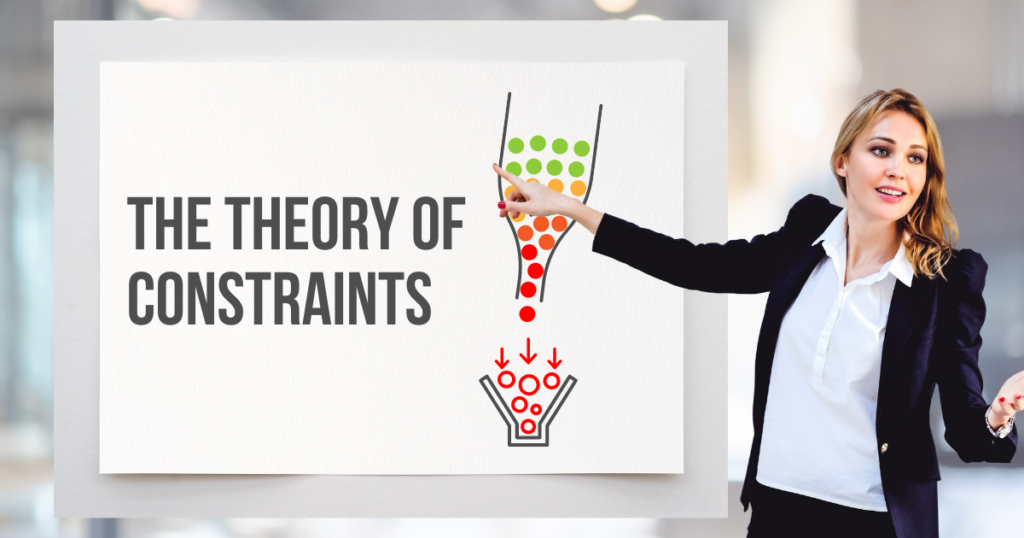

TOC works like a laser—zeroed in on one thing: the constraint. That’s the slowest step, the bottleneck, the blocker.

Fix that, and the whole system speeds up.

Eliyahu Goldratt, who created TOC, put it simply:

“A chain is only as strong as its weakest link.”

That’s the mindset. You don’t fix everything. You fix what matters most—the constraint.

TOC uses five clear steps:

- Find the constraint.

- Exploit it (use it fully).

- Subordinate everything else to it.

- Elevate it (upgrade, invest).

- Start over—there’s always a new weakest link.

This is strategic precision.

No scattered efforts. No wasted motion. All eyes on the choke point.

Lean’s Counter: Waste Is the Silent Killer

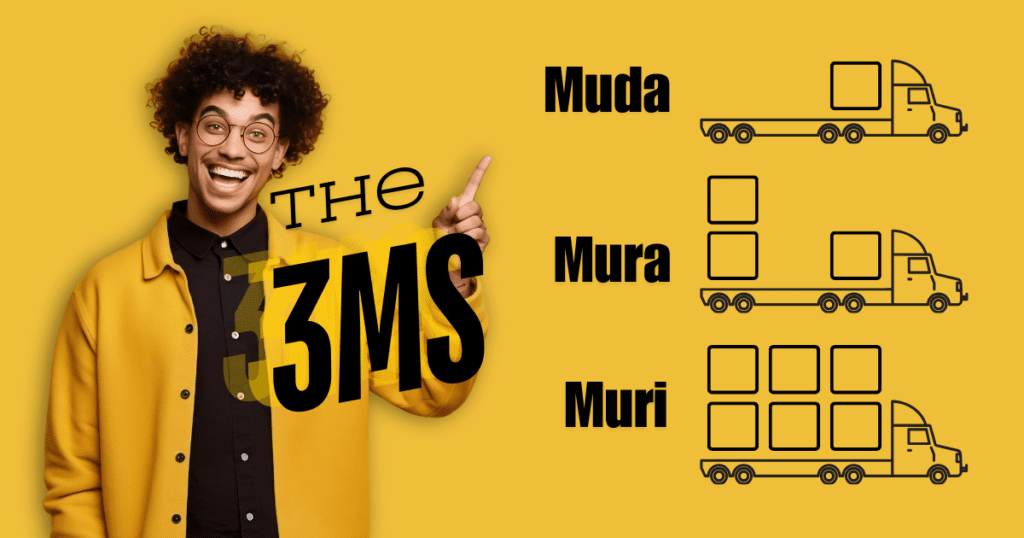

Lean sees things differently. It doesn’t hunt for one problem. It looks at everything.

Lean asks:

“Is this adding value for the customer?”

If not—it’s waste. Cut it.

Lean’s five principles aim for a clean, smooth system:

- Define value (from the customer’s view).

- Map the value stream.

- Make value flow.

- Pull from demand.

- Seek perfection—always improve.

Waste is sneaky. It hides in delays, overwork, bad layouts, unused talent. That’s why Lean fights it everywhere.

This is holistic discipline.

Not just fixing one problem. It’s fixing how the whole machine runs.

