Table of Contents

Introduction

The journey towards a lean and productive workplace often begins with the adoption of the 5S methodology. This system, which hails from Japan, involves five strategic steps aimed at organizing workspaces for peak efficiency, effectiveness, and safety. Embracing 5S helps in significantly reducing waste, enhancing the quality of work, and elevating employee satisfaction. By integrating 5S into daily routines, organizations can create a structured environment that supports continuous improvement and lean management principles.

The 5Ss: An Overview

The 5S methodology is built on five key principles, each represented by a Japanese word: Sort (Seiri), Set In Order (Seiton), Shine (Seiso), Standardize (Seiketsu), and Sustain (Shitsuke). Let’s delve into each “S” to understand its role in fostering an organized workplace.

The 5s is a powerful tool to deploy Continuous Improvement in your organization. We have discussed this in our Continuous Improvement course. Check it out.

Sort (整理 – Seiri)

Sort is all about decluttering the workspace by removing unnecessary items.

Importance: By eliminating unneeded materials, tools, and equipment, you create a streamlined environment where only essential items are present. This reduces distractions and makes it easier to focus on the task at hand.

Examples: Imagine going through your office desk. You might find old documents, broken gadgets, redundant stationery, and irrelevant paperwork. By sorting through these and keeping only what you need, you can work more efficiently.

Challenges and Solutions: A common challenge is the difficulty in deciding what to keep and what to discard. This can be tackled by categorizing items based on their frequency of use. Questions like, “Have I used this item in the past month or year?” can help in making the decision to keep or discard.

Set In Order (整頓 – Seiton)

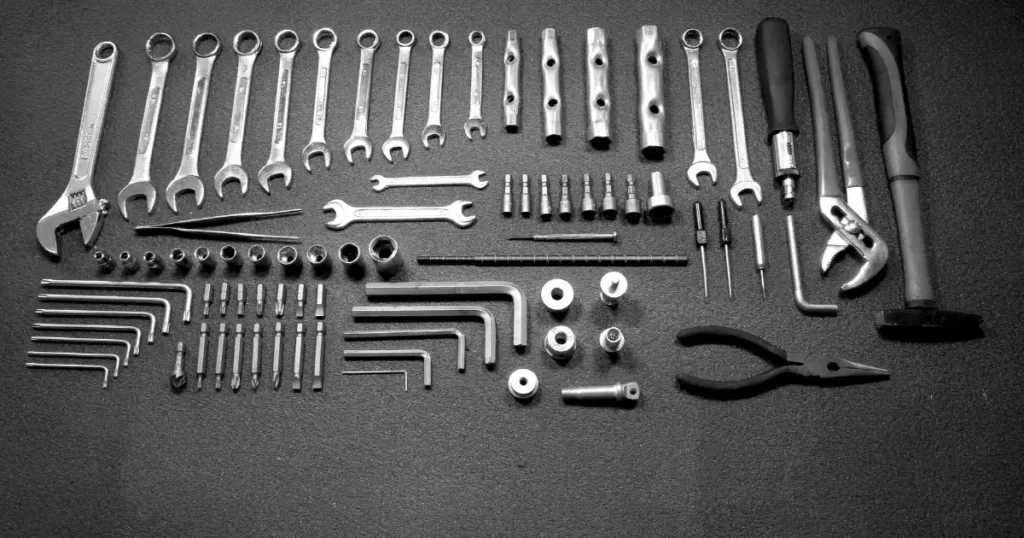

Set In Order involves organizing the necessary items so that they are easy to access and use.

Importance: This principle aims to reduce the time spent searching for tools, documents, and materials. It ensures that everything has a designated place, which minimizes wasted effort and enhances productivity.

Examples: Consider a mechanic’s workshop. If tools are scattered everywhere, valuable time is wasted looking for the right wrench or screwdriver. By using pegboards with labelled outlines for each tool, everything can be stored in an orderly manner.

Challenges and Solutions: Determining the ideal locations for items can be tricky. Start by observing the workflow and placing frequently used items in easily accessible spots while less frequently used items can be stored further away. Colour-coding and labelling can also aid in quick identification.

Shine (清掃 – Seiso)

Shine focuses on keeping the workspace clean and well-maintained.

