Table of Contents

Root cause analysis is a powerful tool which, if delivered correctly, can yield significant benefits for an organization. Knowing how to deliver root cause analysis is, however, just half the task here. You also need to know when the best time is to deliver root cause analysis. You need to know which scenarios, settings and situations need to be present to require you to deliver root cause analysis.

Where and when you deliver root cause analysis can have a direct impact on how successful it is. Indeed, many times people can deliver a root cause analysis activity without great success and wonder why they haven’t seen the outcomes they expected. This can be directly linked to delivering the root cause activity in the right place, at the right time, for the right reasons.

In this article, we will explore just when it is the right time to deliver root cause analysis, and for what reason you would want to do this.

What is root cause analysis?

Root cause analysis is the active pursuit of insight into why something has happened, whether that be good or bad. It is a process you must follow to unpick what you have found out, what has happened, why it has happened and what you are going to do to fix it. It is a set of tools you can use to map out the potential root causes of something, whittling these down from potential root causes to the one or two actual root causes. It is a methodology that asks questions, delivers insight and enables you to make more informed decisions.

The questions you will ask with root cause analysis is “Why did this happen? What caused this to happen? Where did this come from?” If Y=f(x) where Y is the output, f is the process and (x) are the inputs that go into the process, you will want to focus on the inputs, the (x) to understand why they are leading to the output you have seen. This output can be your product, process or problem.

So when?

To understand when you need to deliver root cause analysis, we approach this in two ways. Are you delivering it because you are REACTING to something, or are you delivering it to be PROACTIVELY preparing for something? The reactive vs. proactive split is well known when it comes to root cause analysis, and the reasons behind why you would want to deliver a root cause analysis exercise can often be bucketed into these two camps. Let’s explore them now.

Using root cause analysis REACTIVELY

When it comes to reactive root cause analysis, it’ll usually be the case that something has happened, and the initial response to it is: “Why has this happened?” This would indicate a root cause analysis is required to answer that question.

A change in quality

If you or your customers begin to notice a decrease in the quality of your products or services, this could indicate something is wrong. Problems plaguing processes or the people that deliver them will eventually make their way to the outputs of your processes, impacting your customers, brand and reputation. Therefore, if you see a change in quality, more defects in the services you are delivering or broken parts on the products you are shipping, you need to react to this with a root cause exercise to understand why this has happened, and what you can do to fix it.

Increased customer complaints

Tied very much to the previous reason, if you notice an increase in customer complaints but don’t quite understand why they are rising, you need to root cause. In many instances when it comes to increased customer complaints, organizations will by default anticipate that they fully understand why these complaints are rising. Comments such as “teething problems with the new launch” or “holiday time, it happens” can often be banded around. It is only when the complaints continue to rise do they realise there is something more sinister at play, and a root cause analysis exercise is needed to find the actual reasons and the long-term fixes.

A slowing process

One of the needs for reactive root cause analysis that can often be overlooked is a process which is taking longer to deliver its stated outputs. As organizations grow and evolve, so too do their processes. Part of this evolution can include additional steps and activities, checks and balances (and ultimately, waste) being added into operational processes. All of these changes often happen naturally, without forethought, are not documented and therefore can lead to challenges. All of this can lead to processes delaying, it taking longer to complete activities or waiting for others to complete their work. Pinpointing the areas of your process where this is happening is relatively easy, understanding exactly why is harder – hence the need for reactive root cause analysis.

Errors are occurring

Whether in your process, in the products or services you are delivering or how all of this is being done, if you are noticing errors, mistakes and problems arising, you need to know why. For example, if you create a monthly finance report and the data on that report has a 90% accuracy rating, why is the other 10% of data present on that report incorrect? Where is the problem occurring which is causing all of these errors? Often with errors that are coming from systems or technologies are harder to understand, therefore reactive root cause analysis is the best approach.

Changing dynamics in your culture

Reactive root cause analysis can also be used when it comes to the people working in your organization. If you are seeing issues within your teams or processes, is it the people that are causing this? If you are seeing errors in the work being done, is human error to blame for this? The people element needs to be root-caused as humans are very unpredictable elements in the delivery of a process, and therefore you need to be as reactive as ever when it comes to people. This also extends to the culture of your business. If you notice the culture-shifting in any way, a reactive root cause analysis could be needed. This could include a less productive culture, a more toxic culture, a less collaborative culture, a fearful culture etc. A shifting culture (shifting to the negative) leads to a significant ripple effect across your business, your processes, products and people. Therefore, reactively root causing why this is happening quickly and delivering your solutions rapidly is crucial.