Bottom line:

- TOC says: “Fix the bottleneck, and everything improves.”

- Lean says: “Fix everything that doesn’t add value.”

Different lens. Different battlefield. Same goal: a better business.

Theory of Constraints | Certification Course

Buy Now for $9.99

Udemy prices may vary depending on applied coupons and promotional events.

- 🧑🏫 43 lectures

- ⌚ 3h 52m total length

- 🗃️ 1 downloadable resource

- 📜 Certificate of completion

- 👩🎓 7,655 students

- ⭐ 4.6 rating by 172 students

Round 2 – Speed vs Sustainability

TOC’s Advantage: Fast ROI, Low Investment

TOC is built for speed. It’s like emergency surgery for your business process: find the blockage, fix it, get results—fast.

Most TOC implementations show clear gains in as little as three months. That’s not theory—it’s field-tested. Why so quick?

- You don’t need to fix everything, just the constraint.

- You don’t need big budgets—just a sharp focus.

- You don’t need to retrain your whole team, only enough to apply the five focusing steps.

No complex tools. No culture shifts. Just logic and discipline.

This makes TOC perfect for businesses that need quick wins with minimal resources. It’s lean in effort—even if it’s not Lean in philosophy.

Lean’s Defense: Slow, But Built to Last

Lean takes its time. That’s because it doesn’t just fix the flow—it changes the thinking behind the flow.

The Toyota Production System, the origin of Lean, didn’t happen overnight. It was built on:

- Respect for people

- Long-term vision

- Relentless small improvements

Lean requires cultural buy-in—from the CEO to the shop floor. It’s a mindset, not just a method.

That’s why Lean is slower at first. But once it takes hold, it builds systems that keep improving themselves—even without a consultant in the room.

“Build people first, and they’ll build the business.” – Toyota principle

Final punchline:

- TOC gets fast results with focused effort.

- Lean creates lasting change with deep cultural roots.

Quick wins or long-term stability? Your move.

Lean Management | Certification Course

Buy Now for $9.99

Udemy prices may vary depending on applied coupons and promotional events.

- 🧑🏫 61 lectures

- ⌚ 3h 51m total length

- 🗃️ 13 downloadable resource

- 📜 Certificate of completion

- 👩🎓 12,657 students

- ⭐ 4.7 rating by 511 students

Round 3 – Local Fix or Global Flow?

Lean’s Point: Think Big, Act System-Wide

Lean doesn’t just zoom in—it zooms out. It treats the whole organization like one interconnected flow. Every step, every handoff, every delay—it’s all part of the picture.

That’s why Lean uses value stream mapping. It shows how work moves from start to finish, across departments, not just inside them. You don’t just fix a step—you redesign the entire flow.

Lean tools like 5S, Kanban, and Kaizen are made to work across the board—from the factory floor to finance.

“Optimize the whole, not the parts.”

This means global thinking. Even small waste, if repeated often enough, hurts the whole system. So Lean doesn’t ignore anything—it shines a light on everything.

TOC’s Rebuttal: Fix What’s Broken, Not What’s Visible

TOC says, hold on.

Just because something is visible doesn’t mean it’s important.

Fixing a smooth-running department is like fixing a flat tire on a car that’s out of gas—it doesn’t help.

TOC focuses only on the real constraint—the one thing that slows down the entire process. That’s where the impact is. And that’s where you get the biggest return for your effort.

“Don’t optimize ten things that don’t matter. Optimize the one that does.”

And here’s the kicker: fixing that one bottleneck often lifts the performance of the whole system. No need to touch every process.

So, the split is clear:

- Lean says: Map everything. Improve everywhere.

- TOC says: Find the choke point. Fix that first.

Global visibility vs. local leverage. Which lens fits your business better?

Round 4 – When They Clash

TOC Says: Keep Some Buffer. Don’t Force Balance.

TOC is clear: perfect balance is a trap.

Trying to make every part of the system equally fast doesn’t work. Why? Because real-life processes have variation—breakdowns, rework, delays. If every step runs at full capacity with no buffer, one hiccup shuts the whole thing down.

TOC prefers to keep buffers—small pockets of slack before and after the bottleneck. These help absorb the chaos and keep the constraint working at full speed.

“The constraint is the drum. Buffers are the shock absorbers.”

This “unbalanced” design makes sure the bottleneck—the thing that limits your output—never stops. Everything else plays backup.

Lean Says: Balance the Flow. Buffers = Waste.

Lean thinks differently. Flow is king.

Any time you have idle workers, waiting materials, or inventory stacking up—that’s waste. Lean’s ideal is a balanced line, where each process step runs in sync with customer demand (takt time).

Buffers? Lean calls them a band-aid for deeper problems like poor maintenance or uneven workloads. The goal is one-piece flow—smooth, even, predictable.

“Fix the cause, not the symptom.”

The Clash: Smooth Flow vs. Strategic Slack

Here’s where they bump heads:

- Lean balances lines, which can hide the constraint—you won’t always see where the true slowdown is.