Importance: Regular cleaning prevents dirt and clutter from accumulating, which can lead to malfunctions and safety hazards. A clean environment also boosts morale by providing a pleasant place to work.

Examples: In an office setting, employees can be assigned daily five-minute clean-up tasks at the end of the day. In a factory, machines can be wiped down and floors swept regularly.

Challenges and Solutions: Maintaining a regular cleaning schedule can be challenging. Implementing checklists and assigning specific roles for cleaning tasks can help ensure consistency. Encouraging everyone to take ownership of their designated areas promotes a collective responsibility for cleanliness.

Standardize (清潔 – Seiketsu)

Standardizing means establishing and maintaining uniform procedures and guidelines.

Importance: Consistency is key in ensuring that the first three steps (Sort, Set In Order, Shine) are maintained over time. Standardized procedures eliminate ambiguity and ensure that everyone is following the same best practices.

Examples: Standard operating procedures (SOPs) can be created for routine tasks, such as how to handle certain machinery or maintain cleanliness standards. Visual workflows or step-by-step guides can be displayed prominently.

Challenges and Solutions: Employees may initially resist new standardized procedures. Frequent training sessions and open communication about the benefits of these standards can foster compliance. Regular audits can also help in identifying deviations and areas for improvement.

Sustain (躾 – Shitsuke)

Sustain is about embedding the 5S methodology into the company culture.

Importance: To sustain the gains made from 5S, it’s crucial to integrate these practices into everyday operations. This prevents regression to old habits and ensures long-term improvement.

Examples: Regular 5S audits, feedback sessions, and team meetings can help reinforce the principles. Recognizing and rewarding adherence to 5S practices can also motivate employees to continue following the methodology.

Challenges and Solutions: The most significant challenge is maintaining enthusiasm and commitment over time. Leadership plays a crucial role in this. Managers and team leaders should lead by example and keep the momentum going through regular encouragement and visible commitment to 5S practices.

Benefits of Implementing 5S

Improved efficiency and productivity: An organized workspace means less time spent looking for tools, documents, or materials, allowing more time to be dedicated to productive activities.

Enhanced safety: A tidy workplace reduces risks such as tripping over clutter or equipment failures due to improper maintenance.

Better workplace morale: Employees feel more valued and motivated in a clean, organized environment. This boosts overall job satisfaction and can lead to increased retention rates.

Challenges in Implementing 5S and How to Overcome Them

Resistance to change: Change can be intimidating. Overcome this by clearly communicating the benefits of 5S, involving employees in the process, and providing the necessary training and support.

Lack of understanding or training: Ensure that everyone understands the 5S principles through comprehensive training sessions and continuous education.

Sustaining the momentum: Keeping the 5S principles alive requires ongoing efforts. Regular audits, feedback, and leadership support are crucial in maintaining the practice.

Also Read: Problems of implementation 5 S practices in an industrial company

Conclusion

The 5S methodology is a powerful tool for creating an efficient, clean, and safe workplace. By implementing Sort, Set In Order, Shine, Standardize, and Sustain, organizations can foster a culture of continuous improvement that benefits both employees and the company. Start small, involve your team, and continue to reinforce the 5S principles. You may be surprised at the positive impact it can have on your work environment.

FAQs

What does 5S stand for?

The 5S methodology consists of Sort, Set In Order, Shine, Standardize, and Sustain, which are steps to organize and improve workplace efficiency.

Why is 5S important?

5S is important because it helps eliminate waste, improves productivity, enhances safety, and boosts employee morale by creating an organized and clean work environment.

How can I start implementing 5S?

Begin with a small area or a pilot project, involve your team, and follow the five steps: Sort, Set In Order, Shine, Standardize, and Sustain. Utilize training sessions and regular audits to maintain the practice.

What are common challenges with 5S?

Common challenges include resistance to change, lack of understanding, and maintaining the process over time. These can be overcome through effective communication, training, and continuous reinforcement of 5S principles.

Can 5S be applied outside of the workplace?

Absolutely! 5S can be applied to any environment. Whether it’s organizing your kitchen, garage, or personal workspace, the principles of 5S can help make any area more efficient and enjoyable to use.