Understanding root cause analysis PROACTIVELY

When it comes to proactive root cause analysis, it’ll usually be the case that you are trying to predict or pre-empt something that has not yet happened, but you think it may. It is a form of control whereby you test out the potential for problems, errors and issues in certain scenarios to give you the insight you need before such an event occurs.

When designing a new process

If you are looking to deliver a brand new process into your organization, you will need to understand the risk around this process. That is where proactive root cause analysis comes into play. Given the new process has never been delivered before, you need to test and understand where there could be friction points, pain points, the potential areas where errors or issues could arise. You want to ensure you can anticipate these potentially occurring before they do, reducing or completely removing any risk and impact in the future. The proactive root causing activities here gives you insight, insight which can be translated into solutions to be deployed today, before any problems arise.

When reforming a current process

If you are engaged in a process improvement project, you may also need to use proactive root cause analysis. The reason here is to ensure that any changes you make to your current process (the removing of steps, new systems or technologies, the changing of department or owner etc.) does not have a determinantal impact further down the process. If you are reforming your process siloed, without consultation of other players or stakeholders, you may need to take this approach. Here, you can test the newly reformed process approach by seeing where potential issues could arise, and root causing why they would be occurring. This means, as part of your reforming efforts, you can then build into the new process the right measures to ensure no problems can arise due to your changes.

Control measures

Proactive root cause analysis is also a control measure in itself. A control measure is something you do or something you put in place within a process or product to ensure something does not go wrong. Examples can include peer reviewing someone’s work or building control charts to monitor the stability and capability of your processes, spotting any potential issues before they arise. With proactive root cause analysis, you are simply seeking to understand where something could go wrong, so you can target that part of your product or process with the right solution to stop it. In this sense, the root cause analysis activities you conduct are giving you insight and information you did not previously have, and therefore are steering you to the most appropriate solutions.

Test solutions and ideas

As well as building out new processes, the delivery of solutions identified to rectify current problems plaguing your processes need to be tested also. Even though you have identified a solution you want to deploy, this does not necessarily mean it will absolutely work as expected. Some sort of testing will be needed to ensure it will last the test of time. In this instance, you can deploy your solution into the process BEFORE it goes LIVE, and test the process with the solution in place. Proactive root cause analysis here will enable you to test the solution, showing you if there are any gaps or holes in your approach or if the solution would fall at the first sign of trouble. This approach is similar to control measures for your process, but your instilling control measures for your new solutions.

Organizational culture

One of the great things that proactive root cause analysis gives you is insight. Insight to make better decisions, insight to make changes and insight which gives you the confidence that what you are delivering now is going to work for the long term. This insight also extends to your people and the culture of the business. Proactive root cause analysis here enables you to test changes in your organizational structure that may impact the culture of the business. You can test whether a new org structure is going to have a detrimental impact. What would be the response to this? What will be the impact of new training in the business, aimed at breaking down barriers and getting people working new collaboratively? What would be the impact of a new colleague charter, team away days, buddy schemes etc. All of these activities that can be delivered from a cultural change perspective can be assessed and addressed through proactive root cause analysis.