- TOC looks for the constraint, but to keep it running, it deliberately unbalances the system.

So:

- Lean says: Eliminate buffers.

- TOC says: Use buffers to protect what matters.

Which is better? It depends:

- If your system runs like clockwork, Lean’s balance works.

- If you’re dealing with real-world messiness and chaos, TOC’s buffers might save you.

Both are right—but not at the same time.

Round 5 – When They Click

Here’s the truth: TOC and Lean don’t have to fight. In fact, they work even better together.

TOC Finds the Constraint

TOC is your compass. It tells you where to look. What to fix first.

It answers the big question: What’s holding us back the most right now?

That’s where your effort goes. No guesswork. No wasted improvement projects. Just focus.

Lean Tools Help Fix It

Once TOC points to the constraint, Lean steps in with the toolbox:

- 5S brings order to the workspace.

- SMED (Single-Minute Exchange of Dies) cuts setup times fast.

- TPM (Total Productive Maintenance) keeps machines running.

These tools don’t just fix the constraint—they make it stronger, faster, more reliable.

TOC says “What’s broken?”

Lean says “Here’s how to fix it right.”

TLSS: The Best of All Worlds

This combo even has a name: TLSS – TOC, Lean, Six Sigma.

- TOC gives direction.

- Lean provides tools for flow and waste removal.

- Six Sigma handles variation and quality control.

Together, they create targeted, efficient, and high-quality improvement.

Use TOC as the Compass. Use Lean as the Toolkit.

Don’t waste time optimizing what doesn’t matter.

Let TOC guide you to the constraint.

Then bring in Lean to attack it with precision.

This isn’t compromise—it’s synergy.

Smart businesses don’t choose sides. They combine forces and win faster.

Round 6 – The Human Factor

Lean Wins on Culture

One of Lean’s strongest traits? It puts people first.

At its core, Lean is about respect for people—not just managers, but the workers closest to the problems. It sees employees as problem solvers, not just button-pushers.

- Workers help design solutions.

- Teams run continuous improvement (Kaizen) themselves.

- Leaders coach instead of command.

This builds trust, buy-in, and long-term cultural change. Everyone is part of the fix—not just watching it happen.

“Without people, there is no Lean.” — Toyota philosophy

Lean doesn’t just improve processes. It transforms how people think and act inside a company.

TOC Lags Here

TOC? Not so much.

Its strength is logic and speed, not soft skills. Most TOC projects start with top-down change: identify the bottleneck, fix it, repeat. The reasoning is sound, but the rollout often skips emotional buy-in.

In The Goal, the team follows Jonah’s guidance because the logic makes sense. But in real life, change isn’t that simple.

Critics say TOC can:

- Overlook culture and resistance.

- Treat people like parts in a system.

- Focus on throughput more than empowerment.

That doesn’t mean TOC can’t work with people—it just wasn’t built with culture at the center.

Bottom line:

- Lean makes people part of the system.

- TOC focuses more on fixing the system.

If you want fast gains, TOC delivers.

If you want people to own the gains, Lean shows the way.

Final Verdict: It Depends—But Not on You

So, which one wins—TOC or Lean?

Answer: It depends. But not just on you. It depends on your situation, your team, your urgency, and your starting point.

If You Need Speed: TOC Wins

TOC is built for urgent change.

It gives you a clear target—the constraint—and tells you to focus there, fast.

No full system redesign. No waiting for cultural buy-in. Just fix what’s broken and watch results follow.

Perfect for:

- Crises

- Quick turnarounds

- Businesses that need ROI now

If You Need Depth: Lean Wins

Lean is a system-wide strategy. It looks at the big picture and goes deep—across processes, departments, and people.

Yes, it takes time. But it builds habits, not just fixes. It creates organizations that get better on their own.

Perfect for:

- Complex environments

- Long-term growth

- Cultures ready to evolve

If You Have a Team: Culture Matters

- Lean needs buy-in. It’s collaborative, people-driven, and built on shared purpose.

- TOC can start anywhere. It’s logical, top-down, and fast-moving—even in tough environments.

So What’s the Final Word?

“TOC tells you where to look. Lean tells you how to fix it.”

They’re not rivals—they’re partners.

Use TOC to find the leverage point.

Use Lean to build a system around it.

Use both, and you don’t just improve—you improve smart.

Ready to take action?

Start simple:

- Pick your biggest workflow pain point.

The one that slows everything down or just feels messy. - Ask yourself:

- Is this a bottleneck—one point choking the whole flow?

- Or is it just bloated with waste—extra steps, delays, or confusion?

- Choose your fighter:

- If speed is your goal, start with TOC.

- If system-wide clarity is the need, go with Lean.

- Or better yet—use both. Let TOC point the way, and let Lean do the fixing.

Want to go deeper and make it official?

🎓 Enrol in our Udemy courses:

- Master Theory of Constraints

- Apply Lean principles with real-world tools

- Earn certification to boost your career or business credibility

Make smarter improvements. Get recognized for it.

Start learning now—and turn workflow headaches into results.