Conclusion

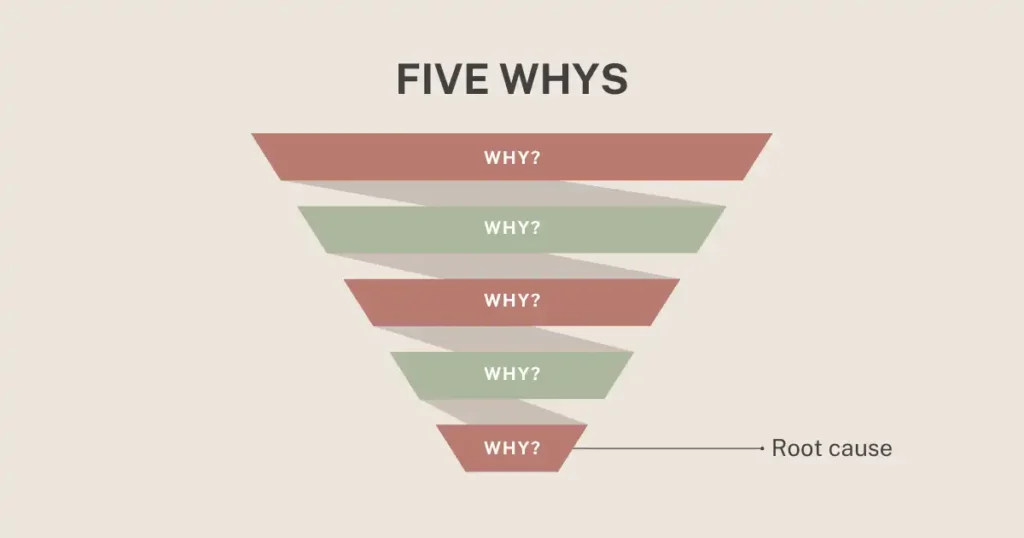

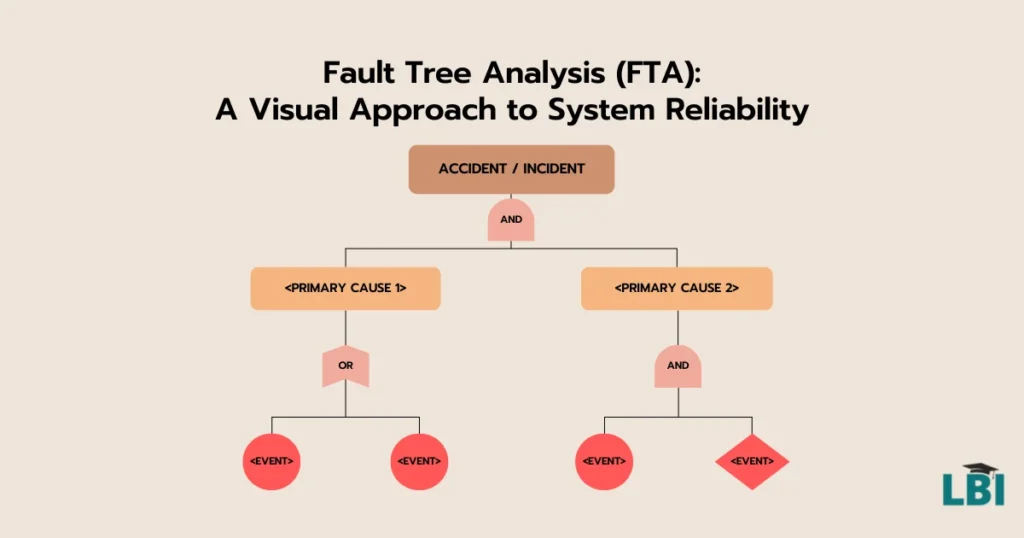

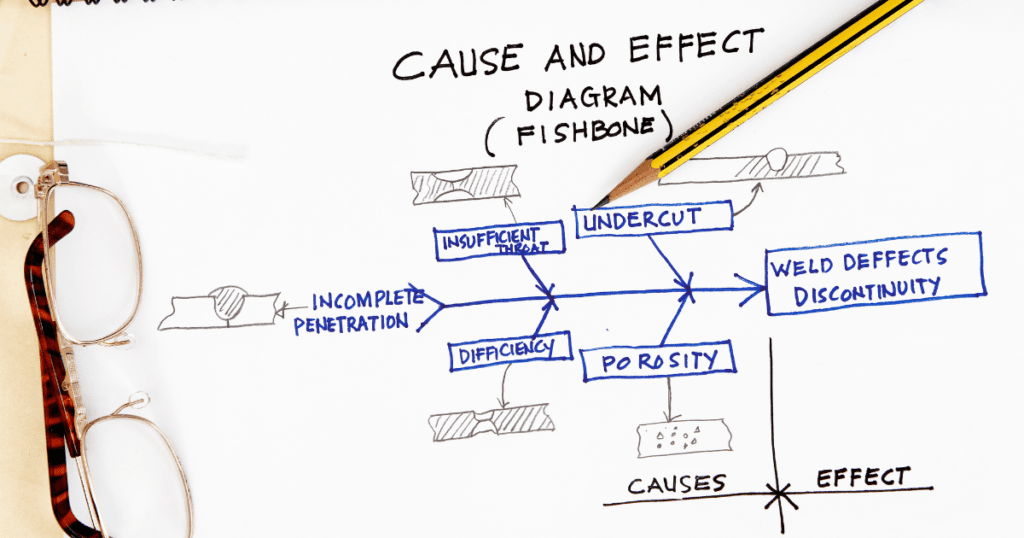

When it comes to delivering root cause analysis, you are spoilt for choice in terms of the tools you could use. We have the Fishbone Diagram, 5 Whys Diagram, Drill Down Tool Pareto Chart, FMEA etc. all of which can be used at different times and for different purposes. Equally, you are blessed with a structured methodology and approach that can be deployed both readily and over a period of time, for short term or long term benefits, by a team of novices or an expert.

Whichever approach you take, and however you decide to deliver your root cause analysis activities, just ensure you are clear on the why. Why are you doing this? What do you want to the outcome to be? Once you are clear on this, you can be clear on your approach – are you being reactive or proactive?